- viewing hole or flyover;

- household steelyard.

Comment. In the absence of an inspection ditch and overpass, work can be done by removing the right front wheel (see "Preparing the car for maintenance and repair" And "Wheel - replacement"). Belt tension can be determined from above (from the engine compartment), but this requires practical experience, since access to the upper branch of the belt is hindered by the right support of the power unit.

Execution sequence

1. Remove the engine mudguard (see "Mudguard of the engine - removal and installation").

Comment. If you perform work without an inspection ditch, you can not remove the mudguard - just remove the right mudguard of the engine compartment (see "Mudguards of the engine compartment - removal and installation").

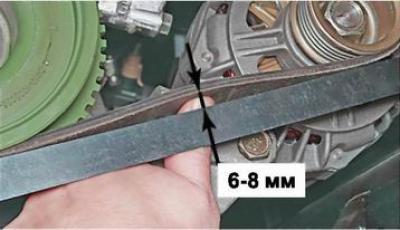

2. We apply a force of 98 N (10 kgf) to the alternator belt exactly in the middle between the alternator pulley and the engine crankshaft pulley.

Advice. If it is difficult to estimate the force created by the hand, you can use a household steelyard with a maximum load of 10 kg.

Recommendation. A correctly adjusted belt should bend 6-8 mm. If the belt deflection is not correct, adjust the belt tension.

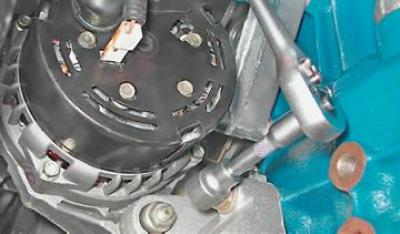

3. Ring wrench or socket wrench by 13 mm with a ratchet, we loosen the tightening of the nut of the bolt of the lower mounting of the generator.

4. In the engine compartment with a box wrench by 13 mm loosen the tensioner nut.

5. Rotating ring wrench by 10 mm adjusting bolt, adjust belt tension (clockwise to increase the tension of the belt, and counterclockwise to decrease).

Warning! Excessive belt tension can lead to failure of the alternator front bearing

6. We check the tension of the alternator belt and, if necessary, repeat the adjustment.

7. After making sure that the belt is tensioned correctly, with a ring wrench by 13 mm tighten the tension bar nut.

8. socket wrench by 13 mm tighten the nut of the bolt of the lower mounting of the generator.

9. Install the removed parts (engine mudguard or mudguard and wheel).