Cylinder head

Wash the cylinder head thoroughly and clean the oil passages. Remove carbon deposits from the combustion chambers and from the surface of the exhaust channels with a wire brush.

Inspect the cylinder head. Cracks in any places of the cylinder head are not allowed. If you suspect that coolant has entered the oil, check the tightness of the cylinder head.

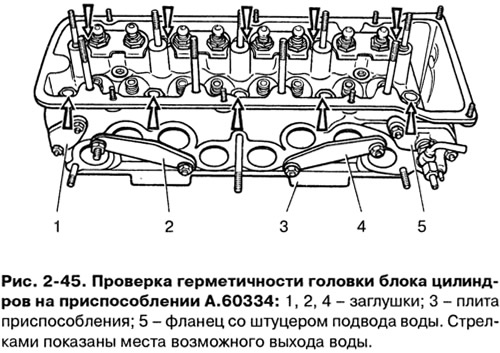

To check the tightness, close the holes in the cooling jacket of the cylinder head with the plugs included in the tool kit A.60334 (pic. 2-45). Pump water into the cylinder head cooling jacket with a pressure of 0.5 MPa (5 kgf/cm2). Within 2 minutes there should be no leakage of water from the cylinder head.

You can also check the tightness of the cylinder head with compressed air, for which also install the plugs of tool A.60334 on the cylinder head. Immerse the cylinder head in a bath of water heated to 60-80°C and let it warm up for 5 minutes. Then supply compressed air inside the head at a pressure of 0.15-0.2 MPa (1.5-2 kgf/cm2). Within 1-1.5 minutes, no air bubbles should be observed from the head.

Valve seats

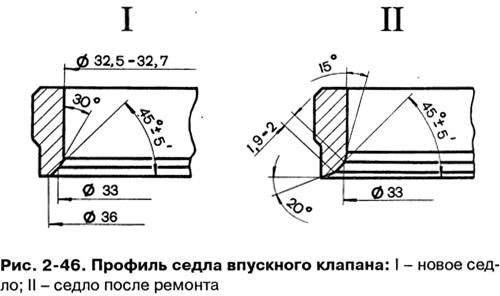

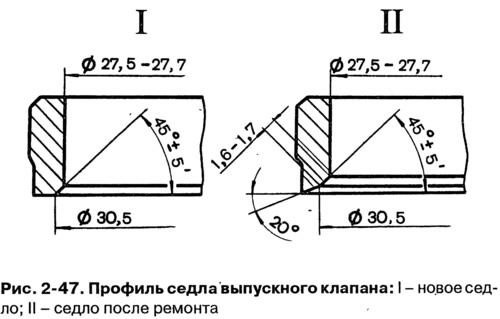

The shape of the chamfers of the valve seats is shown in fig. 2-46 and 2-47. On the working chamfers of saddles (valve contact area) there should be no pitting, corrosion or damage. Minor damage can be repaired by grinding the seats, removing as little metal as possible. You can grind both manually and with a grinder.

To grind the seats, install the cylinder head on a stand, insert the rod A.94059 into the valve guide and clean the chamfers of the seats from carbon deposits with A.94031 and A.94092 drills for exhaust valve seats and A.94003 and A.94101 drills for intake valve seats. Countersinks are put on the spindle A.94058 and centered by the guide rod A.94059. These rods are available in two different diameters: A.94059/1 for intake valve guides and A.94059/2 for exhaust valve guides.

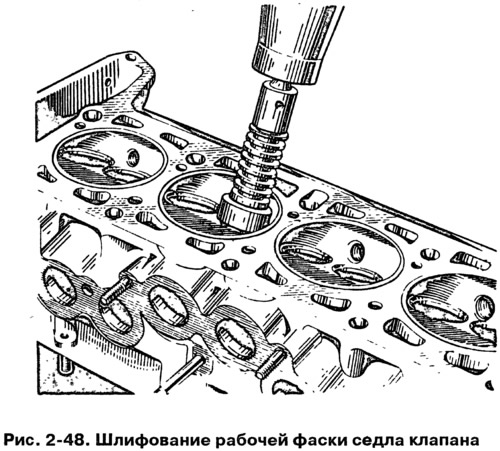

Put on the guide rod A.94059 spring A.94069/5, install on the spindle A.94069 conical circle A.94078 for exhaust valve seats or circle A.94100 for inlet valve seats, fix the spindle in a grinder and grind the valve seat (pic. 2-48).

At the moment the wheel touches the seat, the machine must be turned on, otherwise vibration will occur and the chamfer will be incorrect. It is recommended to dress the wheel more often with a diamond tool.

