Ball joints

Make sure that the dirt-proof covers of the ball joints are intact; breaks, cracks, delamination of rubber from metal fittings, traces of lubricant leakage are unacceptable.

Check for wear on the running surfaces of the ball joints by manually turning the ball pin. Free movement of the finger or its sticking is unacceptable.

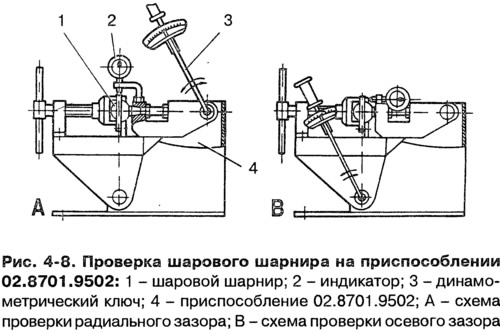

A more accurate check of the condition of the ball joint by the value of the radial and axial clearance is carried out on fixture 02.8701.9502. To do this, install the ball joint 1 (pic. 4-8, A) into the socket of the fixture and tighten it with a screw. Install indicator 2 in the fixture bracket so that the indicator leg rests against the side surface of the hinge body, and the indicator needle is at zero.

Install the torque wrench 3 in the upper socket of the tool and apply a torque of 196 Nm to it (20 kgf·m) in both directions, use indicator 2 to determine the total radial clearance in the ball joint. If it exceeds 0.7 mm, replace the hinge with a new one.

Similarly, check the axial clearance in the ball joint, after changing its mounting in the fixture, as shown in fig. 4-8, B. The axial clearance in the hinge is allowed no more than 0.7 mm.

Suspension springs

Carefully inspect the springs. If deformations are found that may cause a malfunction, replace the springs with new ones.

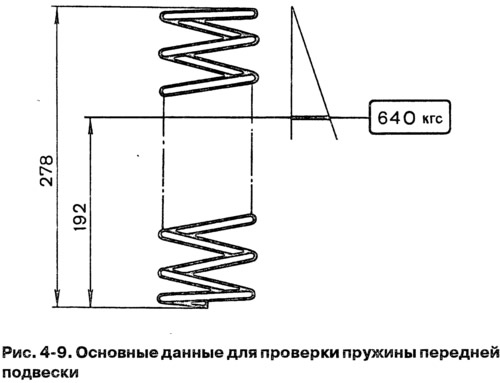

To check the settlement of the spring, squeeze it three times until the coils touch. Compress the spring along the axis of the spring; the bearing surfaces must correspond to the surfaces of the bearing cups on the vehicle suspension. Then apply a load of 6276 N to the spring (640 kgf). Along the length of the spring (pic. 4-9) under the specified load are divided into two classes: class «A» - length over 192 mm and class «IN» - length equal to or less than 192 mm. Springs class «A» may be unmarked or marked with white paint on the outer side of the coils, class springs «IN» marked with black paint.

Install springs of the same class on the front suspension as installed on the rear suspension. In exceptional cases, when springs of class «IN», and there is no such class of springs for the front suspension, then it is allowed to install springs of the class «A». But it is not allowed to install class springs on the front suspension «IN», if the rear suspension is equipped with class springs «A».

Check the technical condition of the insulating gaskets and replace them if they are damaged.

Stabilizer, suspension arms, steering knuckle

Check if the rod is deformed and if its ends are in the same plane; if the deformation is insignificant, then straighten the bar; in case of significant deformation, replace the rod.

Carefully inspect and make sure that the suspension arms, cross member and steering knuckles are not deformed or cracked. If there are cracks or deformations, replace the indicated parts.

Suspension cross member

Rolling pin 67.8732.9501 check the geometric parameters of the crossbar. If the cross member is significantly deformed, when it is impossible to adjust the angles of the front wheels with washers, and if all other suspension elements are in a satisfactory condition, replace the cross member.

Rubber-metal hinges

Signs of the need to replace rubber-metal joints are described in the chapter «Determining the condition of the front suspension parts».