Camshaft

On the bearing journals of the camshaft, scuffing, nicks, scratches, aluminum enveloping from bearing housings are not allowed. On the working surfaces of the cams, wear of more than 0.5 mm is not allowed, as well as scuffing and wear of the cams in the form of a cut.

Install the camshaft with the outer journals on two prisms located on the calibration plate, and measure the radial runout of the middle journals with an indicator, which should be no more than 0.04 mm. If the runout exceeds the specified value, then straighten the shaft on a straightening press.

Camshaft bearing housing

Rinse and clean the bearing housing and oil passages.

Check the diameter of the holes in the supports. If the clearance between the camshaft journals and bearings exceeds 0.2 mm (wear limit), replace the bearing housing.

Internal bearing surfaces must be smooth, free of burrs; if there is damage, replace the bearing housing. Check for cracks on the case. If there are cracks, replace the camshaft bearing housing.

Tensioner

If there is a jamming of the tensioner plunger in the housing, then it is necessary to disassemble the chain tensioner. To do this, unscrew the cap locking nut 1 (rice. 2-56), push the plunger 6 in as far as possible and tighten the cap nut. File the edges of the body hole in the punching points B and remove the plunger 6 with the spring 4. Then unscrew the cap nut and remove the rod 3 together with the spring 7 and washer 5. Remove the clamping cracker 8 from the cap nut 1 by removing the spring ring 9.

Check for burrs 8, rod 3 and plunger 6 for burrs, and for mating surfaces of the shoe and plunger of the chain tensioner with deep scratches. Replace damaged parts.

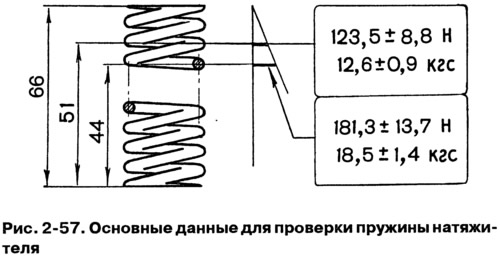

The elasticity of the tensioner spring must be within the limits indicated in Fig. 2-57; If the spring is less elastic, replace it.

Check for excessive wear on the shoe and damper; if necessary, replace them.

The tensioner is assembled in the reverse order of disassembly. After installing the plunger, punch out body 2 at three points B. At the same time, the protrusions from punching should not touch surface A when the plunger moves,

Note. On some of the produced cars, tensioners are installed, in which a spring ring is used instead of opening the body.

Camshaft drive chain

Rinse the chain in kerosene, and then check the condition of its links. On rollers and cheeks, chips, cracks and other damage are not allowed.

When the engine is running, the chain stretches. It is considered serviceable as long as the tensioner provides its tension, i.e. if the chain is extended by no more than 4 mm.

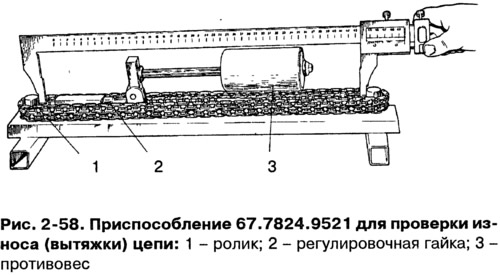

Check the chain extractor on tool 67.7824.9521 (pic. 2-58), having two stepped rollers 1, on which the chain is put on. With the help of counterweight 3, the chain is stretched with a force of 294 N (30 kgf) or 147 N (15 kgf). The adjusting nut 2 ensures that the axis of the counterweight is parallel to the base of the device.

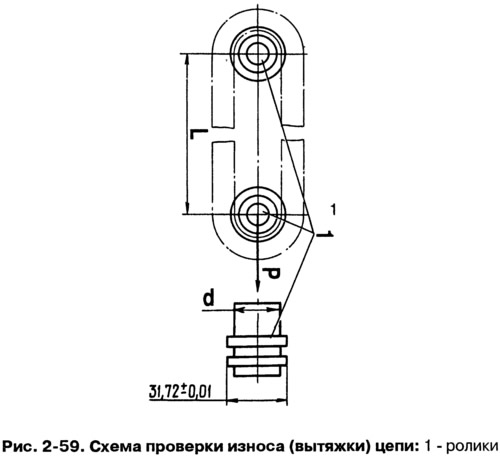

Stretch the chain with a force of 294 N (30 kgf), putting the counterweight in the extreme right position, then reduce the force by 147 AND (15 kgf), by moving the counterweight to the extreme left position. Repeat both operations again and determine the chain extension by the distance L (pic. 2-59) between roller axes. By measuring the distance between the diameters d of the rollers with a caliper and adding the diameter d to it, you get the distance L between the axes of the rollers.

For a new chain, the distance L between the axes of the rollers is 495.4-495.8 mm; if the chain is extended to 499.5 mm, it should be replaced.

Lubricate the chain with engine oil before installing on the engine.