Attention! We carry out the work together with an assistant on a viewing ditch or lift.

Bleeding the brakes is necessary when replacing the brake fluid, as well as to remove air that has entered the hydraulic drive during the repair or replacement of individual components of the brake system.

Air is removed first from one circuit of the system, then from another. We start pumping from the right rear wheel cylinder.

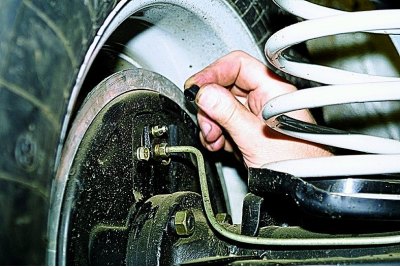

Remove the cap from the rear brake cylinder bleeder.

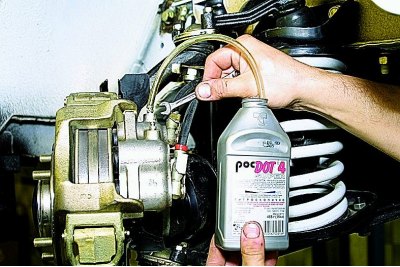

We put a transparent hose on the fitting, lowering its free end into the vessel.

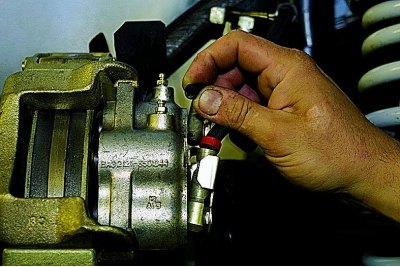

The assistant presses the brake pedal three to four times at intervals of one to two seconds and keeps the pedal depressed. key «for 8» unscrew the bleeder screw 1/2-3/4 turn. In this case, part of the brake fluid and air are forced out into the vessel, and the pedal is lowered to the floor. Air bubbles are clearly visible in the transparent hose. We wrap the bleed valve and repeat this operation until the exit of air bubbles completely stops.

When removing air from the system, we monitor the fluid level in the reservoir of the main brake cylinder and top it up if necessary.

Similarly, we pump the left rear wheel cylinder. Then we remove the air from the upper fittings of the left and right cylinder blocks of the front wheels.

Remove the cap of the upper fitting of the front wheel brake cylinder block (wheel removed for clarity).

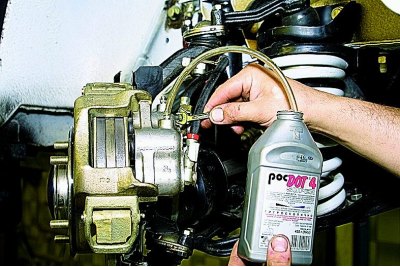

We pump the front brake cylinders of one circuit.

To pump another circuit, we remove air from the lower fittings of the front wheel cylinder blocks in random order.

Remove the cap from the lower fitting of the front wheel brake cylinder block.

We pump another circuit.

If there is no air in the system, the brake pedal must be «tough», i.e. when pressed, go no more than half the distance to the floor.