Recommendation: Spark plugs should be replaced every 30,000 km or when they fail if the engine starts to run erratically at idle.

To perform the work, you will need a special socket wrench for spark plugs by 21 mm.

Execution sequence

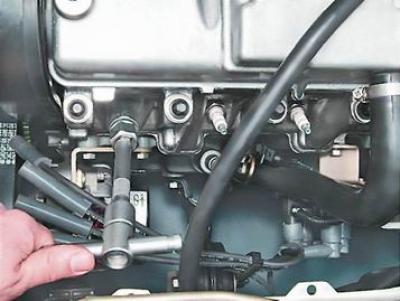

1. Remove the high-voltage wire from the candle of the first cylinder (see above, "High voltage wires - check and replacement").

2. We wipe with a rag and blow compressed air from the tire pump to the installation site of the spark plug (so that grains of sand do not get into the cylinder after removing the spark plug).

3. socket wrench for spark plugs by 21 mm turn off the candle.

Note: The condition of the spark plug can be used to assess the technical condition of the engine and its systems. In a serviceable engine, the spark plug insulator should have a gray or brownish coating. Red or red plaque is caused by the operation of the car on gasoline with a high content of additives. Black oily deposits can be caused by oil entering the combustion chamber. A spark plug with a glow number less than recommended may burn the electrodes. Similar spark plug failures can be caused by a malfunction in the cooling system or the ignition system. The cause of large deposits on the candle may be low-quality gasoline or oil.

4. Before installing the spark plug with a set of round probes, we check the gap between its electrodes. The gap should be 1.0-1.1 mm.

Note: When checking the gap with a flat feeler gauge, the measurement results will be incorrect.

5. We adjust the gap by bending the side electrode.

Warning! To avoid damage to the threads in the cylinder head, the spark plug should first be wrapped by hand, and only then tightened by inserting the wrench into the wrench extension. The moment of an inhaling of a candle is 30-40 Nm.

6. We wrap the candle in the cylinder head and put on it the tip of the high-voltage wires.

7. Similarly, we replace the candles of the remaining cylinders.