Distributor

Attention. Until 1980, ignition distributors of the R-125 V type were used on engines (pic. 7-20). Since 1980, along with the carburetor 2107-1107010-20, ignition distributors of type 30.3706-02 began to be installed (pic. 7-21), having a vacuum ignition timing controller.

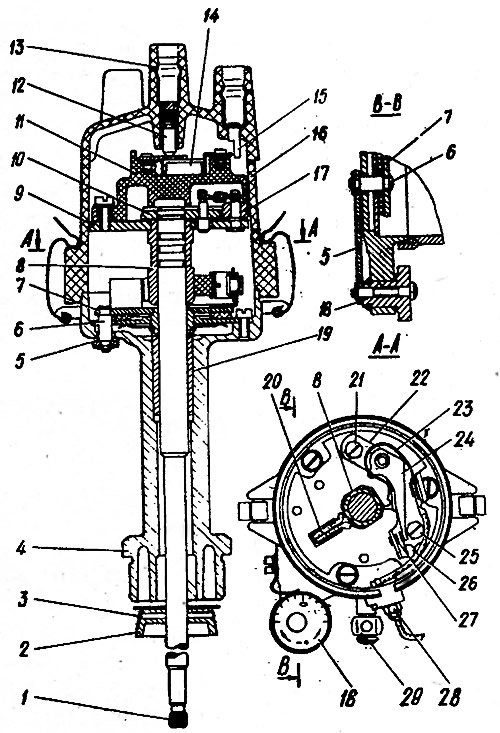

Pic. 7-20. Ignition distributor R-125V: 1 - roller; 2 - oil slinger; 3 - spiral hairpin; 4 - body; 5 - thrust; 6 - axis, 7 - movable breaker plate, 8 - breaker cam; 9 - driven plate; 10 - leading plate; 11 - rotor, 12 - central carbon electrode; 13 - terminal of the central electrode; 14 - resistor; 15 - side electrode; 16 - cover; 17 - weight; 18 - eccentric octane corrector; 19 - roller sleeve; 20 - felt; 21, 25 - screws for fastening the rack with breaker contacts; 22 - rack with breaker contacts; 23 - lever spring; 24 - lever; 26 - groove for adjusting the position of the rack; 27 - breaker contacts; 28 - nut for fastening the low voltage wire tip; 29 - roller oiler

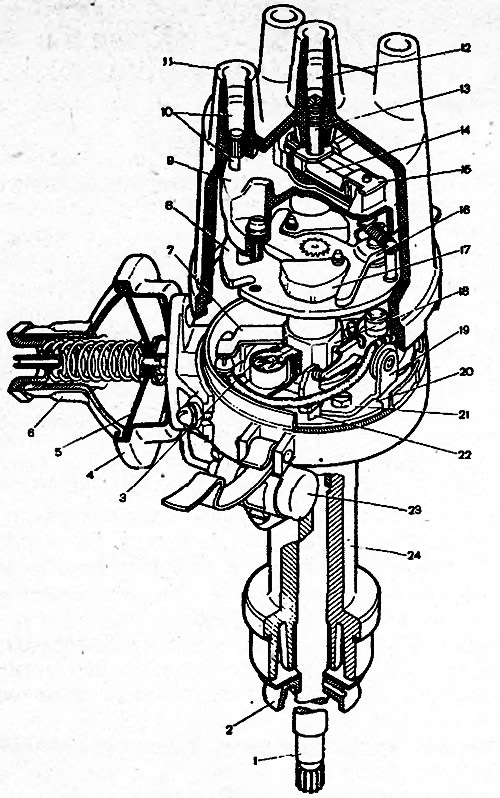

Pic. 7-21. Ignition distributor 30.3706-02: 1 - roller; 2 - oil slinger; 3 - felt; 4 - housing of the vacuum regulator; 5 - membrane; 6 - vacuum regulator cover; 7 - thrust of the vacuum regulator; 8 - base plate of the centrifugal regulator; 9 - ignition distributor rotor; 10 - side electrode with terminal; 11 - cover; 12 - central electrode with terminal; 13 - coal of the central electrode; 14 - resistor; 15 - outer contact of the rotor; 16 - centrifugal regulator plate; 17 - weight; 18 - cam breaker; 19 - contact group: 20 - movable breaker plate; 21 - screw for fastening the contact group; 22 - groove; 23 - capacitor; 24 - ignition distributor housing

Before installing the ignition distributor on the stand, check the condition of the breaker contacts, whether the lever with the moving contact is sticking on the axis and the pressing force of the contacts, which should be 4.9-5.88 N (500-600 gs). Check the wear of the breaker lever pads; in case of wear, adjust the gap between the breaker contacts. If the lever sticks on the axis or its spring is weakened, replace the contact group.

If the breaker contacts are dirty, burnt, or eroded, clean them with a velvet file. Grinding skin and other abrasive materials cannot be used for this purpose.

