- keys "on 10", "at 12" And "at 17"

- screwdriver

Before starting work: Remove the corresponding wheel.

If there are scuffs, deep scratches and other defects on the working surface of the disc that increase pad wear and reduce braking efficiency, replace the disc. In specialized workshops, such a disc can be machined and polished on both sides to the same depth, but after processing, the thickness of the disc must not be less than the minimum allowable.

The minimum permissible thickness of the brake disc is A=7.8 mm. If the disc is thinner, it must be replaced. The axial runout of the brake disc surface must not exceed 0.15 mm. At the same time, keep in mind that disc measurements should be carried out in specialized workshops. Measuring the disk, for example with a caliper, will not give real results.

Recommendation. Replace both brake discs at the same time.

1. Remove the rubber seal from the bracket along with the hose.

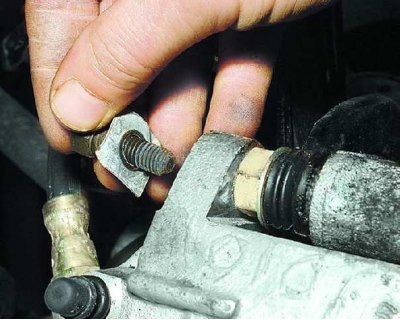

2. Use a screwdriver to bend the antennae of the lock washers of the two caliper mounting bolts.

3. Unscrew the two caliper mounting bolts, holding the guide pins by the hex keys with a wrench.

4. Remove bolts together with lock plates.

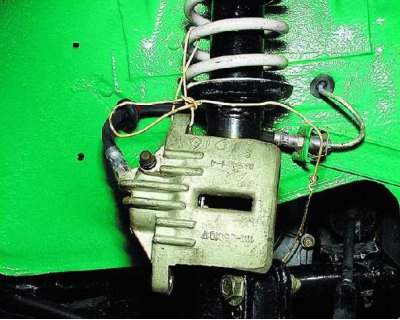

5. Remove the caliper from the shoe guide without disconnecting the brake hose from it (see subsection 7.1.1.).

6. Hang the caliper on a rope or wire from the front suspension spring. At the same time, make sure that the brake hose is not twisted and is not too tight.

7. Remove the brake pads. Mark them so that they can be installed in their original places during assembly.

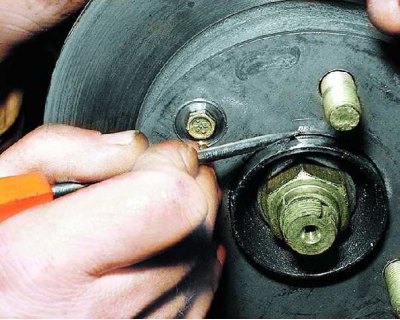

8. Use a screwdriver to bend the tab of the retaining plate of the upper bolt of the guide pads.

9. Remove the lower bolt securing the shoe guide to the steering knuckle. Please note: there is a spring washer under it.

10. Unscrew the upper mounting bolt and, by pulling it out, remove the shoe guide.

11. Moisten with fluid like WD-40 the junction of the disc with the hub and the fastening bolt. Wait a while for the rust to dissolve and remove the dirt and rust.

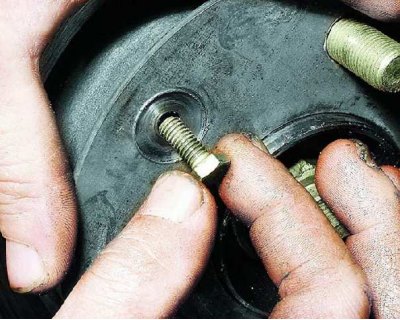

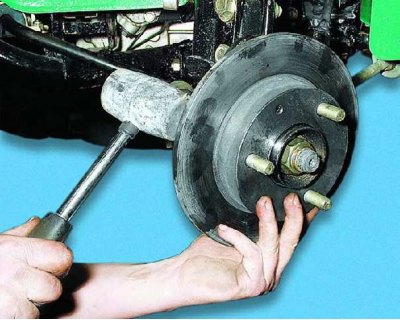

12. Loosen the brake disc mounting bolt.

13. If difficult to remove, tap the disc with a rubber or polymer mallet.

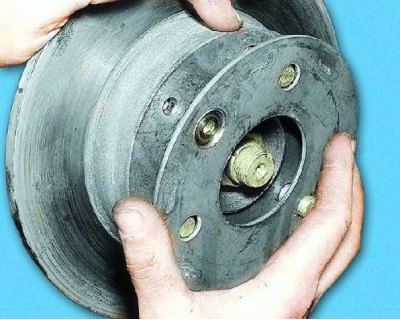

14. Remove the distance ring.

15. Remove the brake disc.

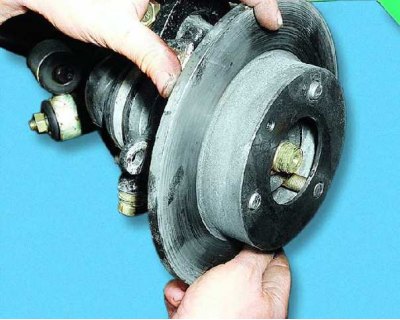

16. Before installing the old disc, file off the shoulders formed as a result of disc wear on both sides with a file.

17. Install the brake disc in the reverse order of removal. At the same time, lock the upper mounting bolt of the guide by bending the tab of the locking plate.