In addition, ready-made manual valve holders are on sale.

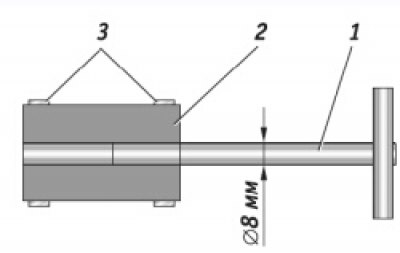

4.14. Device for grinding valves: 1 - metal rod; 2 - rubber hose; 3 - screw clamp

In their absence, you can use a device made according to the drawing (pic. 4.14).

1. Remove the cylinder head (see «Replacing the cylinder head gasket»).

2. Remove the valves from the head and thoroughly clean the valves and seats (see «cylinder head (repair)»).

3. Insert the valve into the block head.

4. Apply a thin layer of lapping paste to the valve face.

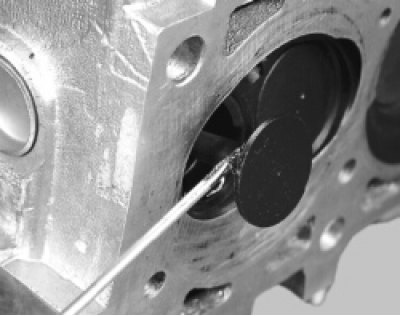

5. Attach the valve stem to the valve lapping tool and use the tool to turn the valve in both directions, periodically pressing the valve against the seat.

6. An external sign of satisfactory grinding is a solid matte gray color of the valve face and seat.

7. After lapping, thoroughly wipe the valve and seat with a clean cloth and rinse to remove any remaining lapping paste. Check the tightness of the valve, for which install it in the head with springs and crackers. Then put the head on its side and pour kerosene into the channel that is closed by the valve. If kerosene does not seep into the combustion chamber within 3 minutes, the valve is tight.