After stripping, wipe the breaker contacts with chamois soaked in gasoline. Then pull back on the lever to let the gasoline evaporate, and wipe the contacts again with dry chamois leather. Instead of suede, you can use any material that does not leave fibers.

Contacts must be in contact with the entire surface. If this does not happen, then bending the rack bracket, adjust the position of the fixed contact. It is impossible to bend the lever with a movable contact. Wipe off the ignition distributor cap from dirt and oil.

Slightly lifting the cover of the ignition distributor, check if the breaker contacts are open.

Checking work. Mount the distributor on an electrical test bench and connect it to an adjustable speed motor.

Make connections to the ignition coil and to the battery; connect the four terminals of the cover on the stand with spark gaps, the gap between the electrodes of which is adjustable.

Set a gap of 5 mm between the electrodes of the arresters, turn on the electric motor of the stand and rotate the distributor roller for several minutes clockwise at a frequency of 200 min-1. Then increase the gap between the electrodes to 10 mm and watch for internal discharges in the distributor. Internal discharges are detected by sound or by the weakening and interruption of sparking on the arrester of the test bench.

During operation, the ignition distributor should not produce significant noise at any speed of the roller.

Removing the characteristics of automatic ignition advance. Install the distributor on the stand and make electrical connections in accordance with the instructions for the stand. Turn on the electric motor of the stand and rotate the ignition distributor shaft with a frequency of 150-200 * min-1. On the graduated disk, read off the value in degrees, according to which one of the four sparks is obtained.

* 300-400 min-1 for the R-125V ignition distributor.

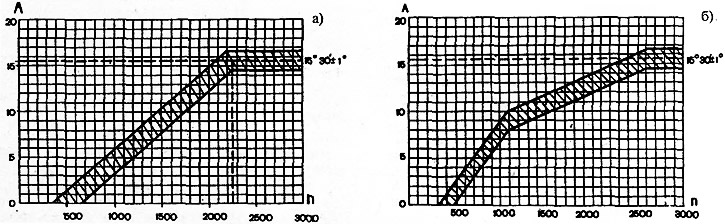

Increasing the rotational speed and making readings at each increase by 200-300 min-1, determine the number of degrees of advance relative to the original value, depending on the frequency of rotation of the distributor shaft. Compare the resulting characteristic with the characteristic in Figure 7-22.

Pic. 7-22. Characteristics of the centrifugal regulator of the ignition distributor: a - ignition distributor R-125V; c - ignition distributor 30.3706-02; A - ignition timing, deg; n - frequency of rotation of the ignition distributor shaft, min-1

Checking the angle of the closed state of the contacts. Turn on the electric motor of the stand and bring the rotational speed of the ignition distributor roller to 1000 min-1.

On the illuminated parts of the scale, measure the angle of the closed state of the contacts, which should be 55±3°.

After checking the angle of the closed state of the contacts, check the angles between the opening moments of the contacts on the cylinders relative to the first (asynchronism), which should not differ from the nominal by more than±1°.

Removal of characteristics of the vacuum regulator. Connect the vacuum regulator of the ignition distributor with the vacuum pump of the stand with a hose. Turn on the electric motor of the stand and rotate the ignition distributor shaft with a frequency of 1000 min-1. On the graduated disk of the stand, set the conditional «zero» by the moment of sparking in any of the cylinders.

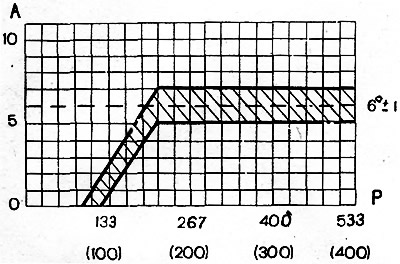

Gradually increasing vacuum, every 26.7 GPa (20 mmHg st) note the number of degrees of ignition advance relative to the original value. Compare the resulting characteristic with the characteristic in Fig. 7-23.

Pic. 7-23. Characteristics of the vacuum regulator of the ignition distributor 30.3706-02: A - ignition timing, deg; R - rarefaction, hPa (mmHg Art.)

Adjust the characteristics of the vacuum regulator by selecting shims between the spring and the plug of the vacuum regulator.

Pay attention to the clearness of the return to its original position of the movable breaker plate after the removal of the vacuum.

Insulation resistance test. Insulation resistance between different terminals and «weight» checked with a megger and must be at least 10 MΩ at (25±5) °C. Resistance between the low voltage terminal of the breaker and «weight» measure with the breaker contacts open.

Capacitor check. Capacitor capacitance, measured in the frequency range between 50 and 1000 Hz, should be in the range of 0.20-0.25 uF.

Ignition coil

To check the health of the ignition coil, the following checks must be made.

Ohmic resistance the primary winding at 20°C should be 3.07-3.5 ohms, and the secondary winding 5400-9200 ohms.

