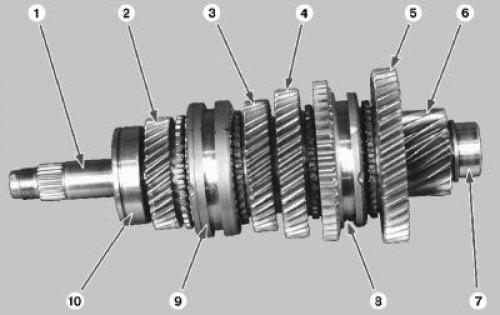

Transmission output shaft: 1 - secondary shaft; 2 - gear IV gear; 3 – gear wheel of III transfer; 4 – gear wheel of the II transfer; 5 - gear wheel of the 1st gear; 6 - main gear drive; 7 - the inner ring of the front shaft bearing; 8 - synchronizer of I and II gears with a gear rim of reverse gear; 9 - synchronizer III and IV gears; 10 - rear shaft bearing

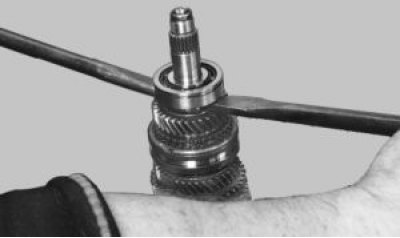

1. Clamp the shaft with light force in a vise with soft metal jaws.

Warning! The output shaft must be clamped in a vice with soft pads on the jaws for the inner ring of the front bearing. Tighten the vise so that the shaft can be tilted by hand, otherwise the bearing race surface may be damaged.

2. Using two mounting blades, compress the output shaft rear bearing.

3. Remove thrust washer…

4.... the driven gear of the IV gear..

5.... IV gear needle bearing and mark it.

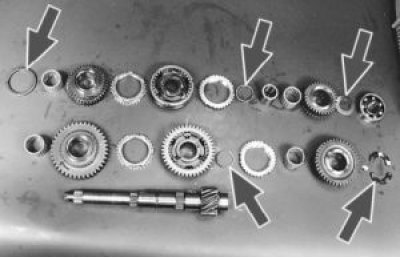

Warning! Be sure to mark the needle bearings and bushings according to the gear number. When assembling, they must be installed in the same places. It is most convenient to insert an appropriate needle bearing into the gear and (where is she) bushing..

... and tie them with rope or wire.

6. Remove spacer ring.

7. Using two mounting blades, slide the synchronizer of III and IV gears through the gear of the III gear from the splines of the shaft.

8. Remove the 4th gear needle bearing bushing.

9. Remove the 3rd and 4th gear synchronizer with the 4th gear blocking ring.

10. Mark the blocking ring with respect to the synchronizer sleeve.

Warnings!

Be sure to mark the locking rings with respect to the coupling. During operation, the teeth of the rings are run in to the teeth of the coupling, therefore, during assembly, it is necessary to install the rings in the same position.

If you do not intend to disassemble the synchronizer, tie it with a rope or wire so that it does not fall apart.

11. Remove the blocking ring of the 3rd gear gear and mark it with respect to the synchronizer clutch.

12. Remove the 3rd gear gear.

13. Remove the 3rd gear needle bearing and mark it.

14. Remove the retaining ring of the thrust half rings..

15.... and two persistent half rings.

16. Remove the locking ball from the hole in the shaft.

17. Remove the 2nd gear gear.

18. Remove the 2nd gear needle bearing and mark it.

19. Remove the circlip.

20. Install the gear shaft of the 1st gear on the vise jaws and, by hitting the wooden mallet on the end of the shaft, press the synchronizer of the 1st and 2nd gears from the splines of the shaft.

21. Remove the synchronizer of I and II transfers with a blocking ring of the II transfer.

Note.

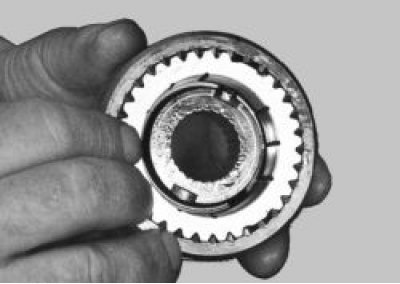

On the synchronizer of I and II gears, a gear rim of the reverse gear is made.

22. Remove the 1st gear blocking ring and mark it with respect to the synchronizer clutch.

23. Remove the 1st gear gear.

24. Remove the circlip.

25. Slightly open the lock of the 1st gear needle bearing and remove the bearing by sliding it along the shaft. Label the bearing.

26. Turn the shaft over and use two large screwdrivers to compress the shaft front bearing inner race. Then remove the thrust washer.

27. Thoroughly clean, rinse and dry the output shaft parts. Examine them carefully.

28. Check the condition of the shafts. In the presence of pitting (shells) bearing journals or wear marks, the shafts must be replaced. Shaft splines must not be dented, scuffed or worn. Replace shafts with defective splines.

29. Check up a condition of gear wheels of a transmission. In the presence of chips, chipping of teeth, scoring in the internal holes and other damage, the gears must be replaced.

30. Check the condition of the bearings. In the presence of pitting (shells) on treadmills and rolling elements, traces of indentation of rolling elements on treadmills, damage to cages, replace bearings.

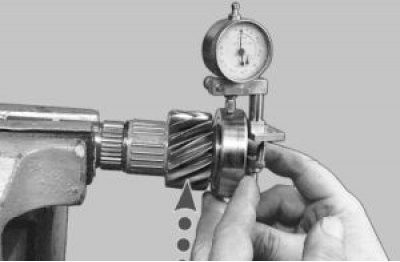

31. The radial clearance of ball and roller bearings should not exceed 0.05 mm. This can be checked with an indicator. Install the bearing on the shaft and the indicator leg on the top of the bearing outer race. Lightly press the bearing from the bottom up. The difference in the indicator readings between the initial position and when the bearing is pressed will be the radial clearance.

32. Check up a condition of blocking rings of synchronizers. If there are nicks and chips on the gear rims or significant wear on the cones, replace the blocking rings.

33. Check up a backlash between gear wheels and blocking rings corresponding to them. The minimum allowable gap is 0.6 mm. If it is less, the blocking ring must be replaced.

Note. When replacing the blocking ring, check the gap between the new ring and the gear. Check the correctness of the conical surface of the ring by putting it on the gear cone and shaking your hand; backlash is not allowed.

34. If scoring and deformation are found on the thrust washers and retaining rings, if the elasticity of the retaining rings is lost, replace them.

35. Collect a secondary shaft in an order, the return to dismantling. Install the old blocking rings in accordance with the previously made marks. Install the new rings so that the small protrusions on the ring (missing teeth) coincided with the grooves of the synchronizer hub where the latches are installed.

36. Press the rear shaft bearing with a suitable mandrel, applying force only to the inner race of the bearing.

37. After assembly, check the operation of the synchronizers. To do this, manually move the synchronizer clutches to the engagement position of the respective gears.