The starter armature shaft type 5712.3708 transmits rotation to the drive shaft through a planetary gear. The planetary gears of the reducer rotate on needle bearings.

The starter drive consists of a drive gear and an overrunning clutch. The drive can move along the helical splines of the drive shaft.

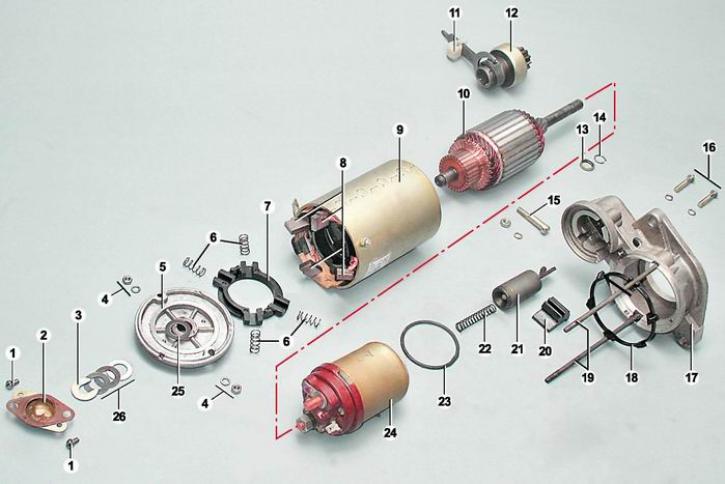

Starter details 2109.3708: 1 - screw for fastening the protective cap; 2 - protective cap; 3 - retaining half ring; 4 - nut for fastening the rear cover; 5 - back cover; 6 - brush springs; 7 - brush guides (outer part); 8 - brushes; 9 - stator; 10 - anchor; 11 - drive lever; 12 - drive; 13 - restrictive ring; 14 - retaining ring; 15 - axis of the drive lever; 16 - screws for fastening the traction relay; 17 - front cover; 18 - plastic sealing ring of the cover; 19 - tie rods; 20 - rubber plug; 21 - core of the traction relay; 22 - return spring; 23 - sealing ring of the traction relay; 24 - traction relay; 25 - thrust washer; 26 - shims

The traction relay is installed on the motor housing and is designed for remote switching of the high current consumed by the starter when starting the engine, and mechanical connection of the starter drive with the engine flywheel ring gear. The relay coil has two windings, retracting and holding.

When the ignition key is turned to position II ("starter") to the control output of the traction relay "50", and from it voltage is supplied to both windings of the relay from the battery. Under the influence of a magnetic field, the metal core of the traction relay, overcoming the force of the return spring, is drawn into the coil. At the same time, it drives the starter drive lever. The drive lever, with its horseshoe-shaped fork, extends the starter drive, introducing the drive gear into engagement with the engine flywheel ring gear. At the same time, a copper contact plate located in the plastic cover of the traction relay closes the contact bolts. Current begins to flow through the windings of the starter armature, the armature rotates, starting the engine.

The negative terminal of the solenoid winding of the relay is connected to "weight" through the starter armature windings (see diagram). After closing the contact bolts, the current stops flowing through this winding and the core of the traction relay is held by only one winding, this makes it possible to reduce the heating of the relay windings and reduce the power consumption at the time of starting the engine.

The overrunning roller clutch of the drive transmits rotation only in one direction - from the starter to the flywheel. After starting the engine, when the crankshaft speed increases sharply, the clutch protects the starter from destruction.

After the driver releases the switch key (castle) ignition, the output of the traction relay stops receiving the control voltage; the electromagnetic field holding the anchor disappears. The drive lever, under the influence of a spring, moves the starter drive back and disengages the drive gear from the flywheel crown. At the same time, the power contacts open, supplying current to the starter motor windings.

Warning! The starter is the most powerful consumer of electrical energy in a car. When starting the engine, the current consumed by the starter can reach more than 400 A. Therefore, all electrical connections between the battery and the starter must be in good contact.