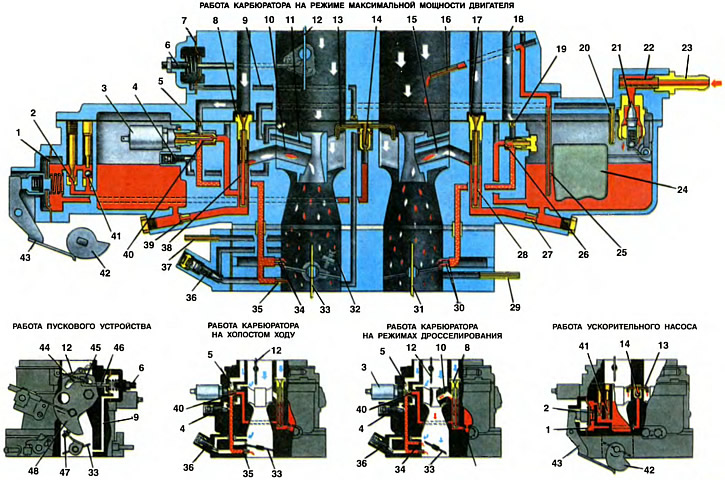

1. Accelerator pump diaphragm. 2. Bypass jet of the accelerator pump. 3. Solenoid shut-off valve. 4. Adjusting screw for additional air of the factory adjustment of the idling system. 5. Air jet idling. 6. Trigger adjusting screw. 7. Launcher aperture. 8. The main air jet of the first chamber. 9. Air channel of the starting device into the throttle space. 10. Atomizer of the main dosing system of the first chamber. 11. Inertial economizer atomizer. 12. Air damper. 13. Accelerator pump sprayer. 14. Accelerator pump spray valve. 15. Atomizer of the main dosing system of the second chamber. 16. Econostat atomizer. 17. The main air jet of the second chamber. 18. Float chamber balancing channel. 19. Air jet of the transition system of the second chamber. 20. A tube with a fuel jet of an inertial economizer. 21. Needle valve. 22. Fuel filter. 23. Fuel supply pipe. 24. Float. 25. Tube with econostat fuel jet. 26. Fuel jet of the transition system of the second chamber. 27. The main fuel jet of the second chamber. 28. Emulsion tube of the second chamber. 29. Pipe suction of crankcase gases into the throttle space of the carburetor. 30. Outlets of the transition system of the second chamber. 31. Throttle valve of the second chamber. 32. Adjusting screw for the amount of idle mixture. 33. Throttle valve of the first chamber. 34. Outlets of the transition system of the first chamber. 35. The outlet of the idle system. 36. Quality adjusting screw (composition) idle mixture. 37. Vacuum intake manifold of the vacuum ignition timing regulator. 38. Emulsion tube of the first chamber. 39. The main fuel jet of the first chamber. 40. Fuel jet idling. 41. Check ball valve accelerator pump. 42. Accelerator pump drive cam. 43. Accelerator pump drive lever. 44. Choke lever pin, included in the groove of the lever. 45. The pin of the lever of the air damper acting from the rod 46. 46. The rod of the starting device. 47. Adjusting screw for slightly opening the throttle valve of the first chamber. 48. Choke control lever.

Carburetor operation when starting and warming up a cold engine

Due to the low temperature of engine parts and the low speed of air movement through the carburetor, mixture formation is significantly impaired. Reliable starting of the engine requires a strong enrichment of the mixture, which is provided by the carburetor starting device.

When starting a cold engine, the choke control handle 12 is pulled out to the stop. At the same time, the throttle control pedal must not be touched in order to avoid supplying an uncontrolled excess portion of fuel to the engine. Under the influence of thrust, the air damper control lever 48 rotates clockwise, as a result of which the pin 44 of the air damper lever is released, and the spring of the air damper lever closes it. the required size.

When the crankshaft of the engine is rotated by the starter, the resulting vacuum behind the air damper is transmitted to the holes and channels of the idle system, and through the ajar throttle valve 33 to the atomizer 10 of the main metering system. Under the action of vacuum, the fuel begins to intensively flow out of the hole 35 of the idle system and the atomizer 10, providing the necessary enrichment of the combustible mixture.

The axis of the air damper is displaced, therefore, after starting the engine and increasing the engine speed, the damper will be slightly opened by the air flow, stretching the spring of the damper lever, which prevents excessive re-enrichment of the combustible mixture. The amount of opening of the air damper will be limited by the width of the lever groove 48, in which the pin of the air damper lever is located

The vacuum from the throttle space is transmitted through the air channel 9 to the working cavity of the diaphragm 7 of the starting device. When cranking the crankshaft with a starter at the initial moment, the vacuum is small, it is not able to overcome the resistance of the diaphragm spring, which remains stationary. After starting the engine (the appearance of stable flares and an increase in the frequency of rotation) the vacuum increases sharply, under its action the diaphragm 7 with the rod 46 is retracted and the rod behind the pin 45 slightly opens the air damper. The extreme retracted position of the diaphragm 7 is limited by the adjusting screw 6. The limiting position of the adjusting screw is set when the air damper 12 is fully closed by turning the lever 48. In this position of the lever, manually press the stem 46 until it stops, the air damper should open at the same time by 2.2 mm (a gap that is checked between the wall of the inlet neck of the carburetor cover and the edge of the air damper on the side opposite to the displacement of the damper axis). If necessary, the gap is adjusted by screw 6.

