Check the chain extractor on tool 67.7824.9521 (pic. 2-58), having two stepped rollers 1, on which the chain is put on. Using a counterweight 3, the chain is stretched with a force of 294 N (30 kgf) or 147 N (15 kgf). The adjusting nut 2 ensures that the axis of the counterweight is parallel to the base of the device.

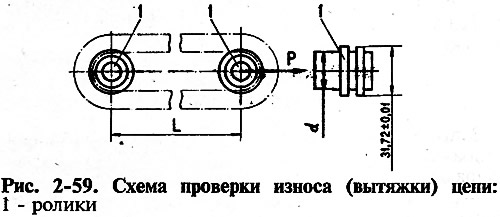

Stretch the chain with a force of 294 N (30 kgf), placing the counterweight in the extreme right position, then reduce the force by 147 N (15 kgf), by moving the counterweight to the extreme left position. Repeat both operations again and determine the chain extension by the distance L (pic. 2-59) between the axes of the rollers By measuring the distance between the diameters d of the rollers with a caliper and adding the diameter d to it, you get the distance L between the axes of the rollers.

For a new chain, the distance L between the axes of the rollers is 495.3+0,5+0,1 mm; if the chain is extended to 499.5 mm, it should be replaced. Before installing on the engine, lubricate the chain with engine oil.