Remove the oil pan protection plate and the right engine mudguard (see Removing the oil pan protection plate and injection engine splash guards).

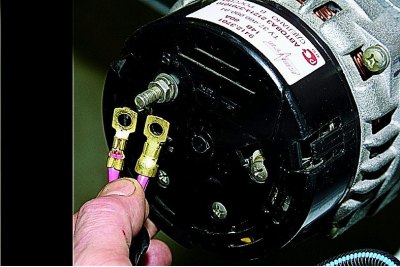

Disconnect the output wire «D» generator.

Sliding rubber cover, keyed «on 10» unscrew the nut securing the wires to the output «IN» …

...and take them off.

Remove the water pump drive belt (see Tension adjustment and replacement of the coolant pump drive belt).

head on «13» unscrew the nut of the bolt securing the generator to the tension bar.

key «at 13» unscrew the nut of the bolt of the lower fastening of the generator to the bracket on the cylinder block and remove the bolt. We take out the generator from a motor compartment downwards.

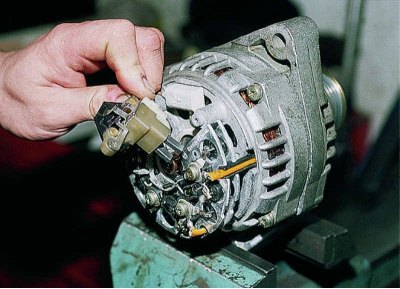

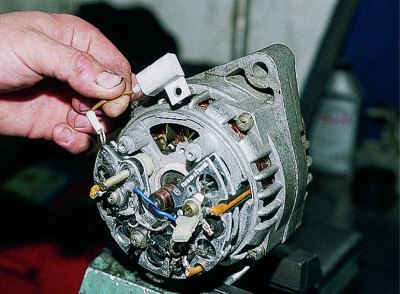

Opening the three protrusions of the casing,..

…remove it.

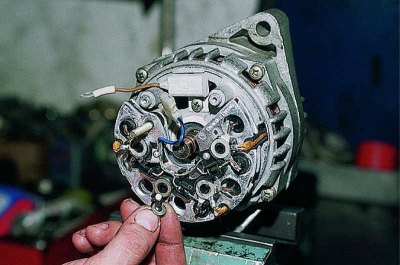

Using a Phillips screwdriver, unscrew the two screws..

... and remove the voltage regulator with a brush holder.

Disconnect the wire and remove the voltage regulator with the brush holder.

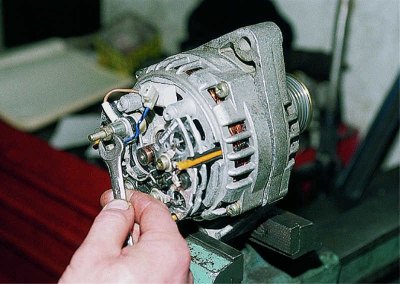

key «on 10» loosen the nut..

... remove the sleeve and the capacitor wire.

Unscrew the screw with a Phillips screwdriver,..

... remove the capacitor.

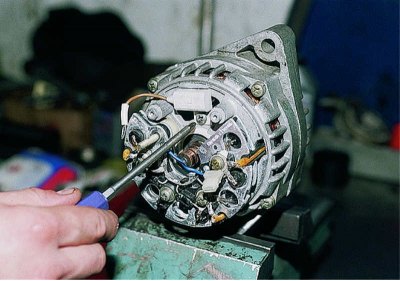

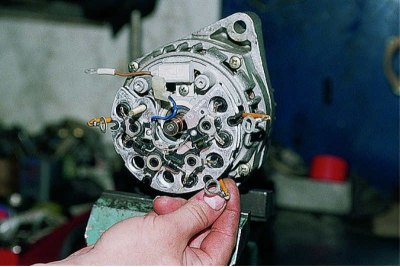

Using a Phillips screwdriver, unscrew the screw securing the rectifier unit and three screws securing the ends of the stator windings.

Insulating washers are put on the screws for fastening the ends of the stator windings.

We remove the ends of the stator windings..

... and remove the rectifier block.

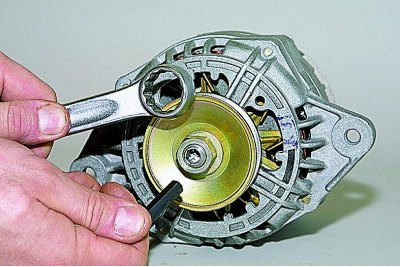

ring wrench «at 21» unscrew the pulley fastening nut, holding the rotor with a hexagon «for 8».

Remove the washer and parts of the pulley.

Remove the washer from the rotor shaft.

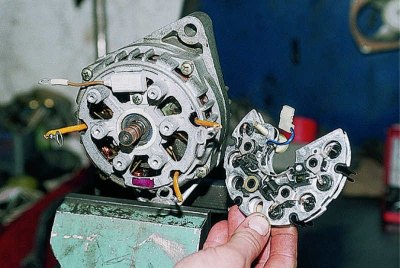

Using a Phillips screwdriver, unscrew the four screws holding the covers together.

With sharply sharpened scriber or paint, we mark the relative position of the covers and the stator for subsequent assembly.

Prying off with a screwdriver..

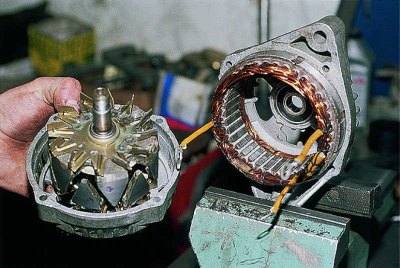

... we disconnect the front cover with the stator and the rear cover with the rotor.

Prying off the stator with a screwdriver,...

... take it out of the front cover.

A punch that abuts strictly against the end of the rotor shaft (so as not to damage the plastic sleeve located under the slip rings),…

... we knock out the rotor with the bearing from the back cover.

With a puller we press the bearing from the rotor shaft.

We press the new bearing onto the shaft with a suitable piece of pipe, applying force to the inner ring.

With a tester, we check the stator and rotor windings for an open or short to the housing.