Install the car on a lift or inspection ditch and slow it down with a parking brake. Disconnect the wire from the terminal «minus» battery and remove the spare wheel. Raise the car, remove the engine mudguards and drain the coolant from the radiator and cylinder block, for which the heater tap is opened, the drain plugs on the radiator and cylinder block are unscrewed (just two plugs) and remove the expansion tank cap. Remove the clamp of the intake pipe of the mufflers and disconnect it from the muffler pipe by unscrewing the bolts tightening the pipe flanges.

Lower the car and remove the air filter by disconnecting the crankcase ventilation hoses from the cylinder head cover and from the carburetor, as well as the warm air supply hose from the air filter thermostat. Close the carburetor with a technological plug.

Disconnect the wires from the spark torque sensor, from the carburetor and from the coolant temperature indicator sensor. Remove high voltage wires.

The clamps are loosened and the hoses leading to the radiator, to the coolant pump and to the expansion tank are disconnected from the thermostat, and the heater radiator supply hose is disconnected from the heater pipe on the front end. The fuel supply hose is disconnected from the fuel pump, and the coolant outlet hose and the vacuum extraction hose to the vacuum brake booster are disconnected from the intake pipe.

Disconnect the carburetor throttle and air damper cables from the engine. Having unscrewed the fastening nuts, disconnect the exhaust pipe of the mufflers from the cylinder head.

Remove the windshield washer reservoir, and then the front toothed belt guard and cylinder head cover.

Set the gear lever to the neutral position so that the mark on the camshaft pulley is against the alignment mark on the rear toothed belt cover (pic. 20). This operation is necessary in order to correctly position the camshaft pulley in relation to the crankshaft when installing the cylinder head on the engine.

Loosen the axle nut 7 (see fig. 7) tension roller and remove the axle together with the roller and spacer. Then remove the belt from the camshaft pulley.

Holding the camshaft pulley from turning with fixture 67.7811.9513 or some lever with grippers for the pulley holes, unscrew the mounting bolt and remove the pulley with the key.

Loosen the nuts securing the alternator to the tension bar and the front engine mount bracket and disconnect the tension bar from the cylinder head.

Unscrew the nut securing the rear cover of the toothed belt to the cylinder head and the bolt securing the cover to the cylinder block. Unscrew the mounting bolts and remove the head assembly with the carburetor, fuel pump and spark moment sensor. Remove the cylinder head gasket from the block.

Install the cylinder head in the reverse order, following the recommendations set out in Sec. «Engine assembly». The gasket between the head and the cylinder block cannot be reused, so replace it with a new one.

If the cylinder head bolts are loose (bolt shaft length exceeds 135.5 mm), then they are replaced with new ones. Lubricate the threads and bolt heads in advance by dipping them in engine oil and allowing excess oil to drain. In addition, remove oil from the holes (if it got there) under the bolts in the cylinder block.

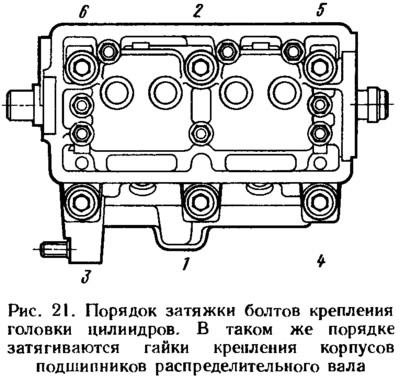

Bolts are tightened in a certain sequence (pic. 21). To ensure a reliable seal and eliminate the tightening of the bolts during vehicle maintenance, the cylinder head bolts are tightened in four steps:

- 1st reception - a moment of 19.6 N·m;

- 2nd reception - a moment of 69.6-85.3 N·m;

- 3rd reception - turn the bolts 90°;

- 4th reception - again tighten all the bolts by 90°.

After installing the cylinder head, check and adjust the clearance in the valve mechanism, the tension of the camshaft and generator drive belts, the carburetor drive and the ignition timing.