For exhaust valve seats, bring the width of the working chamfer to the values specified in fig. 2-46, countersink A.94031 (angle 20°) and countersink A.94092, which eliminates hardening on the inner diameter. Countersinks are put on the A.94058 spindle and, just as in grinding, are centered with the A.94059 rod.

At the inlet valve seats, bring the width of the working chamfer to the values specified in fig. 2-47, first processing the internal chamfer with a countersink A.94003 (pic. 2-49) until a diameter of 33 mm is obtained, and then a chamfer of 20°with a countersink A.94101 until a working chamfer with a width of 1.9-2 mm is obtained.

Valves

Remove soot from valves. Check if the rod is deformed and if there are cracks on the plate. Replace damaged valve.

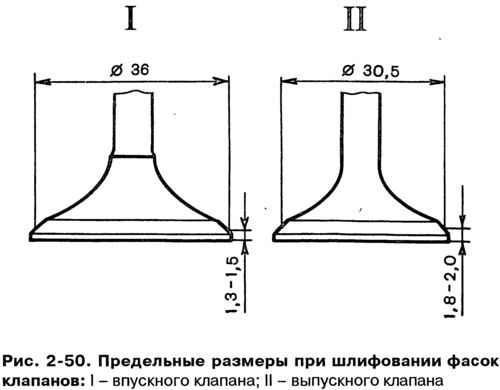

Check the condition of the valve face. In case of minor damage, it can be sanded, maintaining a chamfer angle of 45°30'±5'. In this case, the distances from the lower plane of the valve disc to the base diameters (36 and 30.5 mm) should be within the limits shown in Fig. 2-50.

Valve guides

Check the clearance between the valve guides and the valve stem by measuring the diameter of the valve bush and the bore of the valve guide.

Estimated clearance for new bushings: 0.022-0.055 mm for intake valves and 0.029-0.062 mm for exhaust valves; maximum allowable clearance (when worn) - 0.3 mm, provided there is no increased noise of the gas distribution mechanism.

If the increased clearance between the guide sleeve and the valve cannot be eliminated by replacing the valve, then replace the valve sleeves using the A.60153/R tool for pressing and pressing in (pic. 2-51).

Press in the guide bushings with the retaining ring on until it stops against the body of the cylinder head.

After pressing, expand the holes in the guide bushings with A.90310/1 reamers (for intake valve bushings) and A.90310/2 (for exhaust valve bushings).

When repairing the engine, always replace the oil deflector caps with new ones.

Replace damaged oil seals with the cylinder head removed. To press the caps, use the mandrel 41.7853.4016.

Springs

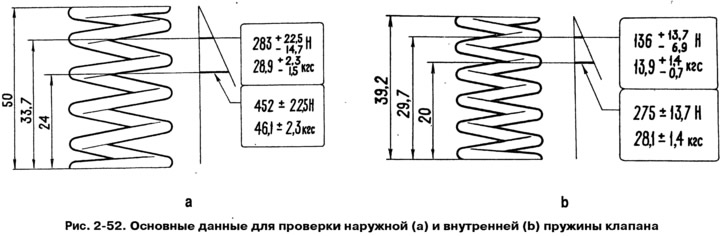

Make sure that the springs are not cracked and their elasticity has not decreased, for which check their deformation under load (pic. 2-52).

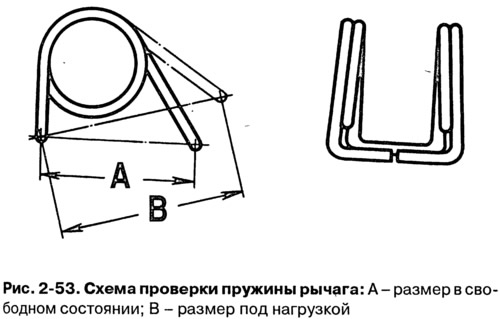

For lever springs (pic. 2-53) size A (free spring) should be 35 mm, and dimension B under load 51-73.5 N (5.2-7.5 kgf) - 43 mm.

Bolts of fastening of a head of cylinders

With repeated use of the bolts, they are pulled out. Therefore, check whether the length of the bolt shaft exceeds (head length not included) 120 mm, if it is more, then replace the bolt with a new one.

When replacing bolts, do not confuse them with bolts from other VAZ engines of the same type (2101, 21011, 2103, 2107, 2121), having similar bolts, but from a different steel.

Engine bolts 21213 have a thread length of 70 mm (other engines 30 mm), and 21213 bolts do not have a distinguishing mark (wells with a diameter of 7.5 mm) in the keyhole.

Valve levers

Check the condition of the working surfaces of the lever mating with the valve stem, with the camshaft cam and with the spherical end of the adjusting bolt. If nicks or marks appear on these surfaces, replace the lever with a new one.

If deformation or other damage is found on the lever adjusting bolt bushing or on the bolt itself, also replace these parts.