This chapter provides a brief description of the diagnostics of fuel and electrical equipment, the procedure for removing and installing the engine, and also provides features for repairing engine systems.

The device, repair and diagnostics of all engine systems using special instruments and diagnostic cards are described in detail in the Engine Repair Manual of the company «PEUGEOT».

The operation of a diesel engine largely depends on the health of the fuel injection system, so this section focuses on fuel equipment.

In the event of a malfunction in the injection system, do not immediately blame the high pressure pump, but first check:

- condition and filling of the fuel tank;

- supply and discharge fuel lines;

- fuel filter;

- serviceability of injectors;

- the condition of the glow plugs;

- engine stop solenoid valve resistance.

It is also necessary to check the general condition of the engine, since the achievement of a high ignition temperature of the injected fuel depends on the compression, the condition of the valves, the piston rings.

Also check the condition of the air filter, battery, starter, oil level.

Main malfunctions and methods of elimination

1. The engine does not start without emitting smoke:

- check the presence of fuel in the tank;

- set the manual engine stop to. normal position;

- check the fuel supply pipes, in case of a leak, eliminate it by tightening the connections or replace the pipes;

- check the engine stop solenoid valve for continuity in the electrical wiring and fuel flow, and its resistance.

If after these checks and troubleshooting the engine does not start, then remove the high pressure pump and check it on special equipment.

2. Engine does not start with black smoke:

- if the crankshaft speed is less than 150 rpm, then check the condition and tightness of the terminals on the battery (battery) and starter, battery charging, grade and oil level;

- if the crankshaft speed exceeds 150 rpm, then start the engine without the air filter, if the smoke is gone, then replace the filter element, check the correct installation of the air filter housing;

- check the correctness of the injection advance setting, the serviceability of the injectors;

- check the valve adjustment, compression in the cylinders.

If, after all troubleshooting, smoke remains, then remove and check the pump on special equipment.

3. Engine won't start with white smoke (cold engine):

- check glow plugs;

- check the secondary heating system;

- check the condition of the head gasket;

- check injection timing.

If smoke remains after repair work, remove the pump for inspection.

4. Cold engine hard to start with black smoke:

- check glow plugs;

- check the fast idle thermostat;

- check injection advance adjustment;

- check the condition of the injectors;

- check hydraulic tappets and valve clearances;

- check compression.

If after the repair the smoke remains, then remove and check the pump on special equipment.

5. Engine starts and stops:

- check idle adjustment;

- check the type and level of oil;

- check the ventilation system;

- check the fuel supply system;.

- check the condition of the solenoid valve;

- check the secondary heating system;

- check the condition of the air filter;

- check on the LUCAS pump check the condition of the check valve.

If after repair work the engine stalls, then remove the fuel pump.

6. Unstable idle:

- check the adjustment of the limiting system to prevent spontaneous engine stop and idling (for LUCAS);

- check idle adjustment and residual fuel leakage (for Bosch);

- check the condition of the accelerator lever spring;

- check the condition of the fuel supply system;

- check the condition of the injectors;

- check valve clearances;

- check the camshaft belt tension.

If it is not possible to adjust the idle speed, then remove and check the pump on a special stand.

Removal and installation of the engine

Put the car on a lift or over a viewing hole, set the stops under the front wheels and hang the rear axle on one or both sides.

Remove the hood, disconnect the wires from the battery and from the electrical components installed on the engine. Remove the battery and engine compartment lamp.

Drain the liquid from the cooling system and the heater, for which remove the plug from the expansion tank, unscrew the drain plugs on the radiator (bottom left) and on the cylinder block (From the left side).

Disconnect from engine (pic. 9-25) coolant inlet and outlet hoses and remove the radiator assembly with the frame and the electric fan casing. Disconnect the coolant hoses from the thermostat. Disconnect the hoses going to the heater from the engine.

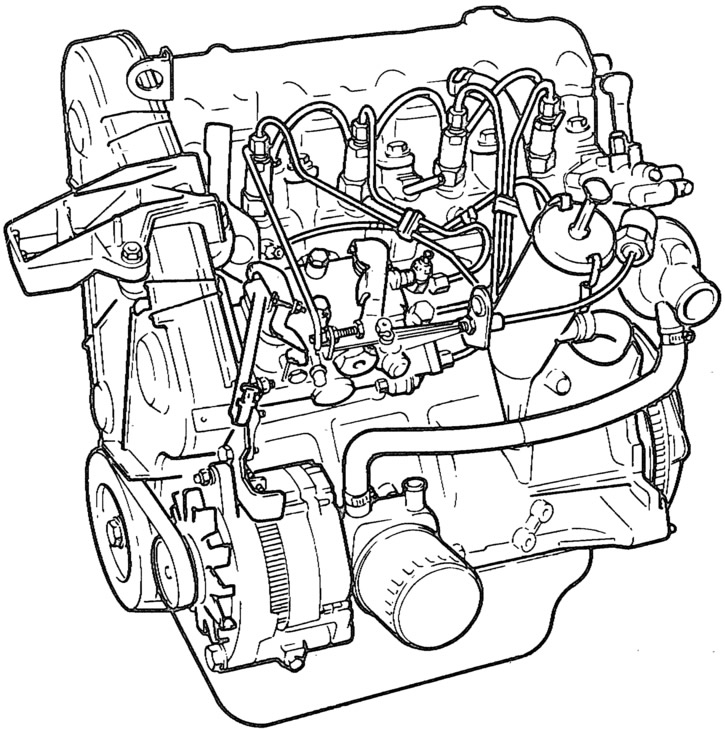

Pic. 9-25. Appearance of the DHW engine (XUD-9SD).

