Air is supplied to the engine cylinders through the air filter, carburetor and intake pipe.

Exhaust gases are released into the atmosphere through the exhaust manifold, exhaust pipe, additional and main mufflers.

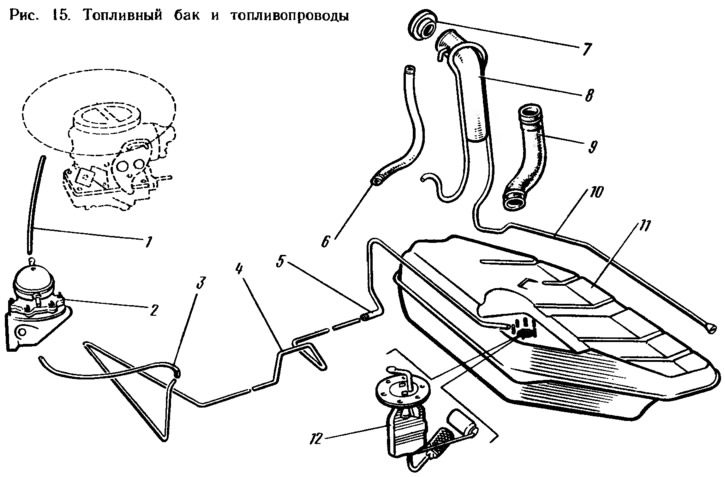

Fuel tank

Stamped, welded, consists of two stamped steel semi-hulls. The tank is connected to the atmosphere by a ventilation hose 10. The filling pipe 8 is connected by a hose 9 to the tank branch pipe, closed from above with a blind screw plug 7. A fuel level sensor 12 is installed on top of the tank.

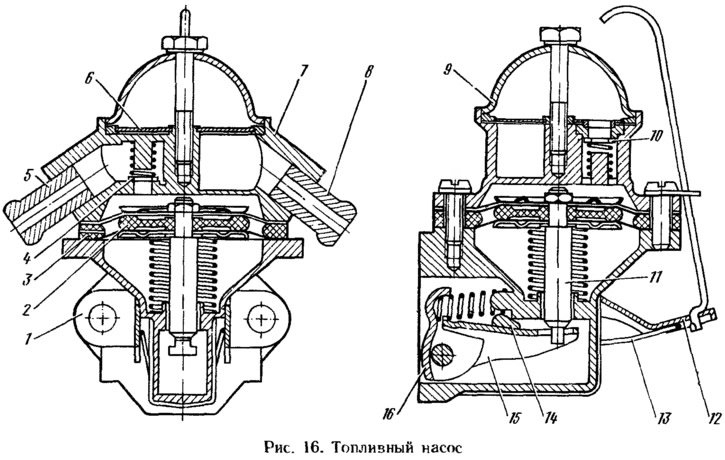

Fuel pump

Diaphragm type, mechanically driven, equipped with lever 12 (pic. 16) manual swap. The pump consists of a lower housing 1 with drive levers, an upper housing 7 with valves and nozzles, a diaphragm assembly and a cover 9. Three diaphragms are installed between housings 7 and 1: two upper working ones for supplying fuel, the lower one is a safety one to prevent fuel from entering the drive housing in case of damage to the working diaphragms. Between the diaphragms there are outer 3 and inner 2 spacers. The outer gasket has a hole for fuel to escape to the outside in case of damage to the working diaphragms. Diaphragms with plates are mounted on stem 11 and fastened from above with a nut. There is a compressed spring on the stem under the diaphragm assembly. The rod with an L-shaped shank is inserted into the slot of the balancer 15 and allows, without disassembling, to remove the diaphragm assembly. In the lower case, levers 12, 16 and a balancer 15 are installed. Above the balancer is a cam 14 of the lever 12 of manual pumping, pressed by a spring 13. Inlet 10 and outlet 4 valves are installed in the upper case 7. From above, a cover 9 is attached to the pump housing with a central bolt. There is a plastic mesh filter 6 between the cover and the housing. The upper housing has a discharge 5 and suction 8 nozzles.

Air filter

Dry type filter with replaceable filter element. The filter housing is mounted on the carburetor, sealed with a rubber gasket and fastened with three brackets to the cylinder head cover studs and the carburetor bracket. The filter element is interchangeable with the filter element of the VAZ-2121 engine, made of special cardboard with a precleaner. A damper is installed in the inlet pipe of the filter housing, the position of which is fixed by a spring.

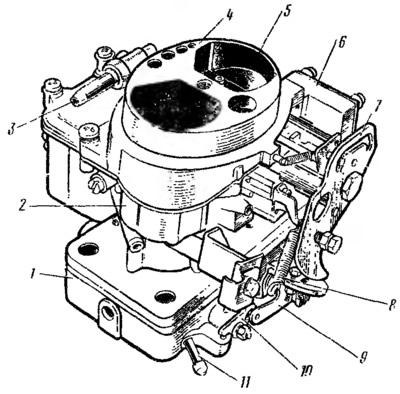

Carburetor

Models 1111-1107010 and 11113-1107010, Emulsion Type, Dual Chamber, Downflow, Sequential Throttle (pic. 17). The carburetor has a balanced float chamber, a crankcase exhaust system for the throttle valve.

