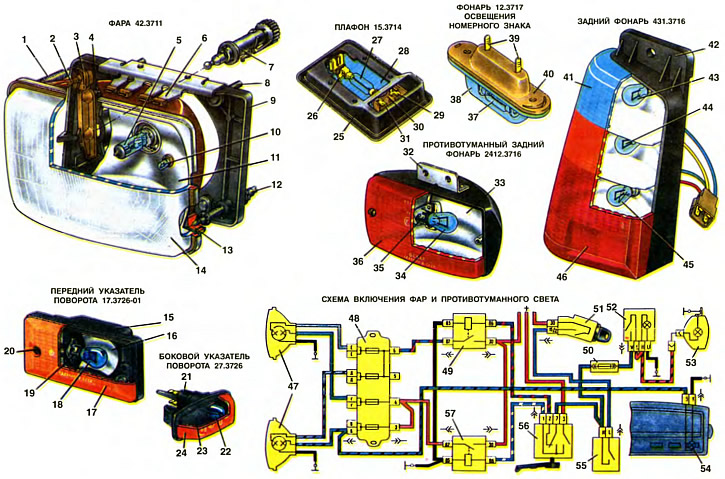

1. Return spring. 2. Upper reflector holder. 3. Lever. 4. Screw for vertical adjustment of the beam SV6TE. 5. Lamp AKG12-60+55. 6. Bracket. 7. Set screw. 8. Headlamp mounting screw. 9. Headlight housing. 10. Lamp A12-4 side light. 11. Reflector. 12. Screw for horizontal adjustment of the beam of light. 13. Lower reflector holder. 14. Glass headlight diffuser. 15. Housing front turn signal. 16. Reflector. 17. Lens front turn signal. 18. Lamp A12-21-3. 19. Lamp holder. 20. Screw for fastening the diffuser. 21. Plug holder with lamp socket. 22. Lamp A12-3-1. 23. Housing side direction indicator. 24. Diffuser pointer. 25. Plafond body. 26. Rack-plug for supplying voltage and mounting the lamp. 27. 37. Lamp AS 12-5. 28. Diffuser ceiling. 29. Plug for ground connection. 30. Switch. 31. Plug for connection to switches in door pillars. 32. An arm of fastening of a lantern. 33, 40, 42. Lantern body. 35. Lamp holder. 36, 38. Lantern diffuser. 39. Lamp plugs. 41. Three-color diffuser. 43. Lamp A12-21-3 reversing light. 44. Lamp A12-21-3 direction indicator. 45. Lamp A12-21 + 5 brake signal and side light. 46. Reflector. 47. Headlights. 48. Fuse box. 49. Relay for turning on the dipped headlights. 50. 8 A fuse to protect the fog light circuits. 51. Ignition switch. 52. Fog light switch. 53. Rear fog light. 54. Control lamp high beam headlights. 55. Outdoor lighting switch. 56. Headlight switch. 57. Relay for switching on high beam headlights.

Headlights

On cars «Oka» headlights 42.3711 are used to illuminate the road at night. The design of the headlights provides an asymmetric dipped headlight beam that meets the requirements of UNECE regulations (United Nations Economic Commission for Europe). Each headlight crumbles to the front of the body with four screws 8.

The dipped and main beams are switched by the lower left lever of the three-lever switch 56 mounted on the steering column. Voltage is supplied to it when the key switch 55 outdoor lighting is fully pressed. In addition, it is possible to briefly turn on the high beam headlights (light signaling) when pulling the switch lever 56 towards you at any position of the switch key 55. This is ensured by the fact that the voltage to the light signaling contacts of the switch 56 is supplied directly from the power sources, bypassing the outdoor lighting switch.

The filaments of two headlight bulbs consume a fairly significant current - about 8... 10 A. Therefore, in order to unload the contacts of the headlight switch and increase its durability, the headlights are switched on not directly by switch 56, but through additional relays 49 and 57 of type 113.3747-10. They have powerful contacts and are installed in the cabin on a bracket near the fuse box. Relay 49 turns on the dipped beam in both headlights, and relay 57 turns on the high beam. As a result, only the supply current of the turnip windings flows through the contacts of the switch 56, not exceeding 0.2 A.