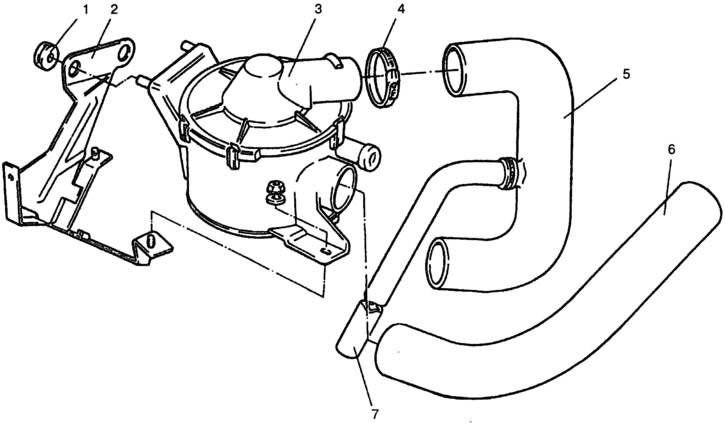

Disconnect from the air filter (pic. 9-26) crankcase ventilation hose, unscrew the three fastening nuts, remove the air filter cover with gasket and remove the filter element. Remove the air filter housing with gasket by unscrewing the four nuts securing it to the intake pipe.

Pic. 9-26. Air filter:

1 - rubber support; 2 - filter mounting bracket; 3 - filter; 4 - clamp; 5 - air duct; 6 - cold air intake; 7 - crankcase ventilation hose.

Disconnect the fuel inlet and outlet hoses from the high pressure fuel pump.

Use a wrench to unscrew the nuts securing the exhaust pipe of the mufflers to the exhaust manifold.

Disconnect the fuel supply cable from the high pressure pump by depressing the ball end with a flat screwdriver.

Disconnect from the lever for setting the fuel injection advance angle (WABT) cable by unscrewing the fastening screw and wringing out the tip.

Remove the gearbox, proceeding as described in chapter «Transmission» Repair manuals.

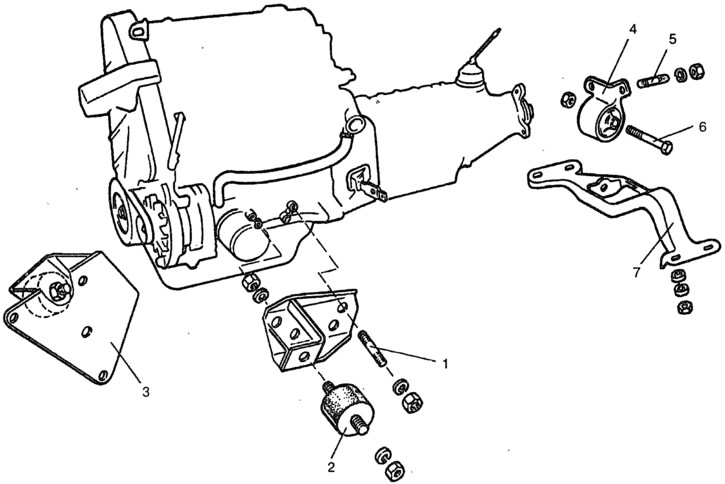

Hang the TCO-3/379 nataltraverse and lock the engine on the right side by the bracket mounted on the front exhaust manifold mounting stud, and on the left side by the clutch cover mounting hole. Slightly tension the hoist chain, unscrew the nuts securing the pillows 2 (pic. 9-27) front engine mount to the front mount cross member and remove the engine from the compartment.

Pic. 9-27. Engine Mount:

1 - stud for fastening the left engine mount bracket; 2 - pillow; 3 - right engine mount bracket assembly with a pillow; 4 - bracket with support for the rear engine mount; 5 - hairpin; 6 - bolt; 7 - cross member of the rear engine mount.

Remove the starter heat shield and starter. Loosen the clutch mounting bolts and remove it.

When installing the engine, the following operations must be performed:

- install the cooling system hoses, connectors and clamps;

- check the condition of the radiator (scale, leak, damage);

- check the operation of the radiator cooling fan;

- check the seal and valve of the radiator cap;

- install new air and fuel filter elements;

- fill the engine with oil;

- adjust the controls;

- fill the cooling system by removing air pockets;

- start and warm up the engine;

- adjust idling;

- check lubrication and cooling systems for leaks.

Pay special attention to connecting the engine to the gearbox: the input shaft must fit exactly into the splines of the clutch disc.