- three or two-jaw puller;

- mandrel from the cup puller kit for pressing out the front bearing.

Disassembly

1. Remove the generator from the car (see above).

2. Remove the voltage regulator and capacitor (see "Voltage regulator and capacitor - check and replacement").

3. Ring wrench by 8 mm unscrew the three bolts connecting the terminals of the stator windings to the rectifier unit (1), and another bolt securing the rectifier unit (2) (note how the insulating and thrust washers are installed).

4. Carefully bend the wire of the stator winding leads to the side.

5. Using a Phillips screwdriver, unscrew the capacitor mounting screw.

6. Remove the rectifier unit along with the capacitor. socket wrench by 10 mm unscrew the two nuts of the contact bolt. We remove the remote and insulating bushings from the bolt, remove the bolt from the rectifier unit and remove the capacitor tip from the contact bolt.

7. Mark with a marker the relative position of the front and rear covers of the generator (to simplify assembly).

8. socket wrench by 8 mm unscrew the four bolts that tighten the front and rear covers of the generator.

9. With a slotted screwdriver, gently push the covers of the generator.

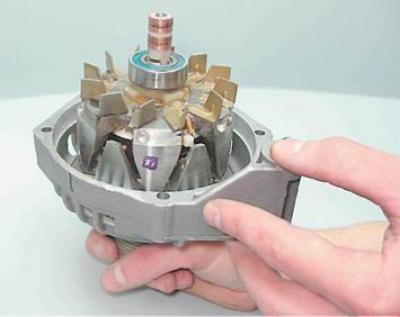

10. Disconnect the back cover along with the stator winding from the front cover.

Recommendation. To determine the technical condition of the rear bearing, shake from side to side and vigorously rotate its outer ring. The bearing should not have significant play, and the ring should rotate freely without jamming and extraneous noise. A defective bearing must be replaced.

11. Mark the stator with a marker (to indicate its position relative to the back cover).

12. We take out the stator from the rear cover of the generator.

Recommendation. To determine the technical condition of the front bearing, hold the pulley with your hand, shake it from side to side and rotate the front cover. If the bearing seizes, has significant play, or makes noise when the cover is vigorously rotated, then it must be replaced.

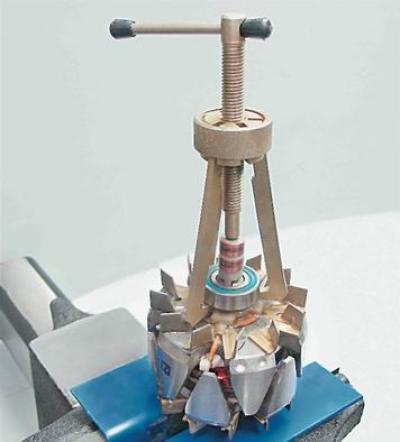

Advice. The manufacturer recommends changing the front rotor bearing along with the front cover of the generator, as it is rolled into the cover. But, given that the cost of the bearing is much lower than the cost of a new front cover, and even more so the generator assembly, it is advisable to press out and replace the faulty bearing.

13. If it is necessary to replace the front bearing of the generator with a socket wrench by 24 mm unscrew the pulley fastening nut, holding the pulley with sliding pliers.

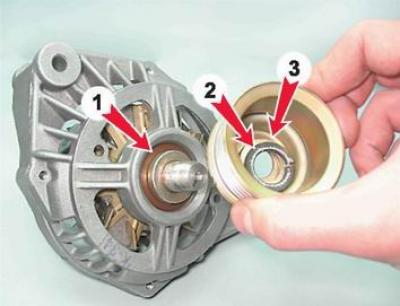

14. Remove the pulley with spring from the rotor shaft (3) and flat washer (2), spacer (1).

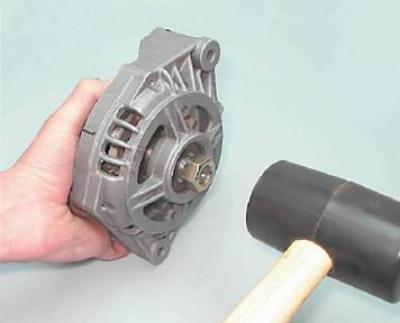

15. We screw the pulley fastening nut onto the threads of the rotor shaft (flush with end). By blows of a hammer with a rubber striker on the nut, we press the rotor out of the front bearing.

16. Install the front cover in a vise (The jaws of the vise must be fitted with soft metal pads).

17. Having selected suitable mandrels from a set of cup puller, we press the bearing out of the seat in the front cover.

18. If it is necessary to replace the rear bearing of the generator, we fix the rotor in a vice with soft pads on the jaws. Using a universal puller, we press the rear bearing from the rotor shaft.

