- multimeter (in voltmeter and ohmmeter mode);

- wire segments.

Removal and inspection

1. We prepare the car for work (see "Preparing the car for maintenance and repair").

2. Having released the latch, disconnect the block of the wiring harness from the canister purge valve.

3. Connect "negative" voltmeter probe to "mass" (to the car body).

4. Turning on the ignition, use a voltmeter to measure the supply voltage at terminal A of the wiring harness block (terminal designations are printed on the block).

Note: The voltage at the output must be at least 12 V. If the voltage is not supplied to the block, or it is less than 12 V, then the battery is discharged, the power circuit is faulty or the computer is faulty.

5. Using a Phillips screwdriver, loosen the clamp that secures the hose to the canister purge valve and remove the hose from the valve nozzle.

Tip: If the hose on the nozzle is tight, and there is a high probability of breaking off the nozzle, then you can remove the valve from the adsorber, and by rotating the valve, remove the hose from it.

6. Prying with a screwdriver, remove the valve from the adsorber.

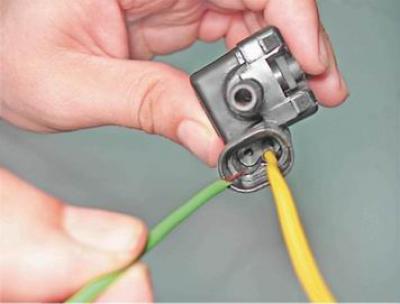

7. We supply 12 V voltage from the battery to the valve terminals ("+" to conclusion A "-" to conclusion B).

Note: When voltage is applied to the terminals, the valve should open with a characteristic click. A defective valve must be replaced.

Installation

If the new valve does not have an o-ring, remove it from the old valve.

Note: A damaged O-ring must be replaced.

Install the valve in the reverse order of removal.