The headlight has a plastic housing 9, made in the form of a frame. To increase the strength of the case, a steel bracket is attached to the top of the case 6 Front to the case at three points (two below and one above) attached optical element. At the bottom, it rests on the heads of the adjusting screws 12, and at the top, with a spring 1, it is attracted to the socket of the lever 3. The optical element is non-separable, consists of a reflector 11 and a diffuser 14 attached to it. with lamp 10 dimensional light. On the flange of the lamp 5 there are protrusions that fit into the corresponding grooves of the reflector. Therefore, the lamp is installed in it in a strictly defined position.

Reflector 11 headlights - steel rectangular. Its reflective surface has the shape of a paraboloid of large diameter, bounded above and below by horizontal planes. The paraboloid concentrates the reflected rays of light into a beam, directing it along its axis if the pampa filament is at the focus of the paraboloid. Due to the increased horizontal diameter, the rectangular reflector provides large angles of dispersion of the light flux in the horizontal direction. Therefore, in the low beam, the right side of the road is better illuminated and the luminous flux in the direction of the eyes of drivers of oncoming vehicles is reduced, which increases traffic safety. To create a mirror surface, the reflective surface of the reflector is coated with varnish and then with a thin layer of aluminum. Such a coating reflects up to 90% of the light falling on it.

The diffuser 14 is made of colorless glass with a high degree of transparency. Its outer surface is smooth, and on the inner there is a system of prisms and lenses that turn parts of the light beam in a horizontal direction and concentrate the light flux at the most critical points of the road.

Lamp 5 of the headlight is halogen, in its flask there are iodine vapors. Halogen lamps have a high luminous efficacy and are almost twice as long as conventional lamps. In addition, the luminous efficiency of halogen lamps decreases little over time, since they do not have tungsten deposition on the inner walls of the lamp bulb and it does not darken. The process that occurs in a halogen lamp is as follows. When the lamp burns, tungsten microparticles evaporate from the filament and deposit on the walls of the lamp. Iodine vapor comes into contact with this precipitated tungsten, and at a temperature of about 600°C, tungsten iodide is formed. This compound is unstable at high temperatures and, getting into the hot filament zone, decomposes into iodine and tungsten, which is deposited on the filament, and iodine moves to the walls of the flask. Thus, when the lamp is switched on, there is a constant transfer of tungsten from the walls to the filament. Therefore, the walls of the flask remain clean, the thread thins more slowly and the durability of the pampa increases.

When replacing halogen lamps, care must be taken to handle the lamp with gloves or a handkerchief so as not to leave greasy fingerprints on the lamp glass. If there are such traces on the pump, then you need to remove them with alcohol. Grease stains cause the lamp glass to darken as it heats up to high temperatures. As a result, the light output of the lamp decreases, it overheats and fails faster.

There are two tungsten filaments in the lamp: one (55 W) for dipped beam and other (60 W) for far. The high beam filament is at the focus of the reflector, and therefore the high beam beams are collected in a narrow beam, directed almost parallel to the road and well illuminating it at the maximum distance from the car. The dipped beam thread is brought forward from the focus of the reflector and is closed from below by a special metal screen. This is done in order to limit the propagation of low beam upwards.

If you direct a beam of low beam at the wall, then the spot of light will have the shape of an ellipse with a cut off upper half. In the left part of the spot, the upper boundary of the illuminated area will pass exactly along the horizontal axis of the ellipse, and in the right part, along the line extending upward from the center of the ellipse at an angle of 15°to its horizontal axis. This shape of the beam of light provides good illumination of the road in front of the car (especially her right side and curb), and reduces the possibility of dazzling oncoming drivers.

