You can assess the technical condition of the suspension while the car is moving. When driving at low speed on uneven roads, the suspension should work without knocks, squeaks and other extraneous sounds. After driving over an obstacle, the vehicle must not sway.

Tip: Suspension checks are best combined with tire and wheel bearing checks (see "Wheels, tires and hubs" - one-sided wear of the tread on the outer or inner side of the tire indicates a violation of the adjustment of the wheel alignment angles in the front suspension).

To complete the work, you will need a viewing hole or overpass.

Execution sequence

1. We prepare the car for work (see "Preparing the car for maintenance and repair").

2. With the effort of the hands, we shake the upper part of the front wheel of the car in the transverse direction. Similarly, we check the front suspension on the other side of the car.

If you feel the backlash (even unobtrusive), then we check the reliability of fastening the steering knuckle to the front suspension strut and the condition of the hub bearing (see "Wheels, tires and hubs").

Recommendation: It is better to check the performance of shock absorbers after a long trip, while the working fluid in the shock absorbers has not cooled down.

3. Vigorously swing the front of the car body in a vertical direction. If, due to inertia, the body continues to oscillate (more than two movements - up and down), after it has stopped swinging, then one or both shock absorbers are faulty. To identify a faulty shock absorber, we repeat the test, applying force first on one side of the car, and then on the other.

Note: This test only detects defective shock absorbers. It is possible to check the effectiveness of vibration damping by shock absorbers only on a special stand.

4. We inspect the suspension struts - leakage of fluid from the shock absorbers is not allowed.

Recommendation: Shock absorbers should be replaced in pairs, even if the second front suspension shock absorber is in good condition.

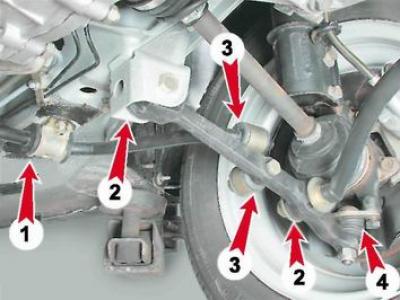

5. Visually check the condition of the pillows (1) and racks (3) anti-roll bar, rubber-metal hinges of levers and longitudinal stretch marks (2), ball bearing covers (4)...

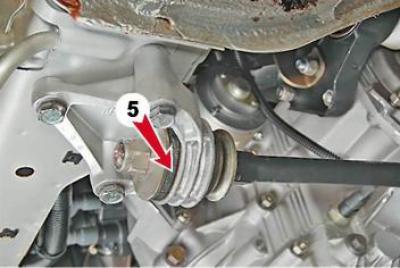

... pillows of transverse stretch marks (5).

Hinges and cushions with one-sided bulging of rubber, tears and cracks are replaceable (see relevant sections below).

6. We check the tightening of the nuts for fastening the suspension parts, if necessary, tighten them.

7. We examine the details of the suspension. Deformation and fatigue cracks in suspension parts are not allowed. We replace damaged parts.

8. We measure the distance between the brake disc and the transverse lever with a caliper. If, when rocking the body, this distance changes by more than 0.8 mm, then we replace the ball joint. Similarly, we check the ball joint of the other front suspension strut.