Tip: A spark indicator for fuel-injected engines can be used to quickly check the ignition system. It is put on a spark plug, and a high-voltage wire is connected to it. When checking, you must follow the instructions supplied with the device.

Note: On engine 11183 (1,6i) ignition coil is used. On the engine 2111 (1,5i) ignition coil or ignition module can be installed (see "System description"). The replacement of the ignition coil is shown below. Module replacement is performed in the same way.

You will need a multimeter to do the job (in voltmeter and ohmmeter mode).

Execution sequence

1. We prepare the car for work (see "Preparing the car for maintenance and repair"), turn off the ignition.

2. Having released the latch, disconnect the block of the wiring harness from the coil terminals (module) ignition.

3. Turning on the ignition, use a voltmeter to measure the voltage between terminal 15 and "weight" (for ignition coil) or terminals C and D (for ignition module) wiring harness pads.

Recommendation: The voltage must be at least 12 V. If the voltage is not supplied to the block or it is less than 12 V, then the battery is discharged, the power circuit is faulty or the computer is faulty. You can verify that the ignition module is faulty by replacing it with a known good one. The ignition coil can be checked with an ohmmeter.

Warning! After completing the measurements, turn off the ignition.

4. Disconnect the high voltage wires from the spark plugs (see "High voltage wires - check and replacement").

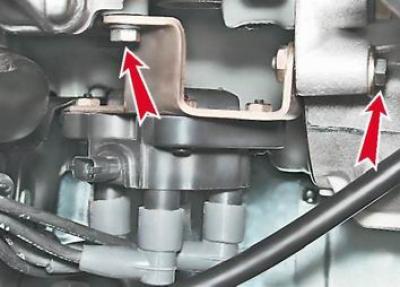

5. socket wrench by 13 mm unscrew the two bolts of the upper mounting of the ignition coil bracket.

6. Key by 17 mm after loosening the lower bolt of the ignition coil bracket, remove the bracket together with the coil.

7. Disconnect the high voltage wires from the coil (module) ignition (see "High voltage wires - check and replacement").

8. Using an ohmmeter, we measure the electrical resistance between the central terminal 15 and the case (bracket). The device should show the absence of a short circuit of the primary winding of the coil to "mass". We sequentially measure the electrical resistance between the central terminal 15 and the extreme terminals - 1a and 1b. The resistance of each of the primary windings of the coil should be about 0.5 ohm.

Note: When measuring small values of electrical resistance (about 1 ohm) it is necessary to take into account the internal resistance of the device, which can be determined by closing the ohmmeter probes.

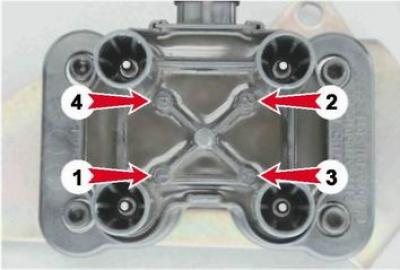

9. Using an ohmmeter, we measure the resistance between the high-voltage terminals of the coil 1 and 4, and then 2 and 3. The resistance of the windings should be about 5.4 kOhm.

Recommendation: A defective ignition coil must be replaced.

10. Hex key by 5 mm unscrew the four screws securing the coil to the bracket and remove the coil.

11. Install the ignition coil in the reverse order of removal. We connect high-voltage wires in accordance with the cylinder numbers printed on each wire and on the coil body next to the terminals.

Tip: Since the numbering of the leads on the coil installed on the engine is not visible, it is better to connect high-voltage wires to the leads of the ignition coil before installing it on the engine.