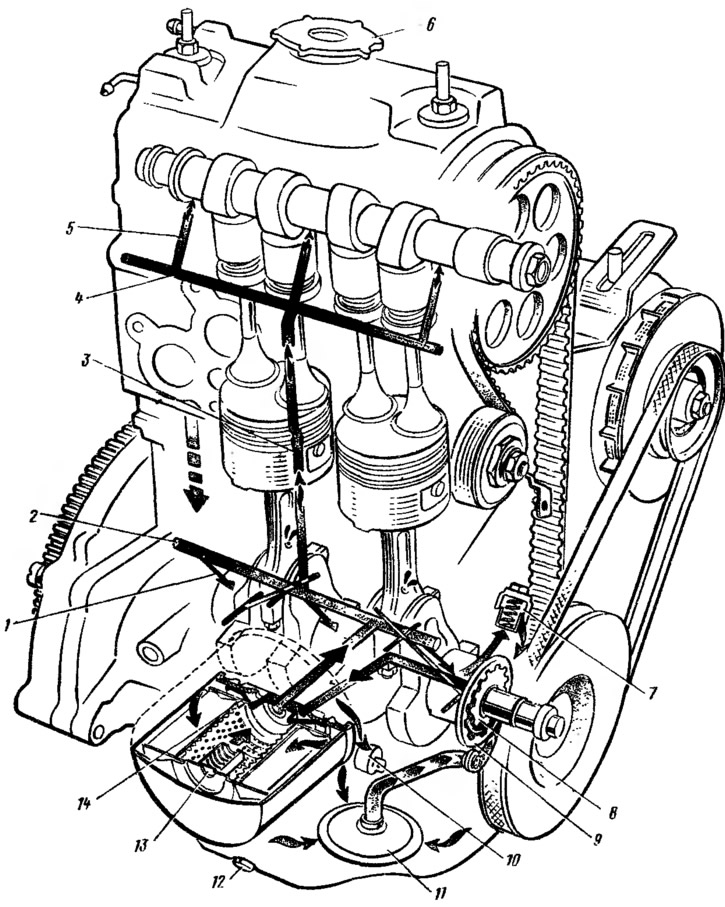

Lubrication system (pic. 12) consists of an oil pump, an oil filter, a crankcase, an oil filler neck on the cylinder head cover, an oil level indicator in the crankcase, as well as channels in the block and cylinder head. The minimum oil pressure in the system is controlled by sensor 10, which is screwed into the oil filter flange hole connected by a channel to the main oil line in the cylinder block. The minimum oil pressure must be at least 0.08 MPa at a crankshaft speed of 820-900 min-1. When the pressure drops below the allowable value, the control lamp of the light board lights up in red.

Pic. 12. Lubrication system: 1 - oil supply channel to the main bearing; 2 - main oil line; 3 - vertical channel in the cylinder block; 4 - oil line in the cylinder head; 5 - channel for supplying oil to the camshaft bearing journal; 6 - oil filler cap; 7 - pressure reducing valve; 8 - oil pump drive gear; 9 - driven gear of the oil pump; 10 — the gauge of a control lamp of pressure of oil; 11 - oil receiver; 12 - drain plug; 13 - oil filter bypass valve; 14 - oil filter anti-drain valve.

Oil pump

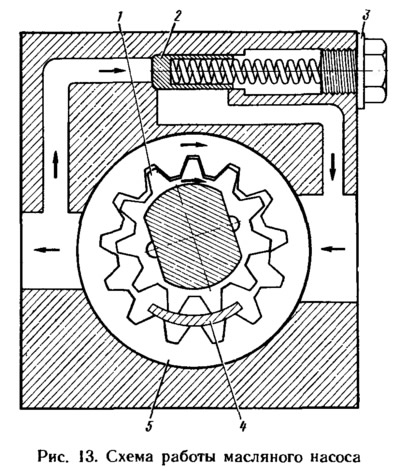

Gear, with internal gears, is located at the front end of the crankshaft. The pump consists of a cover, a housing with suction and discharge cavities and an oil receiver. Leading 1 is installed in the body (pic. 13) and driven 5 gears. To ensure the necessary clearances between the gears and the housing when the temperature changes, the housing is cast from cast iron, the gears are made from cermet. In the housing, the suction cavity is separated from the discharge cavity by a sickle-shaped protrusion 4.

presenter (with external teeth) and the driven gears of the pump suck in oil and feed it into the discharge cavity of the pump with the cavities of the teeth. At a pressure above 0.45 MPa, the pressure reducing valve 2 opens and part of the oil passes into the suction cavity of the pump.

An aluminum ring 3 is placed under the pressure reducing valve plug. The crankshaft in the pump cover is sealed with a rubber gland. The oil receiver of the pump is sealed with a rubber ring.

The oil pump is interchangeable with the VAZ-2108 engine pump.

Oil filter

Interchangeable with the oil filter of the VAZ-2105 engine. The filter is full-flow, non-separable. A filter element made of special cardboard is installed in the steel housing.

Crankcase ventilation

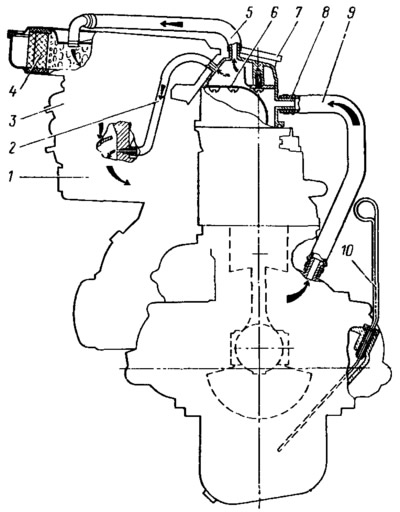

Forced, closed, not allowing the release of crankcase gases into the atmosphere. When the engine is running, crankcase gases through the lower exhaust hose 9 (pic. 14) sucked into the oil separator (cavity), which is closed with a cover 6. Further, the crankcase gases are sucked in through the upper exhaust hose 5 and the crankcase gases outlet hose 2 and enter the combustion chambers of the engine with a combustible mixture.

Pic. 14. Engine crankcase ventilation scheme: 1 - inlet pipe; 2 - hose for removal of crankcase gases into the throttle space of the carburetor; 3 - carburetor; 4 - air filter element; 5 - top exhaust hose; 6 - oil separator cover; 7 - oil filler cap; 8 - branch pipe of the exhaust hose; 9 - lower exhaust hose; 10 - oil level indicator.