Insulation on «mass». The ignition coil must withstand an alternating current voltage of 1500 V and 50 Hz, supplied for 1 min between one end of the primary winding and the housing, without dropping discharges.

Insulation resistance on «mass» must be greater than or equal to 50 MΩ.

Spark plug

If interruptions in ignition are noticed, especially in one or more cylinders, it is necessary to check the condition of the candles.

Before testing spark plugs with soot or dirty clean on a special installation with a jet of sand and blow with compressed air.

If the soot is light brown in color, then it can not be removed, since it appears on a serviceable engine and does not interfere with the operation of the ignition system.

After cleaning, inspect the candles and adjust the gap between the electrodes. If the insulator has chips, cracks, or the ground electrode welding is damaged, replace the spark plug.

Gap (0.5-0.6mm) between the spark plug electrodes, check with a round wire probe from the tool kit that came with the car. It is impossible to check the gap with a flat probe, since this does not take into account the recess on the side electrode, which is formed during the operation of the candle. Adjust the gap by bending only the side electrode of the spark plug. Do not bend the central electrode, as this can cause breakage of the ceramic insulator.

Leak test. Screw the candle into the appropriate socket on the stand, and then create a pressure of 2 MPa in the stand chamber (20 kgf/cm2).

Drop a few drops of oil or kerosene onto a candle from an oil can; if the tightness is broken, then air bubbles will come out, usually between the insulator and the metal body of the candle.

Electrical test. The gap between the spark plug electrodes is adjusted to 0.6 mm, screw it into the socket on the stand and tighten with a torque wrench to a torque of 30.67-39 Nm (3.13-3.99 kgf·m); tightness is ensured by an elastic gasket of the socket connector. Adjust the gap between the spark gap electrodes to 12 mm, which corresponds to a voltage of 18 kV, and then create a pressure of 0.6 MPa with a pump (6 kgf/cm2).

Place the tip of the high voltage wire on the spark plug and press the switch button.

In this case, the following may be observed:

- 1. In the eyepiece of the stand, a full-fledged spark is noticed between the electrodes of the candle; in this case, the candle is considered excellent.

- 2. Sparking occurs between the electrodes of the spark gap: you should lower the pressure in the device and check at what pressure sparking occurs between the spark plug electrodes. If at a pressure of 0.5 MPa (5 kgf/cm2), then the candle is considered normal, and if at. pressure 0.4 MPa (4 kgf/cm2) and below - defective.

Several sparks are allowed on the spark gap, if there is no sparking on the spark plug and on the spark gap, it must be assumed that there are cracks on the spark plug insulator and that the discharge occurs inside between «weight» and electrodes. Such a candle is considered defective.

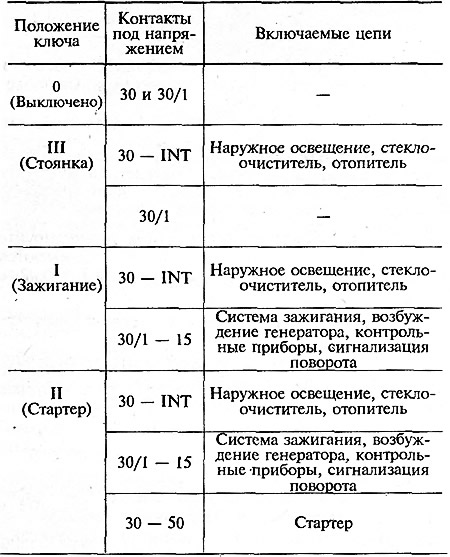

Ignition switch

At the ignition switch, the operation of the anti-theft device is checked and the correct closure of the contacts at various key positions (see table. 7-5). The voltage from the battery and the generator is supplied to the contacts «30» and «30/1» free plug «INT» used to connect the radio.

Table 7-5. Switchable circuits at various key positions

The locking rod of the anti-theft device must extend when the key is set to the position «PARKING» and take it out of the castle. The rod must retract after turning the position key «PARKING» into position «TURNED OFF».

When installing the contact part in the circuit breaker housing, it must be positioned so that the plugs «15» and «30» were on the side of the locking rod (see fig. 7-24), while the wide protrusion of the contact part will fit into the wide groove of the circuit breaker body.

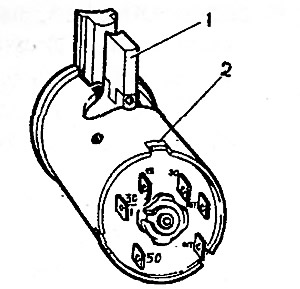

Pic. 7-24. View of the contact part of the ignition switch: 1 - locking rod; 2 - wide protrusion of the contact part

Checking elements for suppression of radio interference

The elements for suppressing radio interference include high-voltage wires with a distributed resistance of 2000±200 Ohm / m and an interference suppression resistor in the rotor of the ignition distributor with a resistance of 5000-6000 Ohm. The performance of these elements is checked with an ohmmeter.