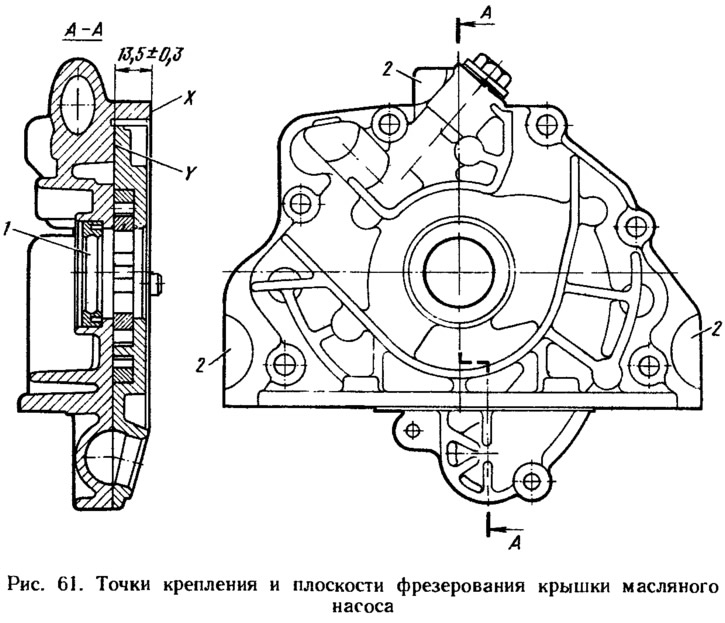

The aluminum cover in the plane of contact of the gears must not have ledges. The surface must be flat. In case of noticeable wear, clamp the cover at points 2 (pic. 61) and mill the X and Y surfaces to size (13,5±0,3) mm. The maximum metal removal should not exceed 0.2 mm. The crankshaft seal 1 is replaced with a new one. When pressing the stuffing box, the force is applied as close as possible to the outer diameter of the stuffing box.

The working surfaces of the case must not have scratches. The limiting outer diameter for the driven gear must not exceed a diameter of 75.10 mm (pic. 62). The maximum minimum segment width must be at least 3.40 mm. In case of high wear, the housing is replaced with a new one.

The indicator measures the maximum axial clearances, which should not exceed 0.12 mm for the drive gear and 0.15 mm for the driven gear.

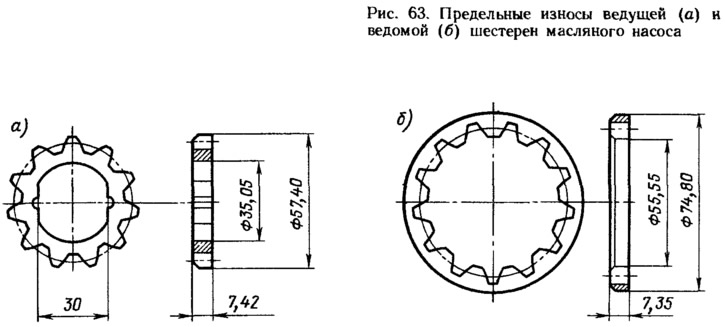

The limiting minimum dimensions of gears are shown in fig. 63. If the gaps and dimensions go beyond the limit values, the gears are replaced with new ones.

They also check whether the elasticity of the pressure reducing valve spring has decreased by comparing the obtained data with the required ones:

- The length of the spring in the free state, mm - 44.72

- Spring loaded length (39,24±2,35) N, mm - 31.70

The limiting diameters must be: reducing valve - not less than 11.98 mm; holes for the valve - no more than 12.03 mm.