Comment. The timing belt should be replaced every 45,000 km on 16-valve engines and every 75,000 km on 8-valve engines.

To complete the work you will need: hex wrench by 5 mm (for 16 valve engines), key by 10 mm (for 8-valve engines).

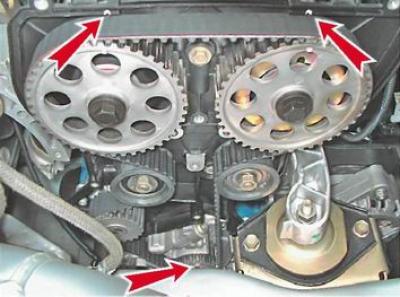

Camshaft drive scheme: 1 - toothed pulley of the crankshaft of the engine; 2 - tide on the cover of the oil pump; 3 - toothed pulley of the coolant pump; 4 - tension roller; 5 - gear pulley of the exhaust camshaft; 6 - rear timing belt cover; 7 - a gear pulley of a camshaft of inlet valves; 8 - guide roller; 9 - toothed belt; A - TDC mark on the crankshaft toothed pulley; B - mark on the oil pump cover; C, F - mark on the rear cover of the timing belt; D - mark on the gear pulley of the exhaust camshaft; E - mark on the toothed pulley of the intake camshaft

16 valve engines

Comment. Operation is shown on the 21124 engine. On the 2112 engine, the front cover is not divided into upper and lower parts.

Removing

1. We prepare the car for work (see "Preparing the car for maintenance and repair").

2. For convenience, remove the adsorber and set it aside. Without disconnecting the hoses from it, remove the bracket for its fastening.

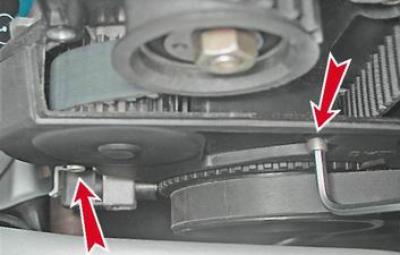

3. Hex key by 5 mm unscrew the five bolts securing the upper part of the front cover of the timing belt.

4. Remove the top of the cover.

5. Using the same key, unscrew the two bolts securing the lower part of the front cover.

6. Remove the lower part of the front cover.

7. Remove the front right wheel (see "Wheel - replacement") and put the car on a secure stand.

8. Remove the right mudguard of the engine compartment (see "Mudguards of the engine compartment - removal and installation").

9. Turning the crankshaft with a socket wrench at 17 or 19 mm for the pulley mounting bolt, set the piston of the first cylinder to the TDC position of the compression stroke. In this case, the marks of the crankshaft pulleys and camshafts will be aligned with the alignment marks on the oil pump housing and the timing belt rear cover.

10. Remove the crankshaft pulley (see "Crankshaft pulley - removal and installation").

Comment. To remove the belt, it is enough to unscrew the tension roller nut a few turns and loosen the belt tension. However, it is more convenient to remove and put on the belt on the pulleys when the tension and guide rollers move freely along the studs

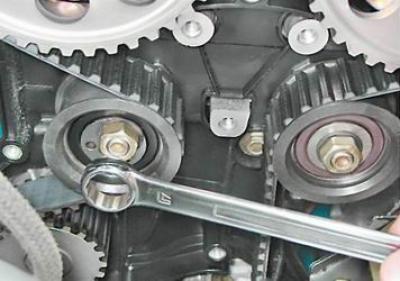

11. Key by 17 mm unscrew the nuts securing the tension and guide rollers.

12. Remove the belt.

13. Rotating the tension and guide rollers, check their condition. The roller, which has play and makes a lot of noise during rotation, is replaced.

Installation

1. We put the belt on the crankshaft pulley, making sure that the pulley mark is aligned with the mark on the oil pump housing.

2. We pass the left branch of the belt from the outside of the coolant pump pulley and the inside of the tension roller. We skip the right branch from the inside of the guide roller.

Comment. If there is a device for fixing the camshaft pulleys, install it and put the belt on the pulleys, preventing its right branch and the area between the camshaft pulleys from sagging.

If there is no fixture, it should be noted that after removing the toothed belt, the intake camshaft pulley under the action of their springs will turn one tooth clockwise, and the exhaust ones - counterclockwise.

3. Key by 17 mm turn the intake camshaft pulley counterclockwise until the marks on the pulley and cover are aligned. Having chosen the sagging of the right branch of the belt, we put the belt on the exhaust camshaft pulley.

