1. Remove the oil pump from the car (see «Removal and installation of the oil pump»).

2. Turn out six bolts of fastening of a cover of the pump.

3. Using two screwdrivers, lift the pump casing until the dowel pins on the casing come out of the holes in the pump cover and remove the pump casing from the cover.

4. Remove the drive from the cover..

5.... and the driven gear of the pump.

6. Turn out a stopper of the reducing valve. Please note: an aluminum sealing ring is installed under the cork. Replace heavily compressed ring.

7. Remove pressure reducing valve spring.

8. Remove the relief valve by gently tapping the body against a clean piece of wood. If the valve does not come out, remove it with a pointed wooden stick.

9. Inspect the aluminum cover. In the contact area of the gears, it should not have noticeable signs of wear, scoring and deep scratches. Otherwise, replace the cover.

10. Inspect the pump housing. On its working surfaces there should be no noticeable signs of wear, scoring and deep scratches. Otherwise, replace the body.

11. Measure the diameter of the driven gear seat on the pump housing. The maximum allowable diameter is 75.1 mm. If the size is larger than specified, replace the housing.

12. Measure the width of the pump casing segment at the middle. If the width is less than 3.4 mm, replace the housing.

13. Measure the thickness of the drive gear. If it is less than 7.42 mm, replace the gear.

14. Measure the thickness of the driven gear. If it is less than 7.35 mm, replace the gear.

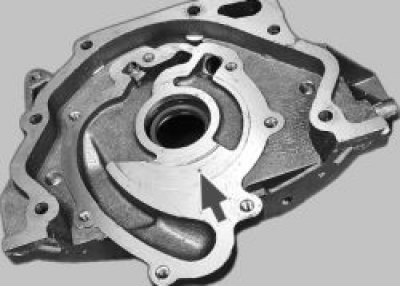

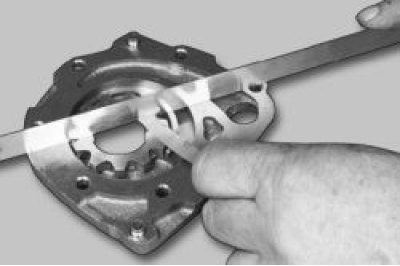

15. Check up axial backlashes of gear wheels. To do this, install the drive gear into the housing, put a metal ruler on the housing and measure the gap between the ruler and the gear with a feeler gauge.

16. In the same way, measure the axial clearance of the driven gear. The maximum allowable axial clearance for the drive gear is 0.12 mm, for the driven gear - 0.15 mm. If clearances are greater than specified, replace gears.

17. More precisely, the axial clearances of the gears can be obtained by calculation. To do this, measure the thickness of the housing along the outer surfaces with a micrometer..

18.... and the thickness of the housing in the area of the socket for the gears in several places (on milled surfaces). Calculate the axial clearance as the difference between the arithmetic mean of the socket depth and the thickness of the gears.

19. Inspect the relief valve seat. There should be no burrs or deep scratches on its inner surface. Otherwise, replace the cover.

20. Replace pressure reducing valve if it has nicks or deep scratches.

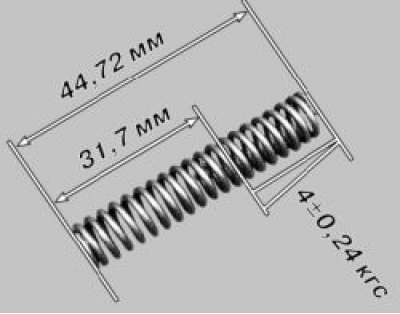

21. Replace bent, broken, or cracked relief valve spring. The height of the spring in the free state should be 44.72 mm, under load (4±0,24) kgf - 31.7 mm. Otherwise, replace the spring.

22. Install the driven gear into the pump housing. The chamfers on the gear teeth must face the housing.

23. Install the drive gear into the pump housing. The chamfers on the gear teeth must face the housing.

24. Install the cover on the body and screw in the bolts of its fastening.

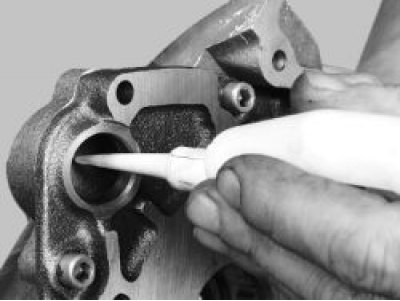

25. Lubricate the pressure reducing valve with engine oil and install it in the socket with the bottom down. Then install the spring and wrap the plug with the o-ring.

26. Fill the pump with engine oil through the oil receiver hole.

27. Rotate the pump gears a few turns to lubricate their running surfaces.