Removing

Place the vehicle over a pit or on a lift. Release the parking brake lever and place the transfer case and transmission shift levers in the neutral position. Remove facing of an upholstery of a casing of a floor, a cover of hatches of levers and handles from levers.

Disconnect the speedometer drive flexible shaft from the transfer case and the wires from the differential lock warning light sensor. Turning the cardan vases, disconnect the flanges of the cardan shafts from the shafts of the transfer case.

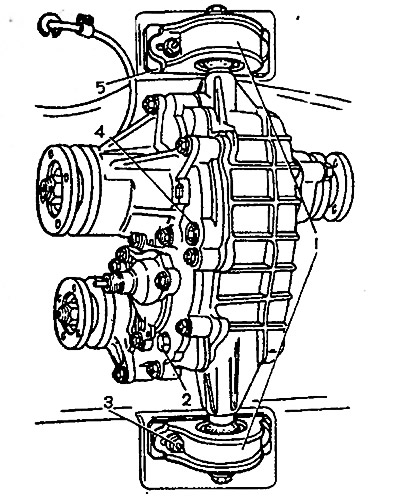

Loosen nuts 3 (pic. 3-40) bolts of fastening of brackets 1 suspension (supports) transfer box and remove it together with the brackets and gaskets 5, which are installed under the brackets. Mark each gasket so that you can put them in place in the same number.

Pic. 3-40. Mounting the transfer case on the car: 1 - transfer box suspension bracket; 2 - filler plug; 3 - nut for fastening the suspension bracket; 4 - drain plug; 5 - shims

Installation and centering

Install and center the transfer case in the following order:

- make sure the engine mounts are properly installed in the brackets (the centering washers of the front engine mounts must fit into the corresponding holes in the side brackets);

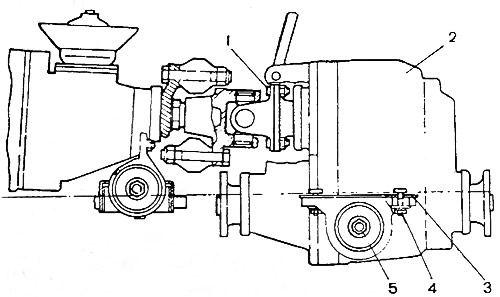

- install the transfer box on the car without fully tightening nuts 4 and 5 (pic. 3-41) mounting brackets for the transfer box suspension;

- moving the transfer case along and across the body, as well as in the vertical direction, find its position in which the flanges of the transfer case input shaft and the intermediate shaft of the driveline will be at the same level, parallel and the gap between them is minimal; in this case, the shafts of the transfer case must be parallel to the bottom of the body;

- by installing previously removed shims under the suspension brackets (supports), fully tighten the nuts securing the transfer box suspension brackets;

- attach the front and rear cardan shafts to the transfer case shafts; connect the flexible shaft to the speedometer drive, and the wires to the differential lock warning light sensor.

Pic. 3-41. Transfer box installation diagram: 1 - bolts for fastening the flanges of the intermediate cardan shaft and the drive shaft of the transfer case; 2 - transfer box; 3 - shims; 4 - nuts for fastening the transfer case to the body; 5 - nuts for fastening the transfer box suspension brackets on the axles

When replacing a transfer case or changing a four-speed gearbox to a five-speed one and vice versa, as well as when «draft» the rear engine mount, which caused the transfer case to vibrate, it is necessary to select and install a new thickness of the pad 5 (see fig. 3-40).

The procedure for selecting shims is as follows:

- make sure the engine mounts are properly installed in the brackets (see chapter «Removal and installation of the engine»);

- disconnect the flanges of the transfer case input shaft and the intermediate shaft of the driveline;

- loosen the nuts securing the transfer case supports to the body, remove the shims and, moving the transfer case along and across the body, as well as in the vertical direction, find its position in which the disconnected flanges will be at the same level, parallel and the gap between them is minimal, and the shafts of the transfer case are parallel to the bottom of the body;

- the resulting gap between the floor of the body and the supports fill with the required number of gaskets,

- align the centering belts of the flanges without creating an interference in the transfer case and engine supports and, holding the transfer case in this position, tighten the previously loosened nuts of the transfer case supports;

- insert and fasten the bolts for fastening the flanges of the transfer case and the intermediate shaft; if the bolts pass freely into the holes of the flanges, then the alignment is carried out correctly, otherwise repeat the operations to align the flanges.