Examination

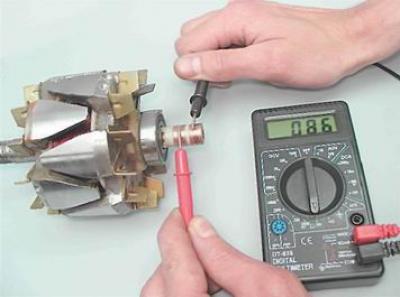

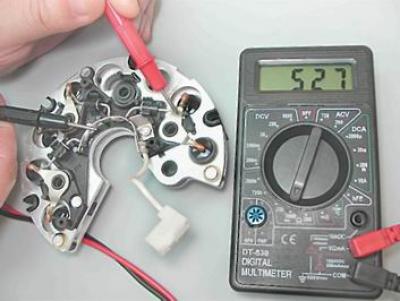

1. Check the stator windings: a) applying the ohmmeter probes to the slip rings of the rotor, we check the excitation winding for an open circuit. The resistance of a healthy excitation winding should be 5-10 ohms;

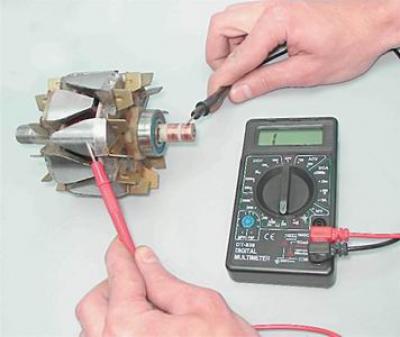

b) connecting the ohmmeter probes to any slip ring and to the rotor, we check the excitation winding for a short circuit to "mass". With a good rotor winding, the ohmmeter should show an infinitely large resistance.

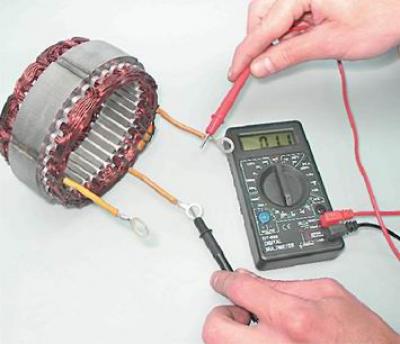

2. Check the stator windings: a) alternately connecting the ohmmeter probes to the terminals of the stator winding, we check the winding for an open circuit. In the absence of a break, the ohmmeter will show a small electrical resistance (about 10 ohm);

b) by connecting the ohmmeter probes to any terminal of the winding and to the stator, we check the stator winding for a short circuit to "mass". If there is no short circuit, then the ohmmeter should show infinite resistance.

3. Check the rectifier unit:

Comment. A good semiconductor diode conducts electricity in only one direction. A diode is faulty if it does not conduct current or conducts current in both directions.

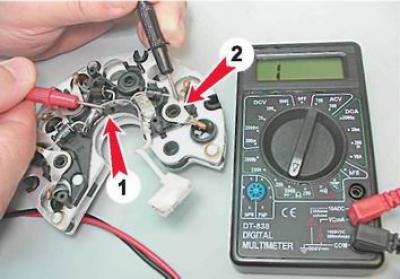

A) connect the positive lead of the ohmmeter (in diode test mode) to common bus of auxiliary diodes (1), and the negative terminal probe - to the output of the tested diode (2). A good diode should not pass current (resistance tends to infinity);

b) swap tester probes. If the diode is good, the ohmmeter should show resistance (several hundred ohms). Similarly, we check the other two auxiliary diodes;

V) we connect the probe of the negative output of the ohmmeter to the plate of the rectifier unit, into which the tested diode is pressed, and the probe of the positive output to the diode output. A good diode should not pass current (resistance tends to infinity);

G) swap tester probes. If the diode is good, then the ohmmeter should show a resistance of several hundred ohms).

Similarly, we check other power diodes.

Faulty rotor, stator must be replaced. If one or more diodes in the rectifier unit are faulty, the unit assembly must be replaced.

Assembly

Warning! Before pressing the front bearing of the generator into place, it is necessary to check the seat of the bearing and, if necessary, restore the chamfer with a knife or scraper where the edges of the hole have remained jammed. When pressing the front bearing into the cover, the force must be transferred only to the outer ring of the bearing.

1. Having selected suitable mandrels from the cup puller set, we press the new front bearing into the seat in the front cover until it stops.

Warning! In the following operation, apply only light blows with the hammer. Strong blows can crack the cover made of brittle aluminum alloy.

2. Using a hammer and a steel drift of a suitable diameter, we restore the rolling of the bearing in the cover.

Warning! Before installing the alternator rear bearing, make sure that the rotor shaft is securely clamped in a vise. Place a wooden block of a suitable size under the rotor shaft so that the front impeller of the rotor is not damaged during pressing. To avoid damage to the bearing, strikes should only be applied to the inner ring.

3. Using a piece of pipe of suitable diameter (deep head can be used by 19 mm) press the new bearing onto the rotor shaft until it stops.

Further assembly of the generator is carried out in the reverse order. At the same time, we combine the marks applied to the covers and the generator stator. We finally tighten the coupling bolts evenly, crosswise, in several stages of half a turn. After tightening the bolts, we make sure that the rotor rotates easily (rotor jamming may be due to skewed caps). Before tightening the stator winding bolts, make sure that insulating washers are installed under their heads.

Warning! When installing the voltage regulator, do not apply side forces to the brushes.