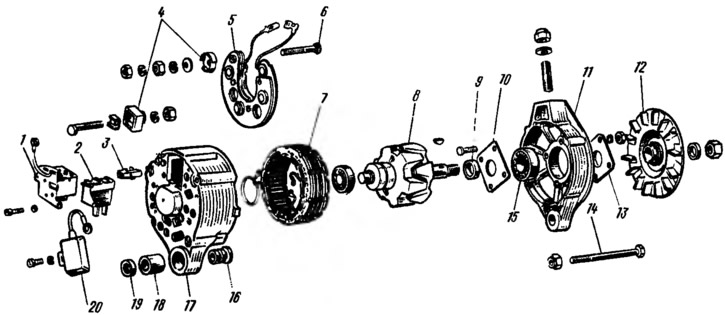

Pic. 145. Generator details: 1 - voltage regulator; 2 - brush holder; 3 - block output of additional diodes; 4 - insulating bushings; 5 - rectifier block; 6 - contact bolt; 7 - stator; 8 - rotor; 9 - remote bushing; 10 — internal washer of fastening of the bearing; 11 - cover on the drive side; 12 - pulley; 13 — an external washer of fastening of the bearing; 14 - coupling bolt; 15 - front ball bearing of the rotor; 16 - sleeve; 17 - cover from the side of slip rings; 18 - buffer sleeve; 19 - clamping sleeve; 20 - capacitor.

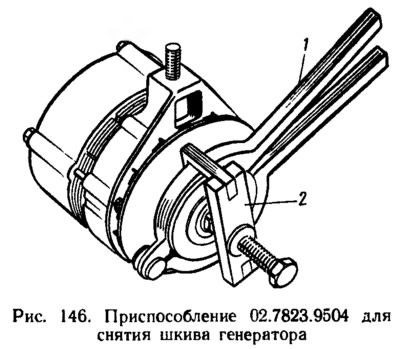

Unscrew the nuts of the coupling bolts 14 and remove the cover 11 of the generator together with the rotor and pulley. The rotor is clamped in a vice, the pulley nut is unscrewed and the pulley is removed from the rotor shaft with a puller 02.7823.9504. Remove the segment key from the groove on the shaft and remove the cover 11.

Puller 02.7823.9504 (pic. 146) consists of two steel half-rings 1, which are inserted into the pulley stream, and a conventional puller 2. The puller's paws are grabbed by the half-rings, and the bolt rests against the end of the generator shaft. The half rings have the same section as the alternator drive belt. On the one hand, they are hinged, and on the other hand, they are equipped with levers that are compressed by hand when the pulley is removed.

Unscrew the nuts of the screws connecting the tips of the valves with the terminals of the stator winding and remove the stator 7 (see fig. 145) from cover 17 of the generator. Unscrew the nut of the contact bolt 6, disconnect the wire plug of the additional diodes from the block 3 and remove the rectifier unit 5.

Assemble the generator in reverse order. The misalignment of the holes in the paws of the generator covers should be no more than 0.4 mm. Therefore, during assembly, it is necessary to insert into these holes a stepped cylindrical test mandrel, having a diameter of 12 mm on one side and 22 mm on the other. The convex side of the pulley spring washer must be in contact with the nut. The pulley nut is tightened to a torque of 38.4-88 Nm.

In order to avoid breakage of the brushes, before installing the voltage regulator with the brush holder in place, it is necessary not to fully insert the brush holder into the regulator, but only partially push it in and insert it into the generator in this form. After installing the brush holder in place in the generator cover, lightly press the regulator to push it into the generator.

Brush holder replacement

If the brushes are worn out and protrude from the brush holder by less than 5 mm, then replace the brush holder with brushes. For replacement, the brush holder is pulled out of the voltage regulator housing by pressing on the output «IN». Before installing the voltage regulator with a new brush holder, blow out the socket in the generator from coal dust and wipe it from oil mixed with coal dust.

Rotor bearing replacement

To remove the defective bearing from the cover on the drive side, unscrew the nuts of the screws that tighten the bearing fastening washers, remove the washers with screws and press the bearing out on a hand press. If the nuts do not loosen (the ends of the screws are punched), then cut off these ends.

It is only possible to install a new bearing in the generator cover if the bearing hole is not deformed. The hole diameter should not exceed 42 mm. If the hole has a larger diameter or is deformed, the cover is replaced with a new one.

The bearing is pressed into the cover on a press and then clamped between two washers tightened with screws and nuts. After tightening the nuts, the ends of the screws are punched out.

When replacing the rotor bearing on the side of the slip rings, the cover must also be replaced at the same time, because if the bearing is damaged, the seat in the cover is also damaged.

Replacement of additional diodes

To replace, solder the leads of the damaged diode and carefully remove it from the plastic holder, avoiding sharp blows to the rectifier unit. Then they clean the installation site of the diode from the remnants of epoxy, install and solder a new diode. The output of the diode with a color mark is soldered to the terminals of the valves. After soldering, glue the body of the diode to the holder with epoxy resin.