Disassembly

Drain the oil from the steering box. Attach the crankcase to bracket A.74076/R with support A.74076/1.

Having unscrewed the nut of fastening of the steering arm 2 (pic. 5-5) and removing the spring washer, remove the bipod with a puller A.47043 (pic. 5-6). Having unscrewed the fastening bolts, remove the cover 12 (pic. 5-5) steering gear housing together with adjusting screw 8, adjusting plate 9, lock washer 10 and locknut. Remove the shaft 7 of the bipod assembly with the roller from the crankcase 1 of the steering mechanism.

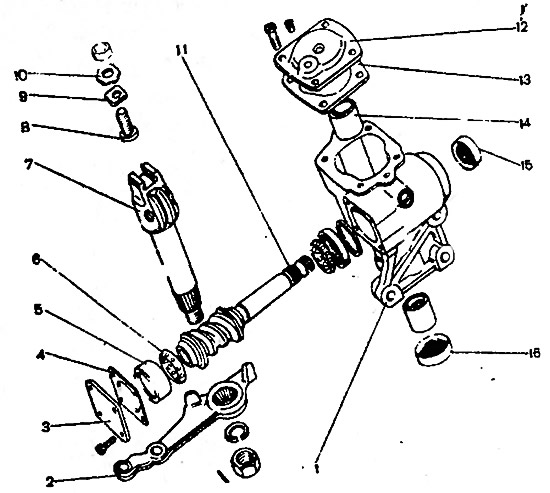

Pic. 5-5. Steering gear details: 1 - crankcase; 2 bipods; 3 - lower crankcase cover; 4 - shims; 5 - the outer ring of the worm shaft bearing; 6 - separator with balls; 7 - bipod shaft; 8 - adjusting lice; 9 - adjusting plate; 10 - lock washer; 11 - worm shaft; 12 - upper crankcase cover; 13 - sealing gasket; 14 - bipod shaft sleeve; 15 - worm shaft seal; 16 - bipod shaft seal

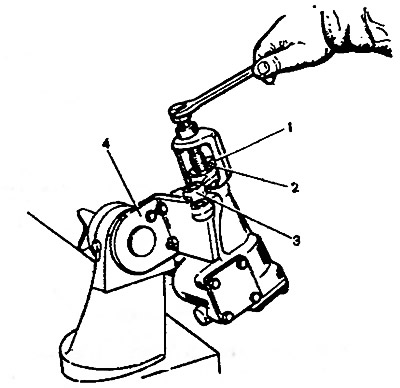

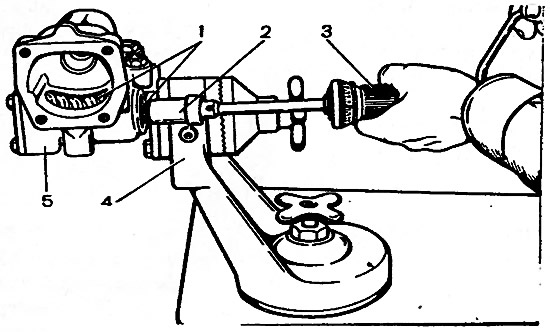

Pic. 5-6. Removing the bipod: 1 - puller A.47043; 2 - a shaft of a bipod of a steering; 3 - bipod; 4 - bracket A.74076/R.

Having unscrewed the fastening bolts, remove the cover 3 of the worm shaft thrust bearing together with the shims 4.

Using the shaft 11 of the worm, push the outer ring 5 of the bearing out of the crankcase and remove the shaft together with the separators 6 of the bearings. Remove the worm shaft seal 15 and the bipod shaft seal 16.

Using mandrel 67.7853.9541, remove the outer ring of the upper bearing (pic. 5-7).

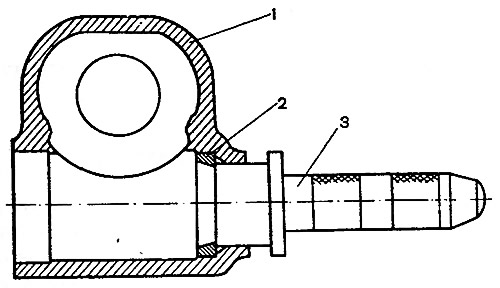

Pic. 5-7. Removing the outer ring of the upper bearing of the worm using a puller 67.7853.9541: 1 - steering gear housing; 2 - the outer ring of the upper bearing of the worm; 3 - mandrel 67.7853.9541

Assembly

Assemble the steering gear on the bracket A.74076/R in the reverse order of disassembly.

Press the outer ring of the upper bearing of the worm with mandrel 67.7853.9541, rearranging the nozzle on the handle of the mandrel with the reverse side.

After installing the worm in the steering gear housing and fixing the bottom cover (pic. 5-8), check with dynamometer 02.7812.9501 and head A.95697/5 (pic. 5-9) moment of friction of the worm shaft; it should be in the range of 19.6-49 N cm (2-5 kgf cm). If the torque is less than specified, reduce the thickness of the shims 2 (pic. 5-8) and if more, increase.

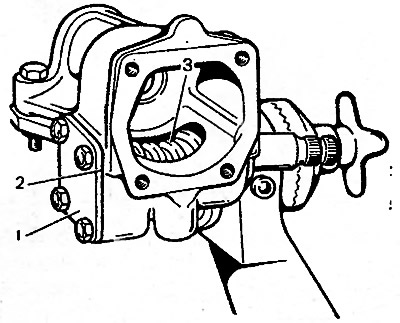

Pic. 5-8. Steering gear worm installation: 1 - bearing cover; 2 - adjusting gasket; 3 - worm

Pic. 5-9. Control of the friction moment of the worm with a dynamometer: 1 - worm. 2 - head A.95697/5; 3 - dynamometer 02.7812.9501; 4 - arm of the stand for repair of the steering gear; 5 - steering gear housing

After installing the bipod shaft, check the absence of play in the engagement of the roller with the worm in the positions of the worm shaft turned to the right and left by 30°from the neutral position of the bipod. Eliminate any gap in the engagement with the adjusting screw 2 (rice. 5-2) and tighten locknut 3.

After adjusting the gap in the engagement of the roller and the worm, check the friction torque of the worm shaft with a dynamometer, which should be equal to 68.6-88.2 N cm (7-9 kgf cm) or (88.2-117.5 Ncm) * when turning the worm shaft by 30 both to the left and to the right from the middle position and should decrease smoothly to 49 N cm (5 kgf cm) or (68.6 Ncm) * when turning from an angle of 30°to the stop.

Upon completion of assembly, check the angles of rotation of the bipod from the neutral position, which should be 32°10'±1°both to the left and to the right until the bipod stops against the bolt heads; pour 0.215 l of transmission oil TAD-17i into the crankcase of the steering mechanism.