Piston - aluminum cast. In the manufacture of the mass of pistons is strictly maintained. Therefore, when assembling the engine, it is not required to select pistons of the same group by weight.

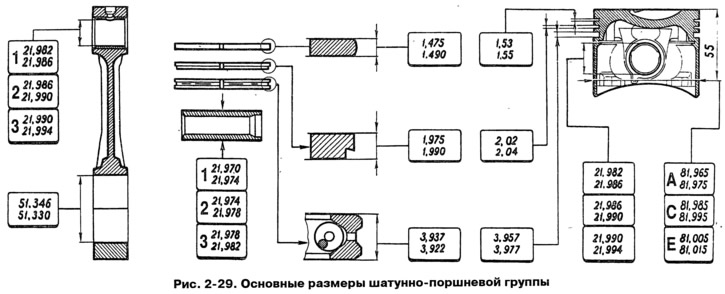

The outer diameter of the pistons are divided into five classes (A, B, C, D, E) through 0.01 mm. The outer surface of the piston has a complex shape. It is conical in height and oval in cross section. Therefore, it is necessary to measure the piston diameter only in a plane perpendicular to the piston pin, at a distance of 55 mm from the piston crown.

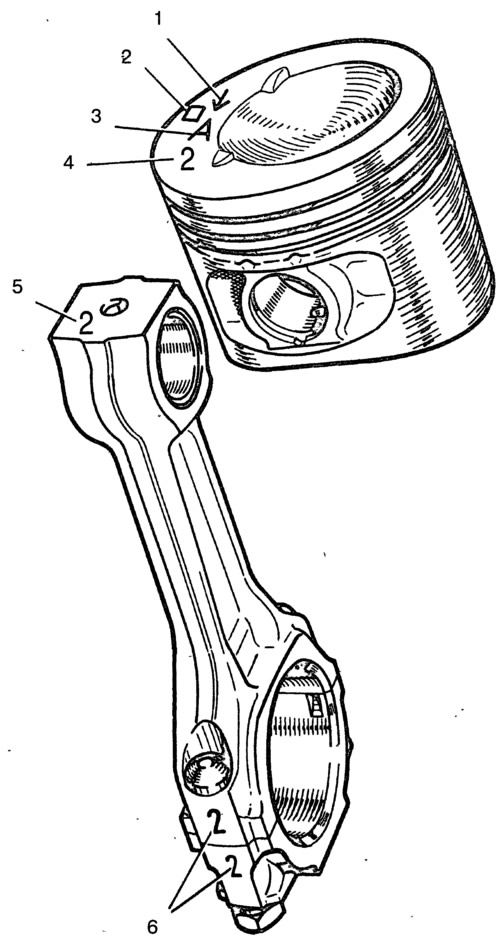

According to the diameter of the hole for the piston pin, pistons are divided into three classes (1, 2, 3) through 0.004 mm. Piston diameter classes and piston pin bores are stamped on the piston crown (pic. 2-30).

Pic. 2-30. Piston and connecting rod markings:

1 - arrow for orienting the piston in the cylinder; 2 - repair size; 3 - piston class; 4 - hole class for the piston pin; 5 - connecting rod class according to the hole for the piston pin; 6 - cylinder number.

Pistons of repair dimensions are manufactured with an outer diameter increased by 0.4 and 0.8 mm. On the bottoms of these pistons, markings are made in the form of a triangle or square. A triangle corresponds to an increase in the outer diameter of 0.4 mm, and a square to 0.8 mm.

The arrow on the bottom of the piston shows how to correctly orient the piston when it is installed in the cylinder. It should be directed towards the camshaft drive.

piston pin - steel, hollow, floating type, i.e. rotates freely in the piston bosses and the connecting rod bushing. The pin is fixed in the piston with two steel retaining rings.

According to the outer diameter, the fingers are divided into three classes through 0.004 mm. The class is marked with paint on the end of the finger: the blue mark is the first, the green mark is the second, and the red mark is the third class.

Piston rings - made of cast iron. The top compression ring is with a chrome-plated barrel-shaped outer surface. Bottom compression ring scraper type. Oil scraper ring - with chrome-plated working edges and with expanding coil spring (expander).

On rings of the repair sizes digital marking is put «40» or «80», which corresponds to an increase in the outer diameter of 0.4 or 0.8 mm.

connecting rod - steel, forged. It is processed together with the cover, and therefore they are not interchangeable individually. In order not to confuse caps and connecting rods during assembly, the number 6 is stamped on them (pic. 2-30) the cylinder in which they are installed. When assembling, the numbers on the connecting rod and cap must be on the same side.

A steel-bronze bushing is pressed into the upper head of the connecting rod. According to the diameter of the hole of this bushing, the connecting rods are divided into three classes through 0.004 mm (just like pistons). Class number 5 is stamped on the upper head of the connecting rod.

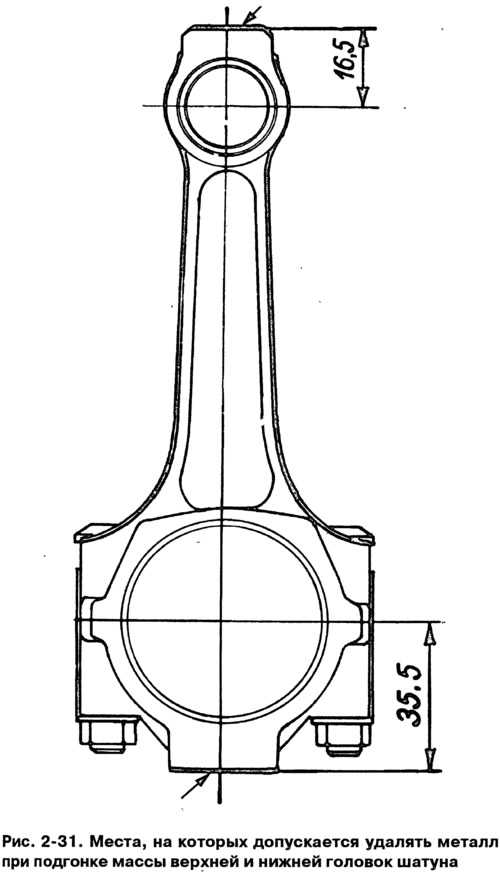

By the mass of the upper and lower heads, the connecting rods are divided into classes (tab. 2-1), marked with paint on the rod of the connecting rod. Connecting rods of the same weight class must be installed on the engine. You can adjust the mass of connecting rods by removing metal from the bosses on the heads to the minimum sizes of 16.5 and 35.5 mm (pic. 2-31).

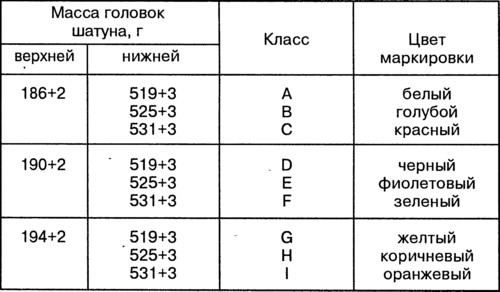

Table 2-1. Connecting rod classes by weight of the upper and lower heads