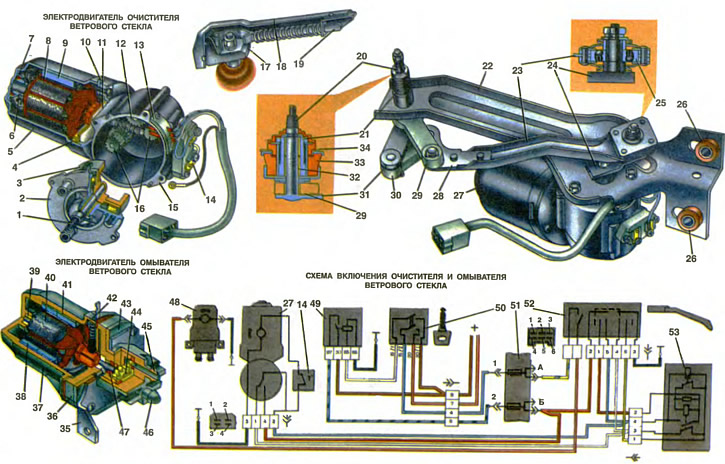

1. Gearmotor output shaft. 2. Lid. 3. Driven gear. 4, 42. Brush holder. 5, 37. Motor housing. 6, 39. Armature shaft sleeve. 7, Felt ring. 8, 40. Anchor. 9. 38. Permanent magnet. 10. Reducer mounting plate. 11. Traverse. 12. Intermediate gear. 13. Block with limit switch contacts. 14. Thermal bimetallic fuse. 15. Gear case. 16. Gear block. 17. Brush arm base. 18. Brush lever. 19. Lever stem. 20. The axis of the lever. 21. Lever axle fitting. 22. Cleaner drive bracket. 23. Intermediate lever. 24. Crank. 25. Ball bearing. 26. Rubber bushing. 27. Windshield wiper motor. 28. The tip of the intermediate lever. 29. Swinging arm. 30. Connecting rod. 31. Lever fixed on the axis 20. 32. Bushing of the lever axis. 33. Rubber bushing. 34. Windshield frame panel. 35. An arm of fastening of the electric motor. 36. Pump housing. 41. External magnetic circuit. 43. Pump cover. 44. Drive gear. 45. Suction pipe. 46. Discharge pipe. 47. Oil seal. 48. Windshield washer motor. 49. Ignition relay. 50. Ignition switch. 51. Fuse box. 52. Windshield wiper and washer switch. 53. Windshield wiper relay.

I. The numbering order of the plugs in the blocks of the gearmotor and the windshield wiper relay

II. The numbering order of the plugs in the windshield wiper switch block

On cars «Oka» an electric single-brush windscreen cleaner type 45.5205 is installed. It has two modes of operation: continuous and intermittent, which are provided using the RS-514 relay.

The wiper drive is located under the hood in front of the windshield and is fixed at three points. The arm 22 of the drive is attached with nuts to the bulkhead shield, and the fitting 21 of the lever axle is attached with a nut to the frame panel of the wind window. For cushioning, rubber bushings 26 are installed in the mounting holes of the bracket 22, and the panel 34 of the wind window frame is sandwiched between two rubber bushings - the lower 33 and the upper one.

The cleaner consists of an electric motor 27 with a gearbox, a crank mechanism and a brush with a lever. The crank mechanism is used to convert the rotational movement of the gearbox shaft into the rocking movement of the brush. The crank 24, mounted on the shaft of the gearbox, when rotating through the intermediate lever 23, rotates the lever 29, the second end of which rotates on the axis 20. The tip 28 of the lever 23 through the connecting rod 30 is connected to the lever 31, welded to the axis 20. Thus, the rocking movement of the lever 31 communicates not directly from the lever 23, but through the connecting rod 30. This design of the mechanism provides a larger swing angle of the lever 31. If the swing angle of the lever 29 is approximately 90°, then the lever 31 rotates 122°, which allows you to increase the windshield cleaning area.

The axle 20 of the brush lever rotates in two ceramic-metal bushings pressed into the fitting 21, welded to the bracket 22. The bushings 32 of the axle are saturated with oil, and therefore this unit does not need to be lubricated during vehicle operation.

The lever 23 is connected to the crank 24 by means of a double-row spherical ball bearing 25. Such a bearing allows the mechanism to work reliably with some non-parallelism between the crank and the lever. The lubricant embedded in the bearing is sufficient for the entire service life of the vehicle.

The cleaner brush is made of a pressed rubber band with a special profile. The rubber band is fixed in flexible metal holders mounted on plastic fittings, which are attached to lever 18 with a locking leash. In order for the brushes to clean the curved windshield well, they must be pressed tightly against the glass. This is ensured by a spring mounted on rod 19. Since the axis of rotation of the rod is located above the axis of rotation of the lever, the spring creates a torque that presses the brushes against the glass with a force of 6.3... 8.7 N (630...870 gs).

Windshield wiper motor

Technical specifications:

- Cleaner gearbox shaft speed at 14 V motor supply voltage, load torque 1.47 Nm (0.15 kgf·m) and ambient temperature 25±10°C, min-1, not less — 50

- Current consumption at the above load moment, A, no more than - 3.5

The cleaner motor combines an electric motor and a gearbox in one unit. Electric motor - direct current, two-pole, two-brush, with excitation from permanent magnets. It has a steel case 5, stamped in the form of a glass. Inside the case, two permanent magnets 9, having the shape of semirings, are fixed with spring holders riveted to the walls of the case. The magnets are magnetized in such a way that they have opposite poles facing inside the body. These magnets, together with the housing, form the stator of the electric motor.