The carburetor starter allows the choke to open or close automatically, preventing excessive enrichment or depletion of the combustible mixture.

As the engine warms up, the air damper is fully opened, gradually returning the damper control handle to its original position.

The starting device of the carburetor provides a reliable start of a serviceable and properly adjusted engine without any preliminary preparation to a temperature of minus 25°C.

Carburetor operation at idle

Stable idling is provided by the idling system. In modern carburetors, this system also corrects the composition of the combustible mixture in all engine operating modes.

Throttle valves at idle are covered, air - open. The outlets 34 of the transition system of the first chamber are located above the upper edge of the throttle valve. The vacuum from under the throttle valve 33 through the outlet 35 is transmitted to the idle fuel jet 40. Under the action of vacuum, the fuel entering the emulsion well from the float chamber through the main fuel jet 39 rises to the jet 40, mixes with the air entering through the air jet 5, passes jet 40 in the form of an emulsion and then down the emulsion channel, where air is additionally mixed, coming through the outlet holes 34 and from under the adjusting screw 36, and the emulsion exits through the hole 35 into the engine intake pipe. The fuel level in the emulsion well decreases and becomes less than the fuel level in the float chamber. The difference in levels creates a pressure, under the influence of which, in this case, the fuel flows through the main fuel jet 39.

In this mode, the vacuum in the small diffuser at the atomizer 10 of the main metering system is insignificant and no fuel flows through it.

When the ignition is turned off, power is removed from the electromagnetic shut-off valve 3, the hole of the jet 40 is blocked by the valve needle, interrupting the flow of fuel and preventing the engine from self-ignition from overheating.

When the engine operation switches to throttling modes, when the throttle valve of the first chamber begins to open, the transition system of the first chamber is switched on, which includes holes 34, jets and channels of the idle system. When the edge of the throttle valve 33 is above or at the level of the holes 34, the emulsion will flow both from the hole 35 and through the outlet holes 34. This ensures a smooth transition to throttling modes. Engine idle control is carried out at car service stations with measurement of carbon monoxide content (SO) in exhaust gases. Regulation is carried out by adjusting screw 36 quality (composition) mixture and screw 32 of the amount of the mixture.

Since 1998, the carburetor idle system has been slightly changed. Previously, additional air was supplied to the adjusting screw 36 through the channel from the over-throttle space (as shown here in the picture), and now this channel is connected to the line of outlets 34 of the transition system. Thus, now the screw 36 regulates the supply of the fuel emulsion. Turning the screw clockwise leans the mixture, and counterclockwise enriches it.

Carburetor operation in throttling modes

In throttling modes, the first chamber mainly works, which ensures the operation of the engine in a wide range. The required composition of the mixture is ensured by the joint operation of the main dosing system and the idle system. When the throttle valve 33 is opened, the vacuum in the atomizer 10 increases, the fuel in the emulsion well begins to rise, is captured by air entering the emulsion tube 38 through the main air jet 8 of the main metering system, and is carried into the atomizer. From this moment, the joint work of the above systems begins.

After the throttle valve 33 opens to 2/3 of the full angle of rotation, the throttle valve 31 of the second chamber begins to open. Both throttle valves come to the fully open position at the same time.

The main dosing system of the second chamber operates similarly to the first one. The absence of dips in the operation of the engine at the beginning of the opening of the throttle valve 31 is ensured by the operation of the transition system of the second chamber. At the moment when the throttle valve 31 starts to open, the outlet openings 30 of the system are under vacuum. In this case, fuel begins to flow through the jet 26, mix with air from the jet 19 and flow out in the form of an emulsion through the outlets 30 of the transition system.

Carburetor operation at full load (throttle valves are fully open)

The main dosing systems, the idling system, transitional systems, as well as when the required vacuum is reached, and the econostat work. Due to some decrease in vacuum in the channels of the idle system and transitional systems with fully open dampers 31 and 33, the outflow of fuel from these systems is insignificant.

When a sufficient vacuum is reached at the atomizer 16 of the econostat, the econostat comes into operation, enriching the combustible mixture at full load. The fuel from the float chamber enters through a tube 25 with a jet and atomizer 16 into the air stream.

Accelerator pump operation

To enrich the combustible mixture in the vehicle acceleration mode, the accelerator pump injects additional portions of fuel into the first and second mixing chambers. With a sharp increase in load (throttle valve opens abruptly) cam 42 on the axis of the damper 33 acts on the lever 43, which compresses the spring in the telescopic cup of the diaphragm 1. Expanding, the spring moves the diaphragm, providing a smooth prolonged injection of fuel through the valve 14 and sprayers 13 into both mixing chambers.

With a smooth opening of the damper, the fuel is transferred through the bypass jet 2 back to the float chamber.

Operation of the inertial economizer

The economizer does not allow depletion of the combustible mixture during a sharp left turn of the car, which eliminates the failure or interruption of the engine.

The float chamber is made on the right side of the carburetor, and in cases of a sharp left turn of the car, the fuel in the float chamber is shifted to the right side, opposite to the holes that feed the main fuel jets 27 and 39, resulting in engine failure or interruptions due to lean mixture.

With a sharp left turn of the car, tube 20 with the economizer fuel jet is flooded.

Due to the rarefaction in the atomizer 11, the fuel will enter it from the float chamber through the fuel nozzle of the tube 20 through the fuel channel into the first mixing chamber, enriching the combustible mixture.