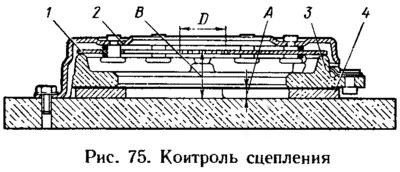

Before checking the condition of the leading part of the clutch, make sure that the working surface of the pressure plate is not damaged (no ring wear, deep scratches and other defects). Then install cover 2 (pic. 75) clutch assembly with pressure plate 3 on a device with an intermediate ring 4 with a thickness of A \u003d 8.1 mm. This device simulates a flywheel with a driven disk.

Having fixed the clutch cover, perform three clutch release strokes within 5.7-6.7 mm, applying a load to the petals of the pressure spring 1 on a diameter of 34 mm. At the same time, the amount of withdrawal of the pressure disk is measured. Shutdown progress (5,7±0,1) mm must correspond to a pressure plate offset of at least 1.2 mm. Measure the distance B from the base of the fixture to the plane of the ends of the pressure spring petals. It should be between 27.5-30.5 mm for a new clutch. In the process of clutch operation due to wear of the discs, this size increases.

If the discs are worn, then repeat the above operations using an intermediate ring with a thickness of A = 6.5 mm. Shutdown progress (5,7±0,1) mm must correspond to a pressure plate offset of at least 1.2 mm. Distance B must be no more than 37 mm.

If the offset of the pressure plate in both cases is less than 1.2 mm, replace the clutch cover assembly.

Check the condition of the cable. First of all, they are convinced of the free, without jamming, movement of the cable, that there are no damages to the coatings of the cable and sheath, that there are no breaks in the cable and sheath. They check the fastening and condition of the cable ends and the sheath, the anti-friction tube, which should protrude from both ends of the cable and the sheath and not be free to move by hand. Check the condition of the leash and protective caps. When the cable or sheath is worn, when the cable coating is chafed or the sheath coating is significantly damaged, the cable is replaced. If the leash and protective caps are worn or damaged, replace them. Check the condition of the plastic sleeve in the upper end of the cable, if necessary, replace it.

Check the elasticity of the springs. Clutch and brake pedal springs are interchangeable. The length of the spring must be: under force (13±2) N—80 mm, under force (120±6) H-160 mm.

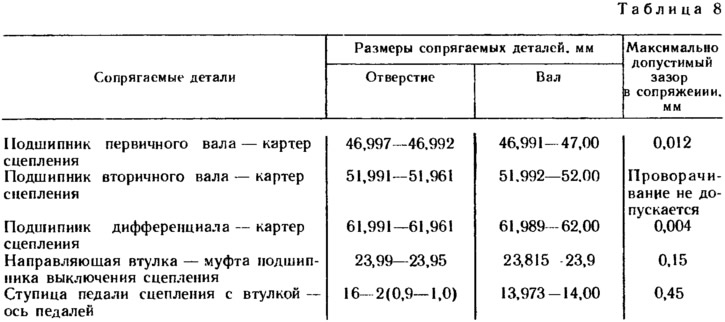

The dimensions of the main mating parts and the limits of permissible wear in operation are given in Table. 8.