Recommendation: The condition of the engine should be monitored regularly during the operation of the vehicle. Signs of malfunctions may be: the presence of oil drops in the parking lot of the car; ignition of the engine malfunction warning lamp or emergency oil pressure warning lamp, the appearance of an extraneous sound (noise, knock) during engine operation; smoky exhaust; moving the arrow of the temperature indicator to the red zone; increased oil consumption, noticeable loss of power. If at least one of the listed signs is detected, a more detailed check is necessary. Checks of the technical condition of engine systems are shown in the relevant sections of the chapter "Engine and its systems" (see "Cooling system - check of technical condition"; "Power supply system - check of technical condition"; "Engine management system - check of technical condition"; "System of release of the fulfilled gases - check of a technical condition").

It is possible to assess the technical condition of the engine with sufficient accuracy by external signs and with the help of available equipment (compression gauge, pressure gauge).

Execution sequence

1. We prepare the car for work (see "Preparing the car for maintenance and repair").

2. We inspect the engine from above and below (on a viewing hole or overpass). Oil leaks may indicate worn oil seals or oil pan seals.

3. We start the engine, while the emergency oil pressure warning lamp should go out. If the control lamp lights up at idle after the engine warms up, and goes out after increasing the crankshaft speed, then the oil pump gears, crankshaft journals, main and connecting rod bearing shells may be worn out. If the lamp is constantly on, then the lubrication system or the emergency oil pressure sensor may be faulty. We check the oil pressure in the engine lubrication system using a pressure gauge (see "Lubrication system - oil pressure check").

Warning! Operating the vehicle with insufficient oil pressure in the lubrication system will result in severe engine damage.

4. After warming up the engine, we listen to its work.

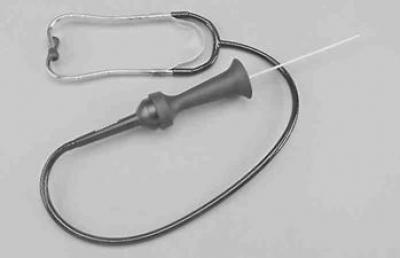

Recommendation: It is convenient to perform engine troubleshooting by ear using a technical stethoscope. With it, you can quite accurately determine the source of extraneous noise.

Attention! To avoid personal injury, do not touch the moving parts of the engine when performing the following operation (pulleys, belt) and do not touch hot parts of the engine.

5. If an extraneous sound appears with a stethoscope, we determine the area where this sound is most audible. By the nature of the sound and the place of sound emission, we determine the possible source of the sound and the possible malfunction.

Note: A clattering ringing sound under the cylinder head cover usually indicates increased valve clearances (see "Adjusting valve clearances in the timing drive"), uniform noise in the timing belt area may indicate wear on the tensioner pulley or water pump bearing. Knocks at the bottom of the cylinder block and from the sump side, which increase with increasing engine speed, are caused by a malfunction of the main bearings. In this case, as a rule, the oil pressure in the lubrication system is low. At idle, this sound is low-pitched, and as the speed increases, its tone rises. When you sharply press the gas pedal, the engine emits something similar to a growl - such as "gyr-r-r". Ringing knocks in the middle of the cylinder block are caused by a malfunction of the connecting rod bearings. Rhythmic metallic knocking in the upper part of the cylinder block, audible at all engine operating modes and intensifying under load, is caused by a malfunction of the piston pins. A muffled knock at the top of the cylinder block on a cold engine that subsides and disappears when warmed up can be caused by worn pistons and cylinders. Operating the vehicle with defective bearings and pins will result in engine failure.

6. If oil consumption has increased, and no leaks are found:

- We warm up the engine to operating temperature.

- Disconnect the crankcase ventilation hose from the throttle body.

- We bring a sheet of paper to the hose. If oil stains appear on the paper, then the cylinder-piston group is worn out. The degree of wear is determined by compression in the cylinders (see "Compression in the engine cylinders - check").

- If oil mist does not come from the ventilation system, then the cause of increased oil consumption may be wear on the valve stem seals (see "Oil seals - replacement"). In this case, the car will have a smoky exhaust.

Warning! The operation of the engine with a worn cylinder-piston group, faulty valve stem seals or low-quality fuel leads to failure of the catalytic converter and oxygen concentration sensor.