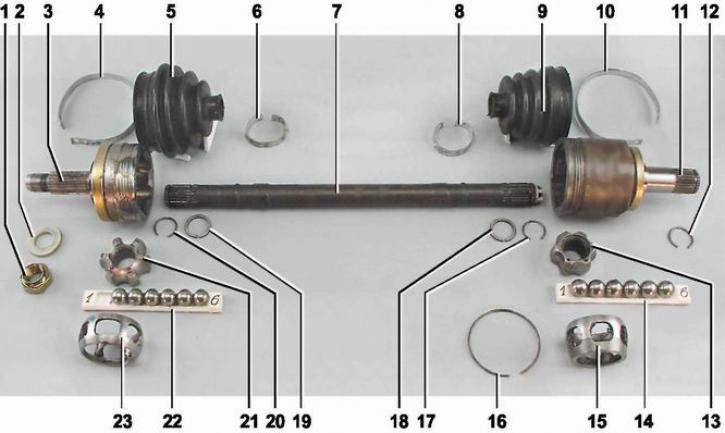

Left Drive Details: 1 - special hub nut; 2 - thrust washer of the nut; 3 - body of the outer hinge; 4 - a large collar of the outer hinge cover; 5 - protective cover of the outer hinge; 6 - small collar of the outer hinge cover; 7 - drive shaft; 8 - small collar of the inner hinge cover; 9 - protective cover of the internal hinge; 10 - a large collar of the inner hinge cover; 11 - body of the internal hinge; 12 - retaining ring of the shank of the inner hinge; 13 - inner race of the inner hinge; 14 - balls of the internal hinge; 15 - inner hinge separator; 16 - lock of the internal hinge; 17 - retaining ring of the holder of the inner hinge; 18 - thrust ring of the cage of the inner hinge; 19 - thrust ring of the outer hinge cage; 20 - retaining ring of the cage of the outer hinge; 21 - inner cage of the outer hinge; 22 - balls of the outer hinge; 23 - outer hinge separator.

Note. The shaft of the right drive is longer and made of a pipe.

When the cover breaks and adverse conditions (dirt, dust, snow) the hinge can become unusable for several tens of kilometers. A damaged protective boot can be replaced if the failure is discovered before the hinge fails. In this case, the hinge must be disassembled, washed and put in a new lubricant.

The wear of the outer joint may indicate clicks in the area of the front wheel hub when driving in a sharp turn. As the hinge wears, the clicks will increase and quickly develop into a constant crunch even when moving in a straight line. Untimely repair will lead to the destruction of the hinge.

Recommendation. The technical condition of the hinges should be checked every 10-15 thousand km. It is best to combine this procedure with an oil change when the car is on a flyover or inspection hole.

To perform the work, you will need an assistant, as well as a viewing hole or overpass.

Execution sequence

1. We prepare the car for work and (see "Preparing the car for maintenance and repair"), hang the front wheels of the car on stands and turn on the neutral gear.

2. We inspect the protective covers of the drive hinges, make sure that they are intact and that there is no leakage of lubricant from them.

3. Set the wheels in the direction of rectilinear movement. By hand we move and rotate the drive shafts in different directions. Thus, we make sure that there are no backlashes between the parts of the drives.

4. Rotating the front wheel by hand, we check the drive shaft for the absence of runout.

5. Alternately turning the front wheels in one direction or the other and rotating them, we make sure that there are no extraneous sounds (knock and crunch) in external and internal hinges.

Recommendations. In a serviceable hinge, the presence of extraneous sounds during operation or backlash between parts is unacceptable. Faulty hinge should be replaced (either separately or the entire drive assembly). A torn boot should only be replaced if the hinge is in good condition.