Without giving the belt a chance to jump over the pulley teeth, let the pulley return to its original position (turn one tooth to the right).

4. Key by 17 mm turn the exhaust valve shaft pulley, setting it to a position similar to the position of the intake valve pulley (the pulley mark is one tooth away from the mark on the cover).

5. Holding the pulley in this position, we put the belt on its upper part, preventing the belt from sagging between the pulleys and jumping over the teeth of the intake valve pulley.

6. Turning the pulleys with a key by 17 mm, we stretch the right branch of the belt without allowing the crankshaft pulley to turn and completely put the belt on the exhaust camshaft pulley.

7. We check the alignment of the marks of all three pulleys in the TDC position of the compression stroke of the first cylinder (see above).

8. We stretch the toothed belt (see "Timing belt - checking and adjusting tension") and tighten the roller nuts.

9. Key by 19 mm for the pulley mounting bolt, turn the engine crankshaft two full turns, after which we again check the alignment of the marks of the crankshaft pulleys and camshafts with the alignment marks on the engine. If necessary, repeat the adjustment of the timing belt.

10. Reinstall the front timing belt cover, crankshaft pulley, alternator belt and parts removed during disassembly.

8-valve engines

Removing

1. We prepare the car for work (see "Preparing the car for maintenance and repair").

2. Key by 10 mm unscrew the three bolts securing the front cover of the timing belt.

Camshaft Drive Diagram: 1 - toothed pulley of the crankshaft of the engine; 2 - toothed pulley of the coolant pump; 3 - tension roller; 4 - rear timing belt cover; 5 - a gear pulley of a camshaft; 6 - toothed timing belt; 7 - tide on the cover of the oil pump; And - a label on a gear pulley of a cranked shaft; B - mark on the tide of the oil pump cover; C - protrusion on the back cover of the timing belt; D - mark on the camshaft sprocket

3. Raise the cover vertically upwards, and then remove it from the engine.

4. Remove the front right wheel (see "Wheel - replacement") and put the car on a secure stand.

5. Remove the right mudguard of the engine compartment (see "Mudguards of the engine compartment - removal and installation").

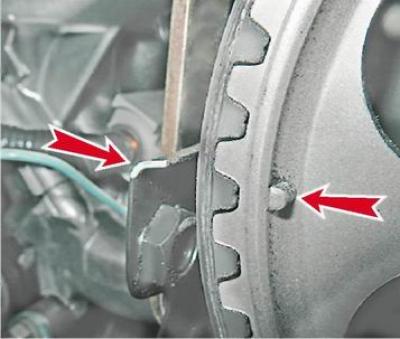

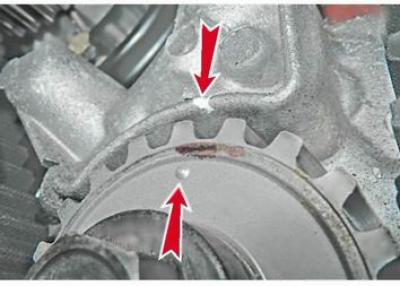

6. Turning the crankshaft with a socket wrench at 17 or 19 mm for the pulley mounting bolt, set the piston of the first cylinder to the TDC position of the compression stroke. This will align the camshaft pulley mark with the alignment tab on the rear timing belt cover.

7. Remove the crankshaft pulley (see below, "Crankshaft pulley - removal and installation").

8. We unscrew the nut of the tension roller and loosen the tension of the toothed belt as much as possible (see "Timing belt - checking the condition and adjusting the tension").

9. Remove the timing belt from the pulleys.

10. Rotating the tension roller, check its condition. The roller, which has play and makes a lot of noise during rotation, is replaced.

Installation

1. We check the coincidence of the marks on the crankshaft pulley and the tide on the oil pump housing.

2. We also make sure that the marks on the camshaft pulley and the protrusion of the rear cover of the timing belt match (see point 4 above).

3. We install a new belt in the following sequence: preventing the crankshaft and camshaft toothed pulleys from turning relative to the marks, we put the belt on the crankshaft pulley; slightly pulling the right branch of the belt, we put it on the camshaft pulley; we pass the belt from the inside of the tension roller and put it on the coolant pump pulley.

4. Adjust the belt tension (see "Timing belt - checking the condition and adjusting the tension").

5. We wrap the crankshaft pulley mounting bolt and, turning the engine crankshaft two turns, make sure that the marks on the pulleys and the engine match. Reinstall the belt if necessary.

6. Reinstall the crankshaft pulley and tighten the bolt

7. We reinstall the front cover of the timing belt, the alternator belt and the parts removed during disassembly.