- apply evenly 3-4 g of Fiol-1 or Fiol-2U lubricant on splined joints;

- when connecting the parts, align the marks made on the detachable parts before disassembly;

- after assembling the spline connection, pressing the stuffing box by 0.3-0.5 mm with an axial load, crimp the clip on the groove of the fork.

Assemble the cardan joint in the following sequence:

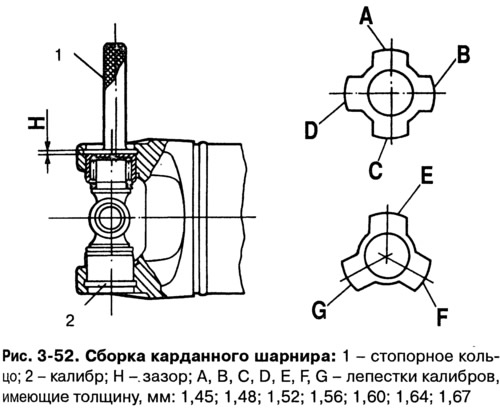

- after removing the old thickened grease, lubricate the inner surface of the bearing housings with grease No. 158 or Fiol-2U (0.8-1.2g per bearing). The spikes of the cross should not be covered with grease, so that an air cushion does not form during assembly. Insert the cross into the holes of the forks. Press the bearing into one hole of the fork and install the retaining ring 1 into the groove of the fork (pic. 3-52) 1.56 mm thick. Press the bearing into the other hole of the yoke until the opposite bearing rests against the end of the circlip. The pressing force must not exceed 15000 N (1500 kgf).

Using two gauges 2, having 4 and 3 petals of different thickness, respectively, determine which of the petals fits tightly into the gap H between the bottom of the bearing and the end of the fork groove, and install a retaining ring of the same thickness as the petal.

Note. One caliber has petals 1.45 thick; 1.48; 1.52; 1.56mm, other 1.60; 1.64; 1.67 mm.

If the petal of the smallest thickness (1.45mm) is not included in the gap H, then the ring 1 must be replaced with another one, 1.4 mm thick, and repeat the indicated operations.

If the petal is the thickest (1.67mm) enters the gap H loosely, it is necessary to install a ring 1.67 mm thick into this gap, and remove ring 1 and repeat all the above operations.

Note. It is recommended to measure the gap with gauge petals from the side of the pipe. Retaining rings come in eight sizes of spare parts (by thickness), each of which has a certain color: 1.45 - unpainted; 1.48 - yellow; 1.52 - brown; 1.56 - blue; 1.60 - black; 1.64; 1.67; 1.40 - colors are not indicated, and their thickness is determined by measurement.

After installing the retaining rings, hit the hinge forks with a plastic-headed hammer. Under the action of the impact, the gap between the bottom of the bearing and the retaining ring is selected, and gaps appear between the bearing housings and the ends of the cross spikes in the range of 0.01-0.04 mm. After assembly, check the ease of rotation of the forks and the balance of the shafts.

When assembling the intermediate shaft joint, use the techniques described in chapter «Front wheel drive». When assembling the separator 7 (rice. 3-49) install with a chamfer towards the drive shaft of the transfer case, and put Longtern-OO grease in the joint «Dow corning» in the amount of 20 cm3.