The car is equipped with a four-speed manual gearbox, with constant meshing of gears, with synchronizers and manual control.

The gearbox has four forward gears (gear ratios: I - 3.242; II - 1.989; III - 1.289; IV - 1,000) and one reverse gear (reverse gear ratio 3.34). The gears of all gears, except reverse, are helical, which reduces noise during operation of the gearbox, and have constant meshing. Reverse gears are spur gears. Gear shifting for forward movement is carried out with the help of synchronizers, and for reverse movement - by moving the intermediate reverse gear. Gear shifting is performed using a lever located on the gearbox housing.

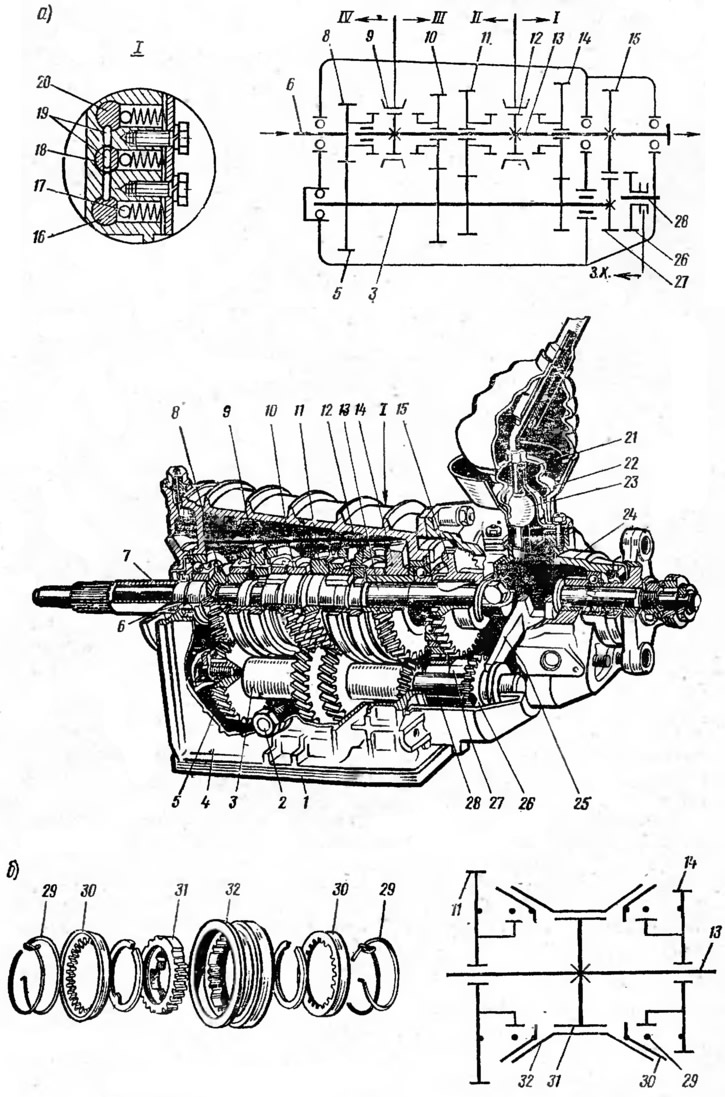

Pic. 28. Gearbox:

a - box assembly; b - synchronizer:

1 - bottom cover; 2 - plug for checking the oil level; 3 - intermediate shaft; 4 - crankcase; 5 - gear wheel of constant engagement of the intermediate shaft; 6 - input shaft; 7 - front cover; 8 - gear of constant engagement of the input shaft; 9 - synchronizer III and IV gears; 10 - third gear gear; 11 - gear 2nd gear; 12 - synchronizer of I and II gears; 13 - secondary shaft; 14 - gear 1st gear; 15 - reverse gear; 16 - slider for the reverse fork; 17 - ball retainer; 18 - slider of the fork of inclusion of III and IV gears; 19 - blocking lock; 20 - slider for the inclusion of I and II gears; 21 - spring; 22 - ball bearing cover; 23 - gear lever; 24 - back cover; 25 - reverse fork; 26 - intermediate reverse gear; 27 - reverse gear of the intermediate shaft; 28 - axis of the intermediate reverse gear; 29 - spring; 30 - blocking ring; 31 - hub; 32 - clutch.

There are 4 gearboxes in the crankcase (pic. 28) on bearings mounted primary (leading) 6, secondary (slave) 13 and intermediate 3 shafts. The input shaft is made as one piece with the gear 8, which is in constant engagement with the gear 5 of the intermediate shaft 3, which is a block of gears. Gears 10, 11 and 14, respectively, III, II and I gears are freely installed on the secondary shaft, which are in constant engagement with the corresponding gears of the intermediate shaft. Synchronizer hubs 9 and 12 and reverse gear 15 are also rigidly fixed on the secondary shaft. The intermediate reverse gear 26 is freely mounted on the axis 28. When I and II gears are engaged, the synchronizer 12 connects the gears 11 and 14, respectively, with the output shaft of the gearbox. When turning on the III and IV gears, the synchronizer 9 connects the gear 10 and the input shaft 6, respectively, with the secondary shaft. The reverse gear is engaged by engaging gear 26 with gears 27 and 15.

Synchronizer Designed for quiet and bumpless shifting. The synchronizer facilitates the work of the driver and increases the life of the gears of the gearbox. It includes: a hub 31, a sliding sleeve 32, blocking rings 30 and springs 29. The synchronizer hub is fixed to the secondary shaft of the gearbox. It has external slots on which a sliding sleeve 32 with internal conical surfaces is installed. The blocking rings 30 have external tapered surfaces and internal bevelled teeth. The blocking rings are constantly pressed by springs 29 to the sliding clutch 32.

The operation of the synchronizer is based on the use of friction forces. Engaging the gear is possible only after preliminary equalization of the angular velocities of the secondary shaft and the gear of the gear being engaged. After equalizing the angular velocities due to friction between the conical surfaces of the sliding clutch 32 and the blocking ring 30, the teeth of the clutch engage with the ring gear of the synchronizer made on the gear. In this case, a freely rotating gear on the secondary shaft is connected to the secondary shaft using a synchronizer, and the gear is engaged.

The gearshift mechanism includes: a shift lever 23, sliders 16, 18 and 20 with forks, ball retainers 17 and a lock 19. The lever 18 is pressed by a spring 21 against the spherical surface of the cover 22 of the ball bearing and has a figured end, which, when shifting gears, enters into fork holes. The forks mounted on the sliders are included in the undercuts of the sliding sleeves of the synchronizers 9 and 12 and the intermediate gear 26 of the reverse gear. Ball locks 17 hold the sliders in the neutral and engaged positions, and the lock 19 prevents the simultaneous inclusion of two gears. The lock consists of two blocking crackers and a pin between them. When moving the middle slider 18, both crackers come out of its recesses and lock the extreme sliders 16 and 20, excluding their displacement. When one of the extreme sliders is moved, the biscuit comes out of its recess, blocks the middle slider, and, acting through the pin on the other biscuit, also locks the other extreme slider.