Disassembly

Unscrew the nut on the lower contact bolt of the traction relay and disconnect the stator winding output from it. Turn away nuts of fastening of the traction relay and remove it.

Loosen the screw fastening the tightening protective tape on the cover 10 from the side of the collector and remove the tape 9 with the gasket. Turn out screws of fastening of plugs of brushes and remove brushes. Starter 35.3708 remove the lock washer from the rear end of the shaft.

Loosen the nuts of the tie rods 15 (rice. 7-16), turn out the studs and remove the cover 1 from the drive side together with the armature 16.

Detach the manifold side cover from the housing. Remove the rubber plug 2 of the lever from the cover on the drive side, unpin and remove the axle of the lever 3 of the starter drive, remove the lever and anchor from the cover

To unmoor the drive, remove the circlip from under the stop ring 21 (rice. 7-13). The drive is disassembled after removing the lock washer from the coupling hub.

After disassembly, blow the parts with compressed air and wipe clean.

Checking the technical condition and repair

Anchor. Check with a megaohmmeter or with a lamp powered by 220 V for a short circuit in the armature winding to «mass».

Voltage through the lamp is supplied to the collector plates and to the armature core. The burning of the lamp indicates the short circuit of the winding or collector plate with «weight». When checking, the megger must show a resistance of at least 10 kOhm. Anchor having a short circuit with «weight», replace.

Using a special device, check for short circuits between the armature winding sections or collector plates, and for breaks at the soldering point of the winding section leads to the collector plates.

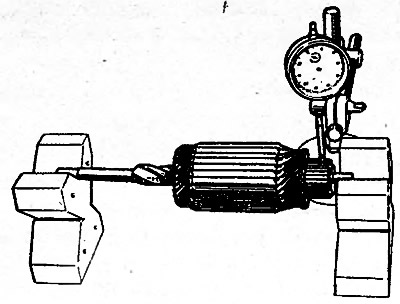

Inspect the working surface of the manifold and check its runout relative to the shaft trunnions (pic. 7-17). Clean the dirty or burnt surface with a fine-grained sandpaper. If the surface damage is significant or the runout is greater than 0.06 mm, turn the manifold on a lathe, removing as little metal as possible. The minimum diameter to which the collector can be machined is 36 mm. After turning, sand the collector with fine-grained sandpaper.

Pic. 7-17. Checking the runout of the collector using an indicator

Check core runout against shaft trunnions. If it is more than 0.08 mm, replace the anchor.

Check the condition of the surfaces of the splines and trunnions of the armature shaft. They should not have scuffs, nicks and wear. If there are yellow marks on the surface of the shaft from the gear bush, remove them with fine-grained sandpaper, as they can cause the gear to seize on the shaft.

Drive unit. Gear teeth should not show significant wear. If there are nicks on the lead-in part of the teeth, then grind them with a fine-grained emery wheel of small diameter. The gear should turn easily relative to the clutch hub, but only in the direction of rotation of the armature when starting the engine. If drive parts are damaged or severely worn, replace the drive with a new one.

Stator. Check with a megger or with a lamp powered by a voltage of 220 V whether there is a short circuit in the winding of the staura to «mass». The voltage through the lamp is supplied to the common terminal of the winding and to the starter housing. If the lamp is on or the megger shows a resistance of less than 10 kΩ. and also if the winding has traces of overheating (insulation blackening), replace the winding.

To replace the stator winding coils, remove the poles by unscrewing the fixing screws with a drill screwdriver. Before removing the poles, make marks on the body and poles in order to put them in their original position after assembly.

It is recommended to preheat the winding to approximately 50°C before installation in order to give it flexibility and facilitate laying on the poles. The poles must be tightened with screws to failure so that the air gap between the armature and the poles is maintained in its original dimensions: 0.38 mm when checked with a probe.

Upon completion of assembly, check the inner diameter between the poles, which should be 67.80-67.97 mm. In addition, use a 67.66 mm plug gauge to check the concentricity of the body and poles. The gauge must freely enter and rotate between the poles when landing on the inner surface of the housing. If this does not happen, then repeat the assembly, as it seems to have been performed incorrectly.

Pole boring is not allowed.

Lids. Check the covers for cracks. If there are, replace the caps with new ones. Check the condition of the cover bushings. If worn, replace cap assemblies or bushings only. New bushings after pressing, expand to 12.015+0,15 mm. To replace the bushing in the cover on the collector side, first remove the plug, and after pressing the bushing, put the plug back in place and drill out at three points.

Check the reliability of the fastening of the brush holders on the cover from the side of the collector. Brush holders of positive brushes must not have a short circuit with «weight». The brushes must move freely in the grooves of the brush holders. Replace brushes worn in height up to 12 mm with new ones, after rubbing them against the collector.

Check the spring pressure on the brushes with a dynamometer, which for new brushes should be 9.8±0.98 N (1±0.1 kgf) and, if necessary, replace the springs with new ones.

Traction relay. Check the ease of movement of the relay armature. Check with an ohmmeter whether the contact bolts of the relay are closed by the contact plate. If the contact bolts do not close, then disassemble the relay and clean the contact bolts with fine-grained sandpaper or a flat velvet file. In case of significant damage to the contact bolts at the point of contact with the contact plate, you can turn them by 180°.

Assembly

Lubricate with engine oil before assembly (M-10GI) screw splines of the armature shaft and overrunning clutch hub. Lubricate the bushings of both covers and the gear with engine oil, and the drive ring with LITOL-24 grease.

Before assembling, check the axial free play of the armature shaft by first assembling the covers, body and armature and tightening the nuts of the tie rods. In this case, the armature can be without a drive, and the cover 1 (rice. 7-16) without a lever. The axial free play of the shaft should be within 0.07-0.7 mm. Changing the amount of free play is achieved by selecting the number or thickness of shims 20. For starter 35.3708, shims are located on both sides of cover 10 on the collector side, and the free play of the shaft should be no more than 0.5 mm.

Having picked up the shims, proceed with the assembly, which is performed in the reverse order of disassembly. After assembly, check the starter on the stand.