- flat horizontal platform (preferably near the wall of the house, fence or gate);

- tape measure 5 m long;

- cardboard sheet (to cover the headlight when adjusting).

Recommendations. Adjustment is desirable to carry out in the dark. The vehicle must be in running order (fully loaded and without additional cargo). Since it is not easy to find a suitable surface as a screen, it is better to use a 1x2 m plywood shield with markings applied to it. In this case, it is necessary to prepare an emphasis or stand in order to install the shield vertically.

Execution sequence

1. We install the car on a flat horizontal platform perpendicular to the surface selected as a screen, and at a distance of 5 m from it. You can install a sheet of plywood in front of the car under the same conditions.

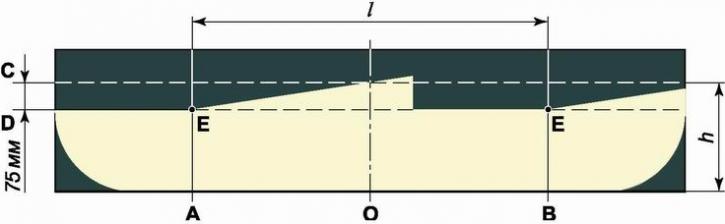

2. We mark the screen according to the figure.

Screen layout for headlight adjustment: A - a vertical line indicating the location of the low beam lamp of the left headlight; B - a vertical line indicating the location of the low beam lamp of the right headlight; C - a horizontal line indicating the location of the dipped beam headlights; D - line indicating the height of the horizontal border of the beams of light; O - center line; l is the distance between the dipped beam headlights; h is the distance from the surface of the site on which the car is installed to the dipped beam headlights

Comment. The headlamp lenses are labeled to indicate the centers of the low beam and high beam sections. Based on them, you can make the necessary measurements with a tape measure.

3. Check the tire pressure, if necessary, bring it to normal.

4. Turn the headlight hydrocorrector drive knob to the position corresponding to the minimum vehicle load.

5. We seat the assistant in the driver's seat. Then we vigorously shake the car from the side to self-adjust the suspension.

6. Turning on the dipped headlights, close one of the block headlights, for example, the right one, with a sheet of cardboard.

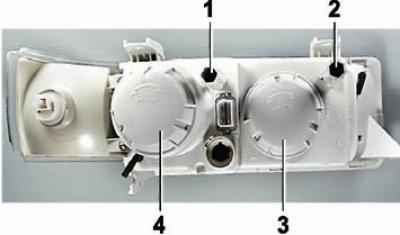

7. Turning the knob of the adjusting screw (1) of the left block headlight, we bring the horizontal border of the light beam to line C, and then, turning the adjusting screw (2), combine the break of the border of the light beam with line A.

The location of the adjusting screws and sections on the left block headlight: 1 - screw for adjusting the beam of light in the vertical plane; 2 - screw for adjusting the light beam in the horizontal plane; 3 - cover of the high beam section; 4 - low beam section cover.

Note. On the right block headlight, all elements are located symmetrically.

Adjust the right headlight in the same way.