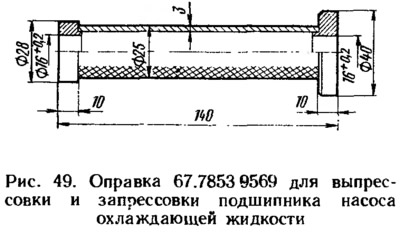

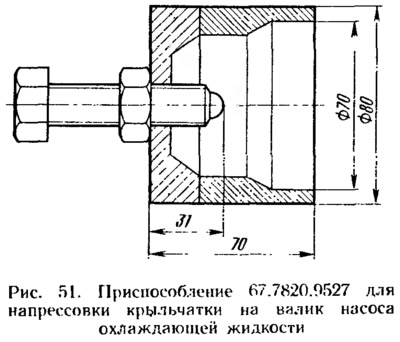

When assembling the pump using mandrel 67.7853.9568 (pic. 50) install the stuffing box without distortions in the pump housing. With mandrel 67.7853.9569 (see fig. 49) press the roller with the bearing so that the seat of the locking screw 1 (see fig. 10) aligned with the hole in the pump housing. The bearing lock screw is screwed in and the contours of the socket are caulked to prevent loosening of the screw. Then using tool 67.7820.9527 (pic. 51) press the impeller 4 (see fig. 10) and toothed pulley 9, bearing dimensions (52±0,5) mm and (39,8±0,1) mm indicated on rice. 10. Before pressing the pulley, it is heated to 150-200°C. After the pulley has cooled, the pump is attached to the impeller and the reliability of the pulley connection on the roller is checked by applying a torque of 24.5 N·m to the pulley. The pulley must not rotate.