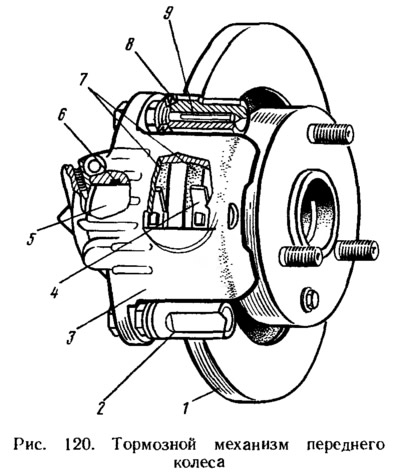

A hollow piston 5 with a sealing ring 6 is installed in the cylinder cavity. Due to the elasticity of this ring and a groove of a special configuration, a certain gap between the pads and disk 1 is maintained in the cylinder. The cylinder cavity is protected by a rubber cap.