The direction of the headlight beam in the vertical plane can be adjusted with screw 4, and in the horizontal plane with screw 12. There is another screw on the lower right side of the headlight, similar to screw 12. This screw, if necessary, adjusts the direction of the light beam simultaneously in the horizontal and vertical planes. When the screw 12 is rotated, the left edge of the reflector moves forward or backward, and it rotates relative to the ball heads of the holder 2 and the right lower adjusting screw. When the screw 4 is rotated, the reflector through the lever 3 rotates relative to the lower screws 12.

The headlight housing has a socket into which the set screw 7 is inserted. With this screw, you can adjust the direction of the headlight beam depending on the vehicle load. It is customary to adjust the headlights with a load of 75 kg on the driver's seat and with the head of the set screw turned counterclockwise until it stops. At full load, the rear of the car is lowered and, in order to maintain the same direction of the light beam, the head of the set screw 7 is turned clockwise to the extreme right position

Front direction indicators

On cars «Oka» two identical front direction indicators 17.3726-01 are used. They are located below the headlights and are attached to the front bumper with two screws. The pointers have a plastic case 15, to which a lamp socket 19 and a metal reflector 16 are riveted inside. The orange plastic diffuser 17 is attached to the case with two screws 20.

Side direction indicators

Side direction indicators 27.3726 (same right and left) fastened to the front fenders of the car with two elastic clips made in one piece with the body. A polyvinyl chloride seal is installed under the pointer. To remove the pointer, you must insert a screwdriver or a metal ruler between the seal and the fender from the front of the car and press the latch.

The case 23 of the pointer is plastic. A plastic orange diffuser 24 is also welded to the body by ultrasonic welding. The holder 21 of the plugs with the lamp socket is inserted into the body from the back side of the pointer.

Plafond

For car interior lighting «Oka» ceiling light 15.3714 is installed. It is attached to the car roof with two self-tapping screws. The plafond has a plastic housing 25 and a transparent plastic diffuser 28, on which a switch 30 and a plug 26 with a contact for attaching the lamp are installed. Voltage is supplied to plug 26. Plug 29 is connected directly to ground, and plug 31 is connected through switches in the door pillars. When the doors are opened, these switches close the plug 31 to ground, and the pump lights up. With the doors closed, the lamp can be turned on with the lampshade switch 30.

License plate lights

Two license plate lights 12.3717 are installed in the middle part of the rear bumper above the license plate and are attached to the bumper with two screws. In the plastic housing 40 of the lantern, two holder-plugs 39 are installed for attaching the lamp and attaching the wire ends. The colorless plastic diffuser 38 is attached to the body with a spring ledge on the body.

Rear lights

The rear lights are used to indicate the dimensions of the car at night, to indicate a turn, signaling braking, and for signaling and lighting roads when the car is reversing. The rear lights are divided into right 43 3716 and left 431 3716. The lantern is attached to the outer panel of the rear of the car at the top with a screw, and at the bottom it is hooked by the protrusion of its body to the edge of the socket in the body.

The body 42 of the lamp is made of metallized plastic and is divided into four chambers by partitions. In the upper chamber there is a lamp 43 of the reversing light, below it is a lamp 44 of the direction indicator, and at the bottom there is a two-filament pump 45 of the brake signal (thread 21 W) and side light (filament 5W). A plastic three-color diffuser 41 is welded to the body: red - in the zone of the brake signal chambers (and side light), orange - in the area of the turn signal camera and colorless - in the area of the reversing light camera. In the lower part, a reflector 46 is welded to the diffuser - a light-signal type device that reflects the light falling on it.

Rear fog lamp

On car parts «Oka» a rear fog lamp 2412.3716 is installed. It is attached to the lower left side of the rear bumper with two screws. Housing 33 and diffuser 36 are made of plastic and are connected with two screws. A lamp holder 35 and a mounting bracket 32 are riveted to the body.

The rear fog light is switched on by switch 52 located on the instrument panel. Voltage is supplied to it when the key of the outdoor lighting switch 55 is fully pressed, i.e. when the headlights are on.