Examination

Wash the cylinder block thoroughly and clean the oil passages. After blowing and drying with compressed air, inspect the cylinder block. Cracks in bearings or other places in the cylinder block are not allowed.

If there is a suspicion that coolant has entered the crankcase, then check the tightness of the cylinder block on a special stand. To do this, after plugging the holes in the cooling jacket of the cylinder block, inject water at room temperature into it at a pressure of 0.3 MPa (3 kgf/cm2). Within 2 minutes there should be no leakage of water from the cylinder block.

If oil gets into the coolant, then without completely disassembling the engine, check for cracks in the cylinder block in the areas of the oil channels. To do this, drain the coolant from the cooling system, remove the cylinder head, fill the cooling jacket of the cylinder block with water and supply compressed air to the vertical oil channel of the cylinder block. If air bubbles appear in the water filling the cooling jacket, replace the cylinder block.

Check the split plane of the cylinder block with the head using a ruler and a set of feeler gauges. The ruler is installed along the diagonals of the plane and in the middle in the longitudinal direction and across. The flatness tolerance is 0.1 mm.

Cylinder repair

Check if the wear of the cylinders exceeds the maximum allowable - 0.15 mm.

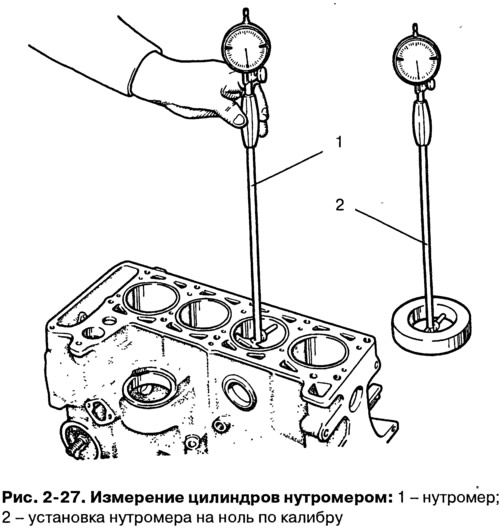

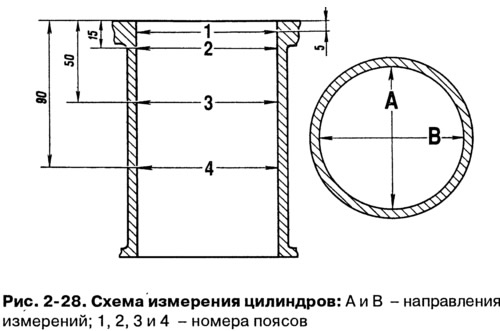

Cylinder diameter is measured with a bore gauge (pic. 2-27) in four zones both in the longitudinal and transverse directions of the engine (pic. 2-28). Caliber 67.8125.9502 is used to set the inside gauge to zero.

In the belt zone 1, the cylinders practically do not wear out. Therefore, by the difference in measurements in the first and other zones, one can judge the amount of cylinder wear.

If the maximum wear value is more than 0.15 mm, bore the cylinders to the nearest repair size, leaving an allowance of 0.03 mm for the diameter for honing. Then honing the cylinders, maintaining such a diameter that when installing the selected repair piston, the estimated clearance between it and the cylinder was 0.025-0.045 mm.