- valve grinding tool;

- rubbing paste.

Execution sequence

1. We prepare the car for work (see "Preparing the car for maintenance and repair").

2. Remove the cylinder head (see "Cylinder head for 2112 and 21124 engines (16v) - removal and installation", or see "Cylinder head for 2111 and 21114 engines (8v) - removal and installation").

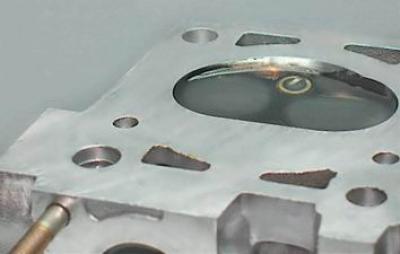

3. To check the tightness of the valves of the block head, lay it on a horizontal surface with the mating plane up.

4. We fill the combustion chambers of the block head with kerosene and wait a few minutes. If the level of kerosene in any chamber drops, then one or more valves are leaking.

Comment.The check is shown on the example of an 8-valve engine block head. On a 16-valve engine, the check is carried out similarly.

5. Remove the valve stem seal (see "Valve stem seals for 2112 and 21124 engines (16v) - replacement", or see "Oil seals for engines 2111 and 21114 (8v) - replacement").

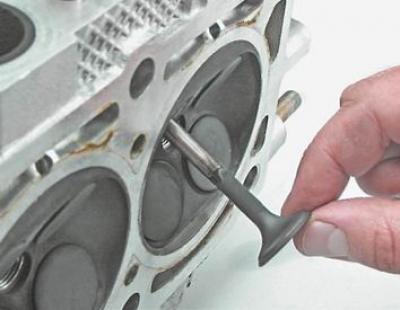

6. Remove the valve from the guide sleeve.

Comment.The operation is shown on the example of a 16-valve engine block head. On an 8-valve engine, the operation is carried out similarly.

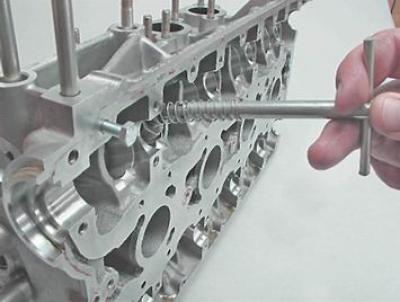

7. Apply lapping paste to the working edge of the valve.

8. We install the valve in the head of the block and fix the device for lapping the valves on its stem.

9. Pressing the valve to the seat, turn it from side to side. After 10-15 strokes turn the valve 90°and continue lapping.

Comment.The operation is shown on the example of a 16-valve engine block head. On an 8-valve engine, work is carried out similarly

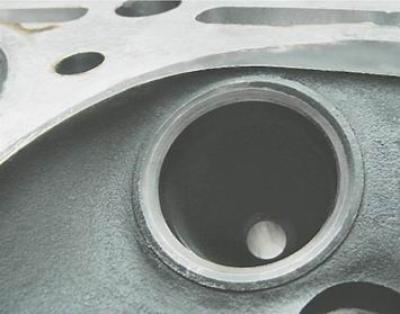

10. Lapping is carried out until a uniform annular mark is formed on the valve disc...

...and on his saddle.

11. Carefully remove the remnants of lapping paste from the valve and its seat. Install the valve in reverse order.

12. Similarly, grind the rest of the leaky valves.