- difficult engine start;

- unstable engine operation;

- engine stalls at idle;

- increased idle speed of the crankshaft;

- the engine does not develop full power;

- jerks and failures in the operation of the engine when the car is moving;

- increased fuel consumption;

- increased content of CO and CH in the exhaust gases;

- glow ignition due to leaky nozzles.

You will need: hexagon «by 5», screwdriver, wrench «at 17».

1. Remove the wire from the terminal «–» battery.

2. Remove the receiver from the inlet pipe (see «Replacing the intake pipe and exhaust manifold gaskets» in subsection «Replacing Engine Seal Parts»).

3. Drain the coolant from the engine cooling system (see «Coolant replacement»).

4. Reduce the pressure in the fuel system (see «Reducing the pressure in the power system» in subsection «Supply system»).

5. Disconnect the injector wiring harness connector.

6. Disconnect the vacuum hose from the fuel pressure regulator.

7. Remove the two screws securing the fuel pressure regulator to the fuel rail..

8.... and take him aside.

Note. If the fuel pressure regulator o-ring remains in the rail, remove it. Replace loose or torn O-ring.

9. Unscrew the nut of the fuel supply pipe..

10.... and disconnect the tube from the fuel rail. Replace loose or torn tube tip O-ring.

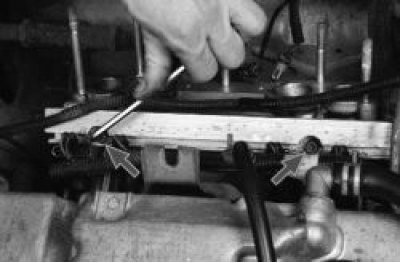

11. Turn out two bolts of fastening of a fuel rail..

12.... remove the bolts together with the washers..

13.... and remove the fuel rail along with the injector wiring harness and injectors.

Warning! If, when removing the fuel rail, any nozzle remains in the engine intake pipe, replace its o-rings and retainer.

14. To check the injectors, connect a fuel pipe to the rail and install a fuel pressure regulator. Connect the injector harness connector.

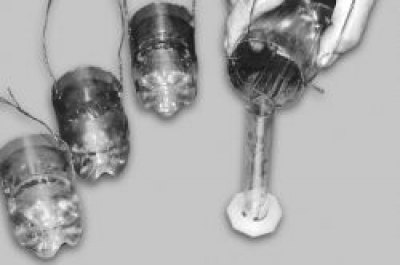

15. Dip the nozzles in transparent containers. The latter are more convenient to hang on the fuel rail. Check the fuel atomization of the injectors. To do this, turn on the starter. The injectors must spray the fuel in the correct cone. Each nozzle should have four jets..

16.... the amount of fuel supplied through the nozzles in all four tanks must be the same (check with measuring container). If any nozzle does not meet these conditions, replace it.

17. Immediately after turning off the ignition, carefully inspect the nozzles. If fuel leakage is noticeable from the atomizer of any injector, then the injector is leaking and must be replaced.

18. If the injector is not spraying fuel, check that it is receiving power. To do this, disconnect the block with wires from it, connect the battery to the nozzle contacts directly and turn on the ignition. If in this case the injector sprays fuel, then there is a malfunction in the electrical circuit of the injector.

19. It is recommended to check the resistance of the injector windings. To do this, disconnect the block with wires from the injector (having previously disconnected the wire from the terminal «–» battery) and connect an ohmmeter to the injector contacts. It should show a resistance of 11-15 ohms. Otherwise, replace the nozzle.

20. Before nozzle replacement reduce the pressure in the supply system (see «Reducing the pressure in the power system»).

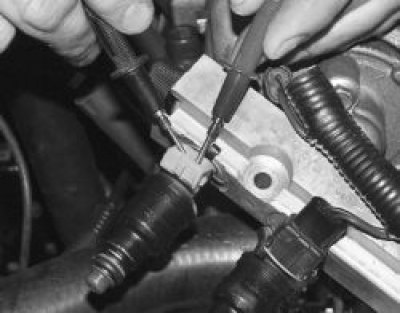

21. Press the spring clip and disconnect the wiring harness block from the injector to be replaced.

22. Slide the nozzle lock to the side..

23.... and remove the nozzle from the fuel rail. Replace the other defective injectors in the same way.

Note. Check the o-rings on all injectors from the side of the ramp..

...and intake pipe. Replace cracked or loose rings.

Helpful advice. We recommend replacing the injector O-rings each time the fuel rail is removed, as in many cases engine malfunction is caused by leaking injector seals.

24. Establish nozzles, a fuel stage in an order, the return to removal. Lubricate the injector o-rings with petrol before installation.

25. To replace the clamps that do not hold the nozzles well, slide them to the recess for the ramp mounting bolt or to the edge of the ramp.