We connect fuel pipes to the ramp and connect its electrical connector.

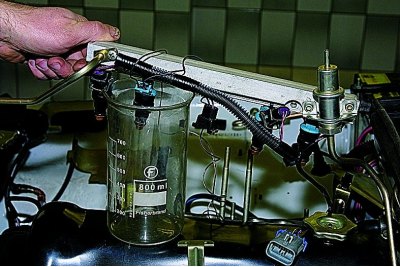

Having placed transparent flasks under the nozzles, we turn the engine with a starter.

Spray torches and the amount of fuel injected into each flask for a certain period of time should not differ noticeably.

Separately, we check each nozzle by disconnecting the electrical connector from it. Turning on the ignition, we apply 12 V voltage from the battery to it with two wires.

A characteristic jet should come out of the nozzle sprayer.

After turning off the power from the nozzle, we check if fuel is leaking through the nozzle hole.

We check the resistance of the injector winding with a tester.

It should be in the range of 11-15 ohms.

If the electrical resistance of the nozzle is not correct, the performance and spray pattern are very different from those of other nozzles, if the nozzle is leaking, then it must be replaced.