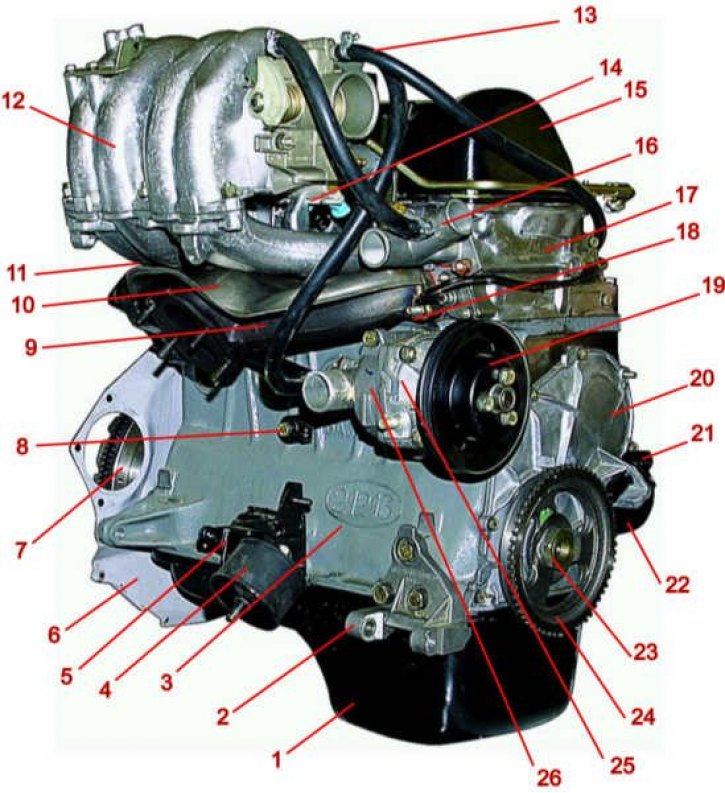

Engine VAZ-21214: 1 - oil pan; 2 – an arm of fastening of the generator; 3 - block of cylinders; 4 - pillow support of the power unit; 5 - arm support of the power unit; 6 - clutch housing cover; 7 - flywheel; 8 - knock sensor; 9 - exhaust manifold; 10 - heat shield of the inlet pipe; 11 - inlet pipe; 12 - receiver; 13 - throttle assembly; 14 - fuel rail; 15 – a cover of a head of the block of cylinders; 16 - outlet pipe of the cooling jacket; 17 – a head of the block of cylinders; 18 – hydraulic chain tensioner; 19 – a pulley of the pump of a cooling liquid; 20 – a cover of a drive of a camshaft; 21 - crankshaft position sensor; 22 - oil filter; 23 – a nut of fastening of a pulley of a cranked shaft; 24 - crankshaft pulley; 25 – a cover of the pump of a cooling liquid; 26 - coolant pump housing.

Petrol, four-stroke, four-cylinder, eight-valve, in-line, with an overhead camshaft.

The order of operation of the cylinders: 1-3-4-2, counting - from the crankshaft pulley. Power supply system - distributed injection, engine management - controller «BOSCH MP7.0» (toxicity standards Euro-2). A catalytic converter is installed in the exhaust system.

Right side of the engine (along the car) located: a receiver with a throttle assembly, a throttle position sensor and an idle speed controller, an intake pipe and an exhaust manifold, a fuel rail with injectors and a fuel pressure regulator, knock sensors and coolant temperature (for injection system), alternator, thermostat, starter (on the clutch housing). The air filter housing with mass air flow sensor is mounted on a separate bracket to the right of the engine.

On the left side of the engine are: spark plugs and high voltage wires, ignition module, oil level gauge, oil filter, coolant temperature and oil pressure sensors (control devices). Front: coolant pump and alternator drive (V-belt), crankshaft position sensor.

The cylinder-piston group is the same as that of the engine mod. 21213 (see Engine VAZ-21213). On the toe of the crankshaft, a pulley for driving the generator and coolant pump with a toothed disk is installed - for reading information by the crankshaft position sensor. Disc has 58 teeth (the circle is divided into 60 teeth, but two are missing, forming a cavity - this is necessary to obtain a synchronization pulse with each revolution of the crankshaft). Camshaft cover mod. 21214 differs from cover mod. 21213 the presence of a tide with a hole for the crankshaft position sensor.

The timing mechanism is driven by a single-row chain. Accordingly, the sprockets of the crankshaft and camshaft, as well as the oil pump drive shaft, are also single-row; they are not interchangeable with engine parts mod. 21213. At the same time, the number of teeth of the oil pump drive shaft sprocket was reduced from 38 to 30 (synchronization of revolutions for the operation of the ignition distributor sensor is not needed here), thereby increasing the performance of the oil pump (this is necessary due to the appearance of a hydraulic chain tensioner and hydraulic bearings for valve levers).

Tensioner shoe mod. 21214 significantly longer than shoe mod. 21213. It, like the chain guide, is made of wear-resistant plastic. Their attachment points have also been moved. The axis of rotation of the tensioner shoe is located at the bottom of the cylinder block, to the right of the crankshaft sprocket (in its place in the mod engine. 21213 was a restrictive finger).

Tensioner - spring-hydraulic: pre-tensioning the chain (with engine off) provided by a spring, working (after engine start) - oil pressure under pressure, which is supplied through a steel tube from an adapter under the emergency oil pressure sensor.

Instead of adjusting bolts in the valve mechanism, hydraulic supports of the valve levers are installed (clearance hydraulic compensators). They are supplied with oil under pressure, supplied through a separate tube from the hole in the camshaft bearing housing near the middle stud of its fastening. Due to the fact that there are practically no gaps in the valve mechanism, springs are not installed that pressed the valve levers on the mod engine. 21213. The shape of the camshaft cams is also different.