Disassembly

Flush the transfer case and drain the oil.

Mount the transfer case on a stand for dismantling and loosen the nuts securing the flanges on the drive shaft and on the drive shafts of the front and rear axles.

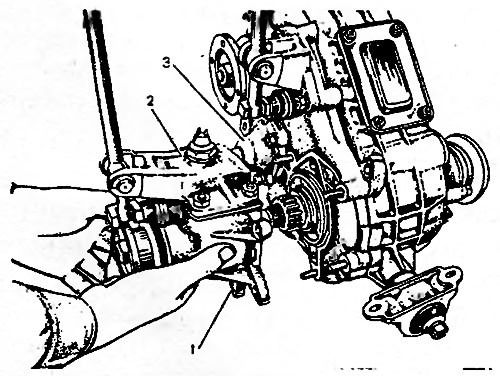

Loosen the fastening nuts and remove the crankcase 1 (pic. 3-42) front axle drive assembly with cover 2, lever, fork, differential lock clutch and front axle drive shaft. Remove housing 3 of the speedometer drive assembly with the driven gear of the speedometer drive.

Pic. 3-42. Removing the front axle drive housing: 1 - front axle drive housing; 2 - crankcase cover; 3 - speedometer drive housing

Removing the lock washer 8 (rice. 3-39) take out an axis 10 and remove the lever 11 of blocking of differential. Then remove the cover 7 of the front axle drive housing and remove the spring and retainer ball 19. Unscrew the locking bolt 3 of the fork 1 of the differential lock and remove the stem 6, the fork 1 and the clutch 2 of the lock.

Remove the rear cover 31 (rice. 3-38) assembled with the rear axle drive shaft, being careful not to damage the gasket. Then remove flanges 12 from the drive shaft and drive shafts of the front and rear axles.

Remove the adjusting rings of the bearings of the drive shafts of the front and rear axles. Remove shaft 11 (rice. 3-38) front axle drive from the crankcase together with bearing 8, thrust ring and oil deflector 9. Remove the rear axle drive shaft from the rear cover 31 together with bearing 36, thrust ring and oil deflector.

Remove the cover 21 of the front bearing of the input shaft and the inspection hatch cover.

Remove bracket 13 (rice. 3-39) gear lever assembly with lever. Then, having removed the lock washer, remove the axle and remove the lever 14.

Unscrew the locking bolt of the shift fork 17 and carefully, closing the lock socket with your finger, remove the stem 12 and the lock parts.

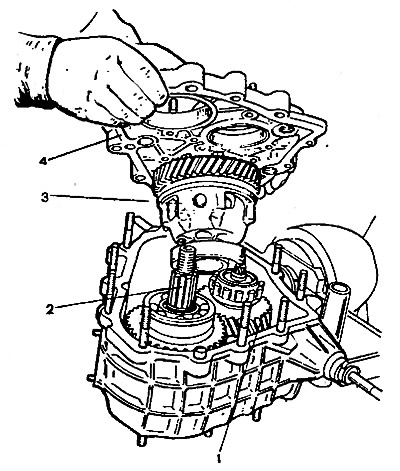

Remove front cover 4 (pic. 3-43) together with the differential, then the differential bearing adjusting ring and remove the bearing assembly with the differential from the front cover.

Pic. 3-43. Removing the transfer box front cover: 1- intermediate shaft; 2 - drive shaft; 3 - differential; 4 - front cover

Remove the adjusting rings from the rear bearings of the drive and intermediate shafts and remove both drive and intermediate shafts from the transfer case housing.

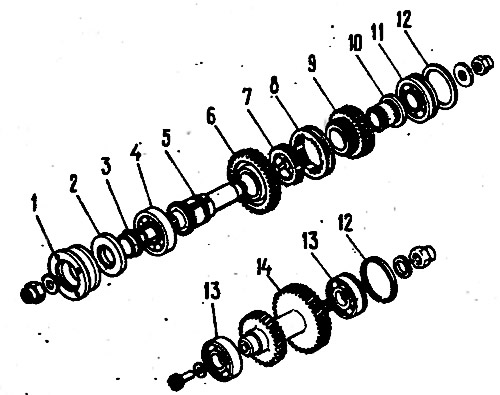

Clamping the drive shaft in a vise, remove the thrust ring and rear bearing 11 (pic. 3-44), using a universal puller. Remove low gear 9 with bushing 10, gearshift clutch 8, clutch hub 7, high gear 6 from the drive shaft.

Pic. 3-44. Details of the drive and intermediate shafts: 1 - flange; 2 - stuffing box; 3 - bearing thrust ring, 4 - front bearing; 5 - drive shaft; 6 - gear of the highest gear; 7 - hub; 8 - clutch; 9 - low gear; 10 - sleeve: 11 - rear bearing; 12 - bearing adjusting ring; 13 - intermediate shaft bearing; 14 - intermediate shaft

Disassemble the differential, for which:

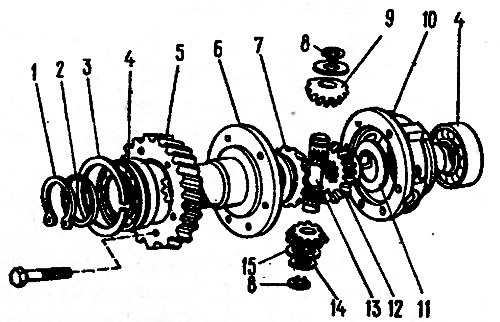

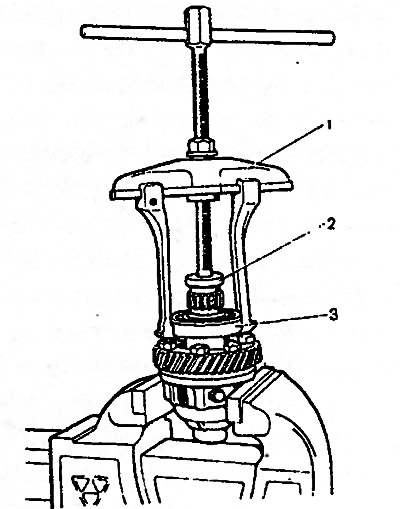

- remove retaining ring 1 (pic. 3-45) and spring washer 2 front bearing;

- remove the rear and front bearings from the differential case (pic. 3-46), using a universal puller and stop 67.7853.9559;

- having unscrewed the bolts of the differential housing, disconnect the housing;

- remove the differential driven gear;

- remove retaining rings 8 (pic. 3-45) and spring washer 14, then press out the axis of the satellites and remove the satellites and gears of the drive axles with support washers.

Pic. 3-45. Transfer Case Differential Details: 1 - retaining ring; 2 - spring washer; 3 - bearing mounting ring; 4 - differential housing bearings; 5 - driven gear; 6 - front differential housing; 7 - front axle drive gear; 8 - retaining ring of the axis of the satellites; 9 - satellite; 10 - rear differential case; 11, 15 - support washer; 12 - rear axle drive gear; 13 - axis of the satellites; 14 - spring washer

Pic. 3-46. Pressing the bearing from the differential housing: 1 - puller А.40005/1/6; 2 - emphasis 67.7853.9559; 3 - bearing

Press out worn or damaged oil seals from the front axle drive housing, from the front bearing cap, and from the rear cap. Remove the nuts from the axles of the suspension cushions and remove the brackets as an assembly.

The assembly of the transfer case is carried out in the reverse order of disassembly, taking into account the following:

- the axial clearance of each axle drive gear should be 0-0.10 mm, and the moment of resistance to rotation of the gears should not exceed 14.7 Nm (1.5 kgf·m). With increased clearance, replace the support washers with others of greater thickness; if the specified clearance cannot be obtained when installing the support washers of the greatest thickness, replace the gears with new ones due to their excessive wear;

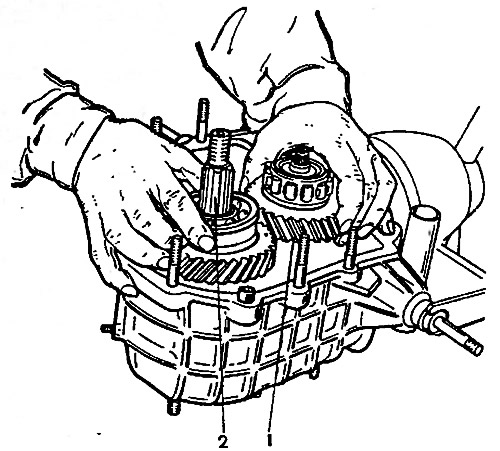

- drive and intermediate shafts are installed in the transfer case at the same time (see fig. 3-47);

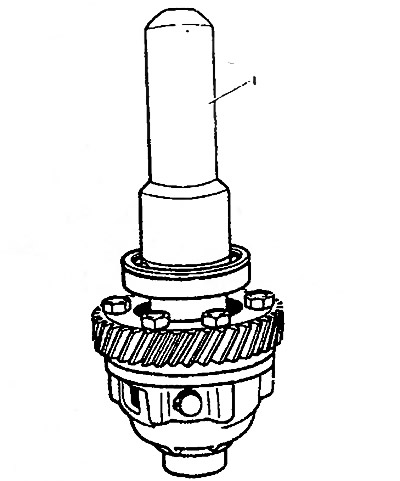

- press the bearings onto the differential housing with a mandrel 67.7853.9558 (see fig. 3-48);

- lubricate the working surfaces of the seals with LITOL-24 grease before installation in the covers and crankcases;

- tighten threaded connections with the moments specified in Appendix 2;

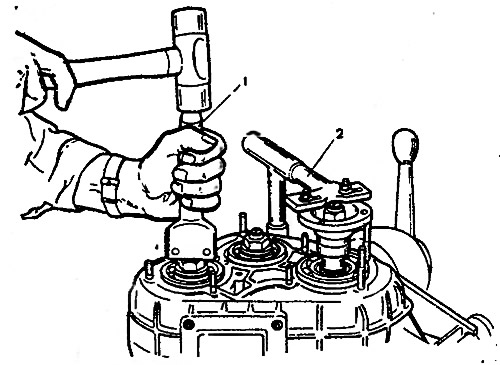

- when crimping the nuts of the transfer box shafts, use the mandrel 67.7820.9520 (see fig. 3-49).

Pic. 3-47. Installation in the crankcase of the drive and intermediate shafts: 1 - intermediate shaft; 2 - drive shaft

Pic. 3-48. Pressing the bearing onto the differential housing: 1 - mandrel 67.7853.9558

Pic. 3-49. Compression of a nut of fastening of a flange of a shaft of a drive of the back bridge: 1 - mandrel 67.7820.9520; 2 - flange retainer

After assembly, fill the transfer case with oil up to the lower edge of the filler hole.