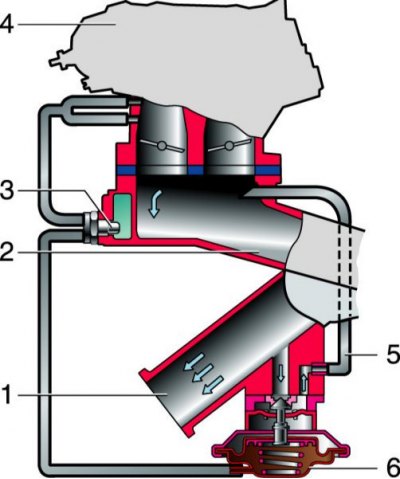

1 - exhaust manifold; 2 - inlet pipe; 3 - thermal vacuum switch of the recirculation valve; 4 - carburetor; 5 - recirculation tube; 6 - recirculation valve.

The exhaust gas recirculation system serves to reduce exhaust toxicity (by reducing the formation of nitrogen oxides). The principle of its operation is to dilute the fresh air-fuel mixture with exhaust gases taken from the engine exhaust manifold. It consists of a thermal vacuum switch screwed into the cooling jacket on the intake manifold, a recirculation valve bolted to the tide of the exhaust manifold, vacuum hoses and a steel exhaust gas return pipe.

On a cold engine (coolant temperature below 40-48°С) the thermal vacuum switch cuts off the vacuum supply to the recirculation valve - the system is not activated. When the engine warms up above the specified temperature, the switch opens the channel, connecting the space above the carburetor throttle with the recirculation valve. At idle and with a small opening of the damper, the vacuum above it is small; it is not enough to overcome the force of the valve spring, so it remains closed. With a larger throttle opening, the vacuum increases, and the recirculation valve opens, passing exhaust gases into the intake manifold.