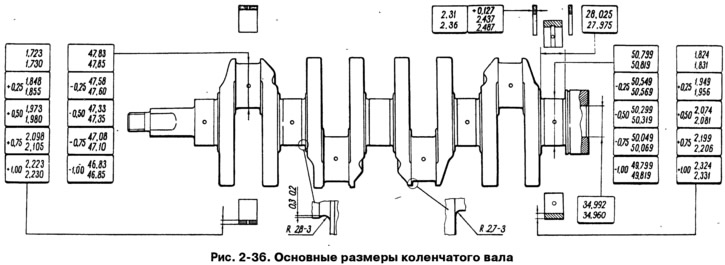

Crankshaft - cast, cast iron, five-bearing. It is possible to regrind the crankshaft journals during repairs with a diameter reduction of 0.25; 0.5; 0.75; and 1 mm.

The axial movement of the crankshaft is limited by two thrust half rings. They are inserted into the sockets of the cylinder block on both sides of the rear main bearing, and a ceramic-metal semi-ring is placed on the back (yellow), and from the front side - steel-aluminum. Semi-rings are made in two sizes - normal and increased in thickness by 0.127 mm.

Crankshaft bearing shells - thin-walled, steel-aluminum. The upper liners 1, 2, 4 and 5 of the crankshaft bearings have a groove on the inner surface, and the lower liners do not have a groove. Inserts 3rd support (upper and lower) without groove. Connecting rod bearings (upper and lower) also without groove.

Repair liners are made of increased thickness under the crankshaft journals, reduced by 0.25; 0.5; 0.75 and 1 mm.

Flywheel - cast iron, cast, with a pressed steel gear rim for starting the engine with a starter. The flywheel is centered by the front bearing of the drive shaft of the gearbox, pressed into the crankshaft.

On the rear surface of the flywheel, near the gear rim, there is a mounting mark in the form of a conical hole. It should be against the connecting rod neck of the fourth cylinder.