Check with a set of feelers the gaps between the teeth of the gears, as well as between the outer diameters of the gears and the walls of the pump casing (rice, 2-70), which should be respectively 0.15 mm (maximum allowable 0.25 mm) and 0.11-0.18 mm (maximum allowable 0.25 mm) If the clearances exceed the limits, then replace the gears, and if necessary, the pump housing.

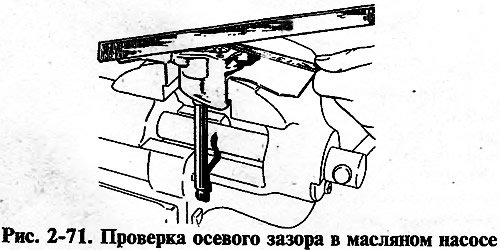

Feeler and ruler (pic. 2-71) check the gap between the ends of the gears and the plane of the housing, which should be equal to 0.066-0.161 mm (maximum allowable 0.2 mm). If the clearance is greater than 0.2 mm, replace the gears or pump housing, whichever is worn. After measuring the details, determine the gap between the driven gear and its axis, which should be 0.017-0.057 (maximum allowable 0.1 we), as well as between the pump shaft and the hole in the housing, this gap should be 0 016-0.055 (maximum allowable 0.1 mm). If the clearances exceed the limits, replace the worn parts.