Anchor 8 of the electric motor consists of a shaft, a core and a collector. The steel armature shaft has a longitudinal knurling in the middle part, and a single-thread worm at the front end. A core made of electrical steel plates is pressed onto the knurled part of the shaft. In the grooves of the core, insulated with cardboard, the armature winding is laid, the conclusions of the sections of which are soldered to the collector copper plates. The collector has a plastic base and is pressed onto the shaft from the side of the worm.

The armature shaft rotates in a ball bearing pressed into the crankcase 15 of the gearbox, and a ceramic-metal bushing 6 of the housing. The outer surface of the bushing is spherical, which allows it to self-align in the housing seat. A felt ring 7 is placed around the bushing. The bushing and felt are impregnated with oil. The ball bearing is also filled with grease. Therefore, lubrication of the motor during maintenance is not required. The axial force acting on the armature shaft is perceived by a ball bearing, which is mounted on the armature shaft between two lock washers.

The body of the electric motor is closed by the gearbox housing 15, which acts as a cover for the electric motor. The gearbox housing is cast from light alloy and is attached to the motor housing with two screws. From the electric motor side, a traverse 11 with two brush holders is riveted to the gearbox housing.

In the crankcase 15 are the gear wheels of the gearbox. The rotation from the worm is transmitted to the block of two gears 16 and the intermediate gear 12, from which, in turn, the second block of gears 16 rotates. The upper gears transmit rotation to the driven gear 3 with internal gearing, mounted on the output shaft 1 of the gearbox. This shaft rotates in a ceramic-metal oil-impregnated bush pressed into cover 2. The gear ratio is 1:75.

A plastic block 13 with three spring contacts of a limit switch is fixed on the gearbox housing from the outside, which, when the cleaner is turned off, stops the electric motor at the moment when the cleaner brush is in its lowest position. The switch contacts are pressed against a figured annular brass plate on gear 3. To protect the electric motor from overloads in case of brush freezing to glass, as well as in case of high resistance to brush movement or jamming in the cleaner mechanism, a reusable thermobimetallic fuse 14 is installed on the gearbox housing.

Windshield Wiper Motor Operation

The cleaner is activated by the right lever of the three-lever switch if the ignition is on. The lever has three positions: initial upper (purifier off), average (purifier intermittent operation enabled) and extreme lower (continuous cleaner operation).

Intermittent operation is provided by relay 53 type RS-514. Current comes from the output «plus» battery or clip «30» generator through contacts «87» and «30» ignition relay 49 to switch 52. Then current flows through the red wire to the plug «2» relay and, further, through the relay winding. It works, closes the upper (on the image) relay contacts and current is supplied to the plug through the blue wire «2» cleaner. The cleaner is working.

At the same time, current flows through the breaker winding in relay 53 (in the picture above). This current heats up the breaker coil. The bimetallic plate of the breaker bends from heating, and the breaker contacts open, turning off the power to the relay winding. The relay armature returns to its original position, and the upper (on the image) relay contacts open. The cleaner motor stops.

Since the current no longer flows through the breaker winding, it cools down along with the bimetallic strip. The plate takes its former shape, and the breaker contacts are closed, including the power supply of the turnip winding. The purifier turns on again. The described cycle repeats again with a frequency of 9...17 times per minute.

During one cycle, the brush makes one double stroke and stops in the lowest position. At the initial moment of turning on the cleaner for intermittent operation (the bimetallic breaker plate has not yet heated up) the brushes can make up to four continuous double strokes.

Continuous operation of the purifier. Current comes from the plug «5» switch 52 on the blue wire to the plug «2» cleaner motor. The cleaner runs at a constant speed, and the brush swings at a frequency of 50...60 cycles per minute.

The cleaner is turned off after the switch lever 52 is returned to its original position. In this case, the current to the motor armature winding is supplied from the plug «B» fuse block 51 through the closed contacts of the limit switch of the electric motor. At the moment when the cleaner brush comes to the lower position, the limit switch contacts will open and the power of the armature winding will be turned off. The armature of the cleaner motor will stop and the brush will remain in the down position.

Windshield washer motor

The electric motor, combined with the washer pump, is mounted in the engine compartment on a bracket attached to the right wheel mudguard. The pump motor is two-pole, two-brush, with excitation from permanent magnets. A steel ring 41 with a magnet 38, made up of two identical rings, is installed in the plastic case 37. The steel ring is the outer magnetic circuit and serves to amplify the magnetic field of the magnet. The armature shaft rotates in two ceramic-metal bushings 39 impregnated with oil. The brush holders 42 are made in one piece with the power supply plugs and are fastened with two screws to the pump housing 36.

On the housing 37 of the electric motor, a plastic housing 36 of the pump and a cover 43 are fixed. All these parts are pulled together by four screws through a steel bracket 35 for mounting the electric motor. The washer pump consists of a pair of gear wheels made of bronze. The driving gear wheel 44 is mounted on the motor shaft and fixed on it with a pin key. The driven gear rotates freely on an axle pressed into the pump housing. A rubber gasket is installed between the casing and the cover of the pump. The output end of the armature shaft is sealed with a rubber gland 47 installed in the pump casing.

The washer motor is switched on when the ignition is on by the right lever of the three-lever switch 52. To do this, the lever is pulled towards itself (non-fixed lever position). In the switch diagram 52, the washer switch is shown on the left. The current for powering the electric motor is supplied from the plug «A» fuse box.