Pic. 17. Carburetor 1111-1107016: 1 - throttle body; 2 - carburetor body; 3 - fuel supply pipe. 4 - carburetor cover; 5 - air damper, 6 - starting device; 7 - air damper control lever; 8 - return spring; 9 - throttle actuator lever of the second chamber: 10 - throttle lever of the second chamber; 11 - branch pipe for supplying crankcase gases to the throttle space of the carburetor.

The carburetor has two main dosing systems, a transition system and an idle system with an electromagnetic shut-off valve of the first chamber, a transition system of the second chamber, an econostat, an energy economizer, a diaphragm accelerator pump, a starting device.

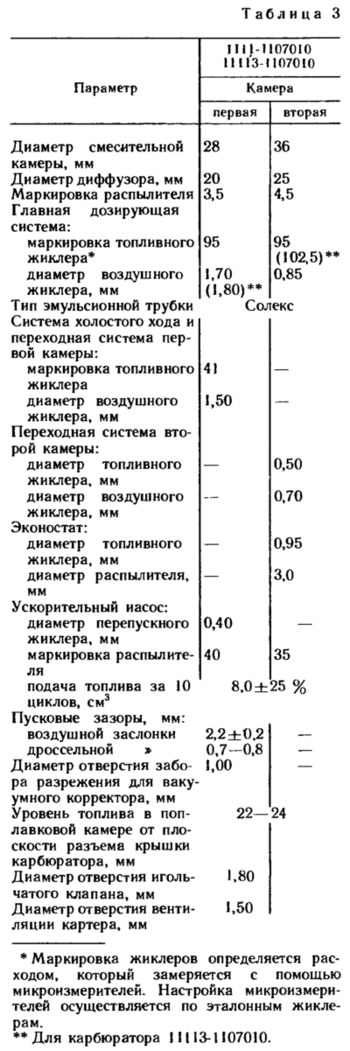

Carburettors 1111-1107010 and 11113-1107010 differ from each other only in some calibration data. The main data of carburetors are given in table. 3.

The main dosing system is powered from the float chamber, into which fuel enters through the needle valve 22 (pic. 18). Through the main fuel jets 25 and 40, the fuel enters the emulsion wells. With sufficient rarefaction in the atomizers 9 and 16 of the main metering systems, the fuel is mixed in emulsion wells with air entering through the main air jets 8 and 17, and in the form of an emulsion is sucked into the diffusers of the mixing chambers. Only the main dosing system of the first chamber operates in throttling modes. The second chamber begins to open and operate when the throttle valve 34 of the first chamber is more than two-thirds open.

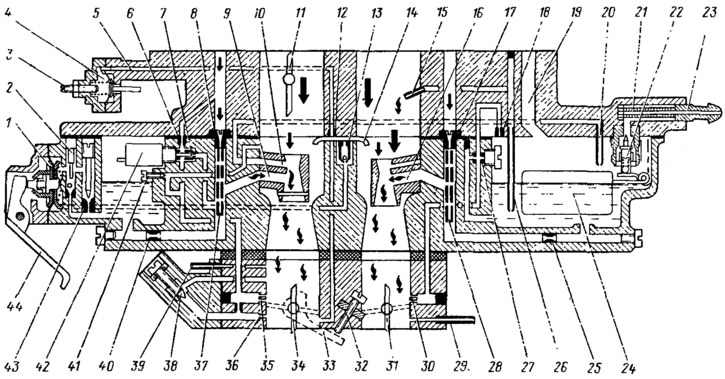

Pic. 18. Scheme of the carburetor 1111-1107010: 1 - accelerator pump diaphragm; 2 - stopper of the check valve of the accelerator pump; 3 - adjusting screw of the starting device; 4 - aperture of the starting device; 5 - air channel of the starting device; 6 - idle air jet; 7 - idle fuel jet; 8 - main air jet of the first chamber; 9 - atomizer of the main dosing system of the first chamber; 10 - inertial economizer atomizer; 11 - air damper; 12 - air jet starting device; 13 - accelerator pump spray valve; 14 - accelerator pump sprayers; 15 — econostat atomizer; 16 - atomizer of the main dosing system of the second chamber; 17 - main air jet of the second chamber; 18 - air jet of the transition system of the second chamber; 19 - balancing channel of the float chamber; 20— tube with a fuel jet of an inertial economizer; 21 - fuel filter; 22 - needle valve; 23 - fuel supply pipe; 24 - float; 25 - main fuel jet of the second chamber; 28 - a tube with a fuel jet econostat; 27 - fuel jet of the transition system of the second chamber; 28 - emulsion tube of the second chamber; 29 - branch pipe for suction of crankcase gases into the throttle space; 30 - outlet holes of the transition system of the second chamber; 31 - throttle valve of the second chamber; 32 - adjusting screw for the amount of idle mixture; 33 —throttle lever of the first chamber; 34 - throttle valve of the first chamber; 35 - outlet holes of the transition system of the first chamber; 36 - outlet of the idle system; 37 - emulsion tube of the first chamber; 38 - quality adjusting screw (composition) idle mixtures; 39 - vacuum intake pipe of the vacuum ignition timing controller; 40 - main fuel jet of the first chamber; 41 - adjusting screw for additional air for factory adjustment of the idle system; 42 - shut-off solenoid valve; 43 - bypass jet of the accelerator pump; 44 - accelerator pump drive lever.

