Crankshaft

Inspect the crankshaft. Cracks anywhere on the crankshaft are not allowed. Scratches, nicks and risks are not allowed on surfaces mating with the working edges of the stuffing boxes.

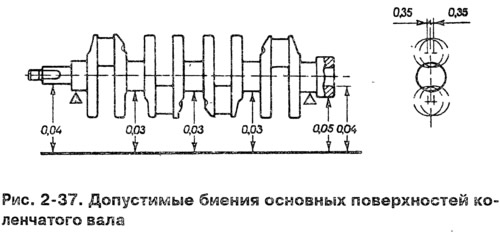

Install the crankshaft with extreme main journals on two prisms (pic. 2-37) and check the beat indicator:

- root necks (no more than 0.03 mm);

- landing surfaces for the sprocket and bearing of the drive shaft of the gearbox (no more than 0.04 mm);

- seal mating surface (no more than 0.05 mm).

Measure the diameters of the main and connecting rod journals. The necks should be ground if their wear is more than 0.03 mm or the ovality of the necks is more than 0.03 mm, and also if there are scratches and marks on the necks.

Grind the necks with a reduction in diameter to the nearest repair size (rice. 2-36).

When grinding, maintain the dimensions of the fillets of the necks, similar to those indicated on rice. 2-36 for normal crankshaft sizes. The ovality and taper of the main and connecting rod journals after grinding should be no more than 0.005 mm.

The displacement of the axes of the connecting rod journals from the plane passing through the axes of the connecting rod and main journals after grinding should be within±0.35 mm (pic. 2-37). To check, install the shaft with extreme main journals on the prisms and set the shaft so that the axis of the connecting rod journal of the first cylinder is in a horizontal plane passing through the axis of the main journals. Then use an indicator to check the vertical displacement of the crankpins of the 2nd, 3rd and 4th cylinders relative to the crankpin of the 1st cylinder.

After grinding the necks, polish them with diamond paste or GOI paste.

After grinding and subsequent finishing of the necks, remove the plugs of the oil channels, and then process the sockets of the plugs with a cutter A.94016/10, put on the spindle A.94016. Thoroughly wash the crankshaft and its channels to remove abrasive residues and blow with compressed air. Using mandrel A.86010, press in new plugs and mark each at three points with a center punch.

On the first cheek of the crankshaft, mark the amount of reduction of the main and connecting rod journals (for example, K 0.25; Ш 0.50).

Inserts

No adjustments can be made on the inserts. In case of scuffing, scratches or delaminations, replace the liners with new ones.

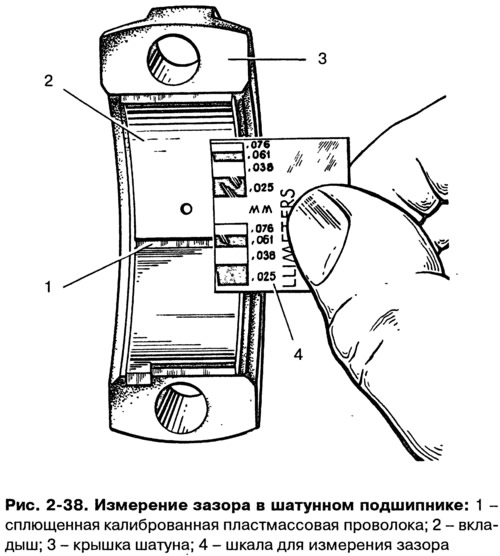

The gap between the liners and the crankshaft journals is checked by calculation (measuring the details). It is convenient to use a calibrated plastic wire to check the gap. In this case, the verification method is as follows:

- thoroughly clean the working surfaces of the inserts and the corresponding neck and place a piece of plastic wire on its surface;

- install a connecting rod with a cap or a main bearing cap on the neck (depending on the type of checked neck) and tighten nuts or bolts. Tighten the nuts of the connecting rod bolts to a torque of 51 Nm (5.2 kgf·m), and the bolts of the main bearing caps - with a torque of 80.4 N·m (8.2 kgf·m);

- remove the cover and, using the scale printed on the package, determine the size of the gap by the flattening of the wire (pic. 2-38).

The nominal design clearance is 0.02-0.07 mm for connecting rod and 0.026-0.073 mm for main journals. If the clearance is less than the limit (0.1 mm for connecting rod and 0.15 mm for main journals), you can use these earbuds again.

If the gap is greater than the limit, replace the liners on these necks with new ones.

If the crankshaft journals are worn out and are ground to a repair size, then replace the liners with repair ones (increased thickness).

Thrust half rings

As well as on the inserts, no fitting operations can be performed on the half rings. In case of scuffing, risks or delaminations, replace the half rings with new ones.

Half rings are also replaced if the axial clearance of the crankshaft exceeds the maximum allowable - 0.35 mm. Select new half rings with a nominal thickness or increased by 0.127 mm to obtain an axial clearance in the range of 0.06-0.26 mm.

The axial clearance of the crankshaft is checked using an indicator, as described in chapter «Engine Assembly» (pic. 2-14).

The axial clearance of the crankshaft can also be checked on the engine installed on the vehicle. In this case, the axial movement of the crankshaft is created by pressing and releasing the clutch pedal, and the gap is determined by the movement of the front end of the crankshaft.

Flywheel

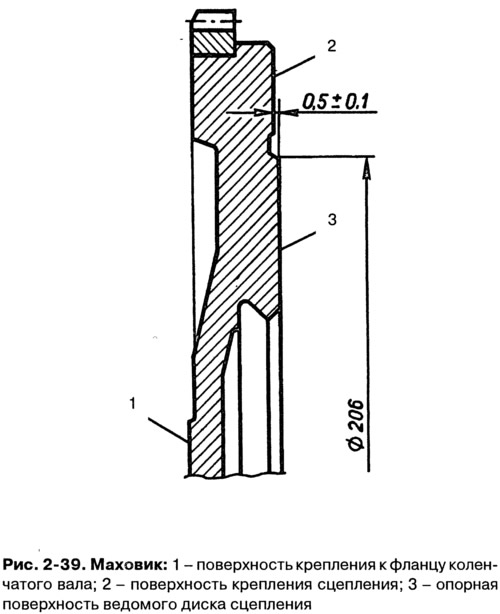

Check the condition of the gear rim and if the teeth are damaged, replace the flywheel. If the flywheel has discoloration on the surface 3 (pic. 2-39), it is necessary to check the tightness of the rim on the flywheel. The rim must not rotate with a torque of 590 Nm (60 kgf·m).

On surface 1 of the flywheel adjacent to the crankshaft flange, and on surface 3 under the clutch disc, scratches and scuffs are not allowed.

Remove scratches and scuffs on surface 3 with a groove, removing a metal layer no more than 1 mm thick. At the same time, also grind surface 2, maintaining the size (0,5±0,1) mm. When turning, it is necessary to ensure the parallelism of surfaces 2 and 3 relative to surface 1. The non-parallelism tolerance is 0.1 mm.

Install the flywheel on the mandrel, centering it on the mounting hole with an emphasis on surface 1, and check the runout of planes 2 and 3. At the extreme points, the indicator should not show runout exceeding 0.1 mm.