The idle system provides the necessary composition of the combustible mixture at idle. In this case, the throttle valves 34 and 31 are closed. Fuel from the emulsion well of the main dosing system of the first chamber rises through the fuel channel, passes through the fuel jet 7, mixes with air from the air jet 6 and enters in the form of an emulsion through the outlet 36 into the throttle space. Under the screw 38 of the quality of the mixture, air is additionally sucked from the mixing chamber.

The transition system of the first chamber provides a smooth transition of the engine from idling to throttling modes. At the moment of opening the throttle valve 34 of the first chamber, the outlet holes 35 fall under vacuum, emulsion will also flow from them, ensuring smooth transitions.

When the ignition is turned off, the electromagnetic shut-off valve 42 is turned off, the needle closes the fuel jet 7 and prevents the engine from running with the ignition off.

The transition system of the second chamber ensures a smooth transition of the engine operation at the moment of opening the throttle valve 31 of the second chamber. At this moment, the outlet holes 30 fall under vacuum, the fuel from the float chamber rises up through the fuel channel, passes the fuel jet 27, mixes with air from the air jet 18 and enters in the form of an emulsion through the emulsion channel through the outlet holes 30 under the throttle valve.

The econostat enriches the combustible mixture at fully open throttle valves at speeds close to maximum. With open throttle valves, the vacuum in the mixing chambers and sprayer 15 of the econostat increases significantly. Fuel from the float chamber enters through the jet 26 of the econostat, rises up the tube and is sucked into the mixing chamber through the atomizer 15.

The inertial economizer prevents depletion of the combustible mixture during a sharp left turn of the car, when the fuel in the float chamber mixes to the right and the fuel level above the main fuel jets 25 and 40 drops significantly. With a sharp left turn, the fuel in the carburetor shifts to the right and floods the tube 20 with the fuel jet. The fuel will flow through the fuel channel through the atomizer 10 into the mixing chamber.

Accelerator pump - diaphragm type, driven by a cam on the axis of the throttle valve of the first chamber. With a sharp opening of the throttle valve, the cam presses the lever 44 and through the spring in the pusher acts on the diaphragm 1, overcoming the resistance of the return spring. The diaphragm supplies fuel through the channel through the ball valve and injects it through the nozzles 14 into the mixing chambers of the carburetor. During the reverse stroke of the diaphragm, under the action of a return spring, fuel is sucked from the float chamber through the check ball valve and bypass jet 43 into the working cavity of the accelerator pump.

The starting device ensures the preparation of a rich combustible mixture when starting a cold engine. Turning lever 8 (pic. 19) clockwise, the throttle valve 9 of the first chamber is slightly opened with the outer edge a by the adjusting screw 10. At the same time, the expanding groove between the internal profiles b and c of the lever 8 releases the pin of the lever 3 of the air damper and it will be held completely closed due to the return spring 1. The axis of the air damper 2 is displaced, therefore, after starting the engine, the air damper can be slightly opened by the air flow, stretching the spring 1, which ensures the lean mixture.

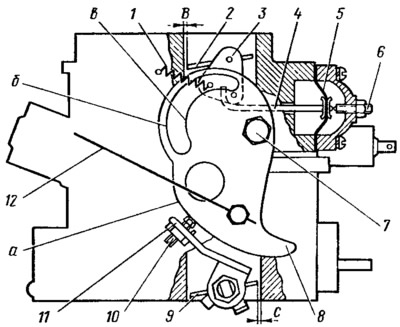

Pic. 19. Carburetor starter 1111-1107010: 1 - air damper return spring; 2 - air damper; 3 - air damper lever; 4 - diaphragm rod; 5 - diaphragm; 6 - adjusting screw; 7 - axis of the air damper control lever; 8 - air damper control lever; 9 - throttle valve of the first chamber; 10 - adjusting screw for slightly opening the throttle valve of the first chamber; 11 - throttle lever of the first chamber; 12 — draft of the handle of a drive of the air damper; a - the edge of the lever 8 to ensure the starting clearance of the throttle valve of the first chamber; b - the upper profile of the groove of the lever 8, which provides mechanical opening of the air damper; c - the lower profile of the groove of the lever 8 to limit the maximum opening of the air damper; B - starting gap at the air damper; C - starting clearance at the throttle valve of the first chamber.

The vacuum from the throttle space acts on the diaphragm 5 and can slightly open the air damper by the stem 4. Adjusting screw 6 allows you to adjust the amount of damper opening.